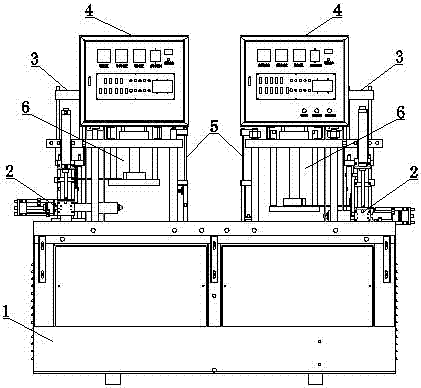

Pneumatic double-station cylinder-free wax injection machine

A dual-station, wax injection machine technology, applied in the field of wax injection machines, can solve the problems of short service life of the wax cylinder, small operation space of the press mold, and low operation safety, so as to protect the safety of the mold and fast response speed , the effect of large operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

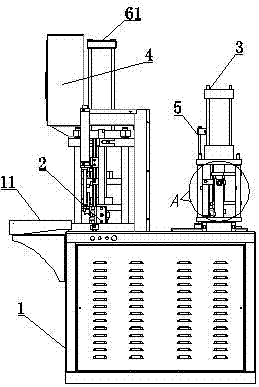

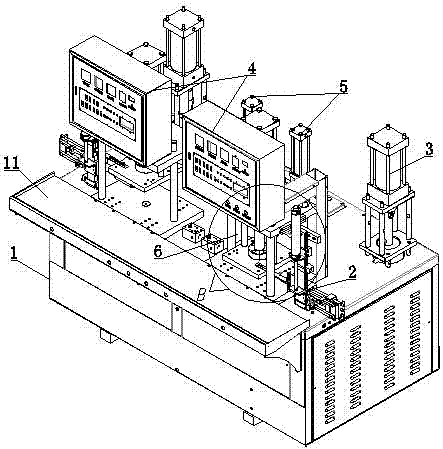

[0027] Such as Figure 1-3 In the illustrated embodiment, a pneumatic double-station cylinder-free wax injection machine includes a frame 1, a wax injection device 2, a wax feeding tank 3, a control box 4, and a wax storage tank 5 symmetrically arranged on the top surface of the frame 1. , Compression molding device 6, characterized in that: the wax injection device 2 is driven by a cylinder to cooperate with the hand wheel to fine-tune the movement of six degrees of freedom, the wax feeding cylinder 3 is hydraulically driven, and the control box 4 is installed in On the top of the compression molding device 6, a worktable 12 is arranged on the top surface of the frame 1, and the worktable 12 is arranged coplanar with the operation table 11, and the surface of the worktable 12 is provided with a positioning hole 13 with a diameter of 5mm, The wax feeding bath 3 includes a pipeline connecting portion 31, a limiting plate 32, a wax feeding bath fixing rod 33, and a wax feeding ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com