Circulating drying system measuring system for gummed bamboo mats

A drying system and technology for glueing bamboo, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problem of uneven degumming and gluing, damage to bamboo mat and glue, uneven drying, etc. problem, to achieve the effect of improving drying effect, reducing fluidity, uniform and rapid solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below with reference to the drawings and specific embodiments.

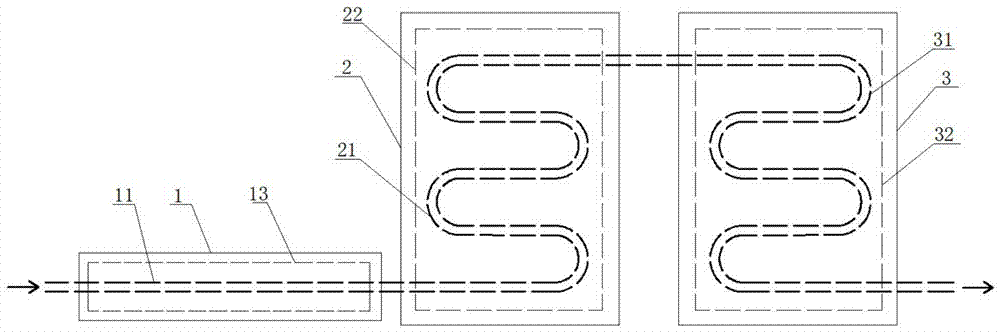

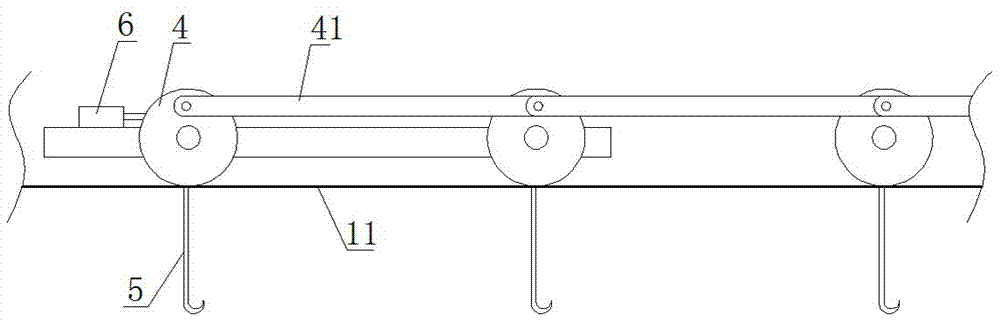

[0035] See figure 1 , A glued bamboo mat circulation drying system, comprising a quick-setting drying room 1, a slow-setting drying room 2 and a cooling room 3 arranged in sequence, the quick-setting drying room 1, the slow-setting drying room 2 and A first conveying track 11, a second conveying track 21, and a third conveying track 31 are respectively suspended in the cooling room 3; the first conveying track 11, the second conveying track 21 and the third conveying track 31 are connected in sequence; The first conveying track 11 extends linearly along the length direction of the quick-setting drying room 1; the second conveying track 21 and the third conveying track 31 are bent in a horizontal S shape in the slow-setting drying room 2 and the cooling room 3, respectively.

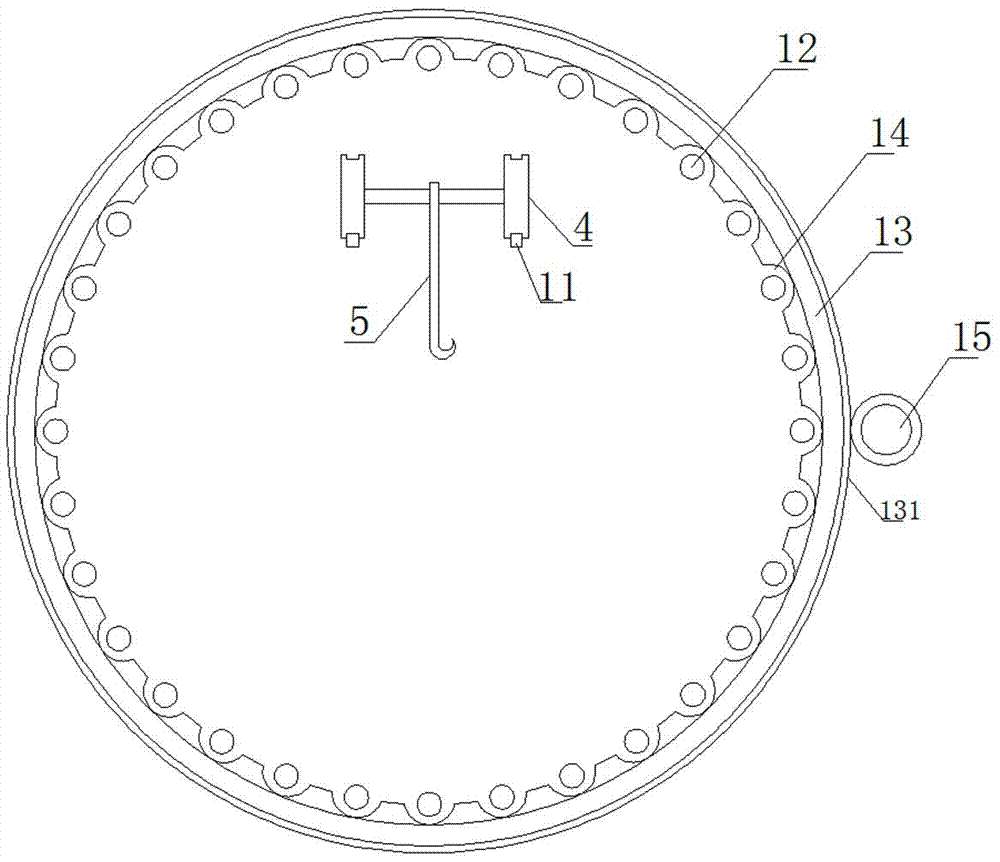

[0036] See figure 2 , The quick-setting drying room 1 is uniformly densely distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com