A kind of preparation method of three-dimensional manganese dioxide airgel

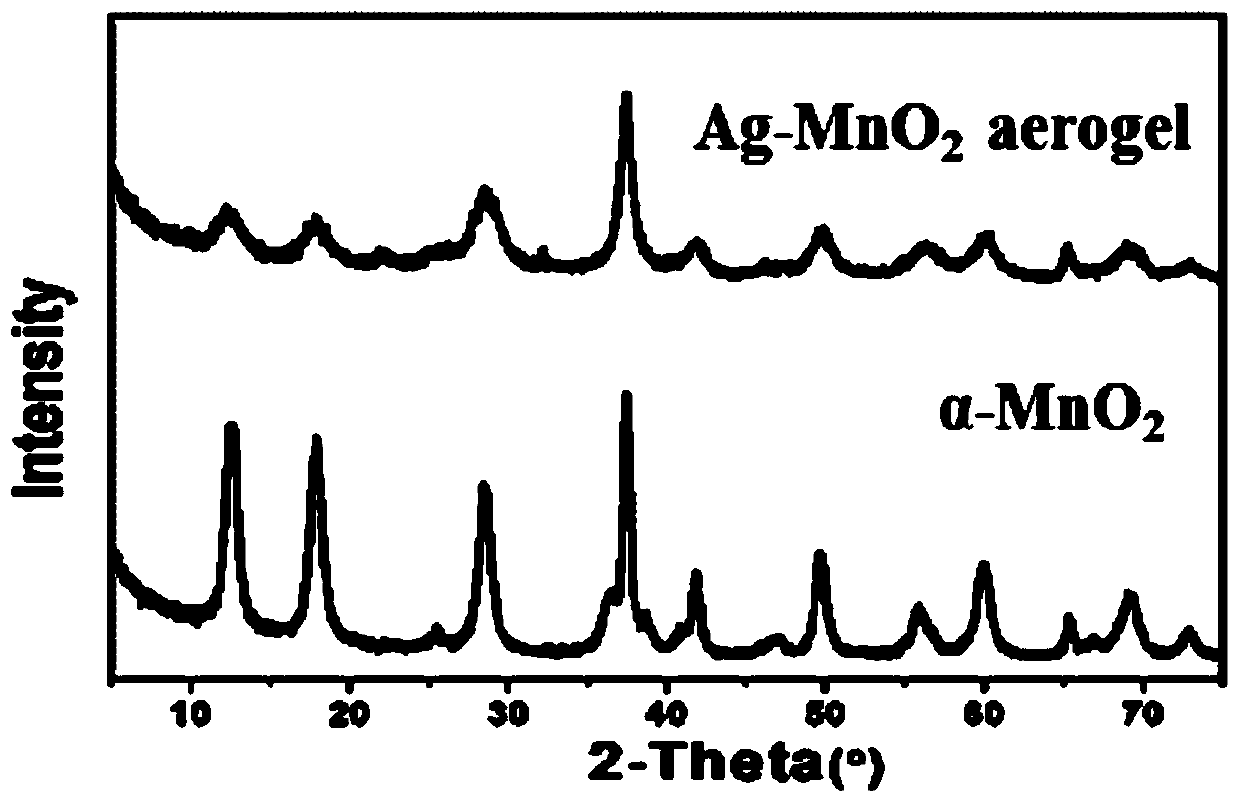

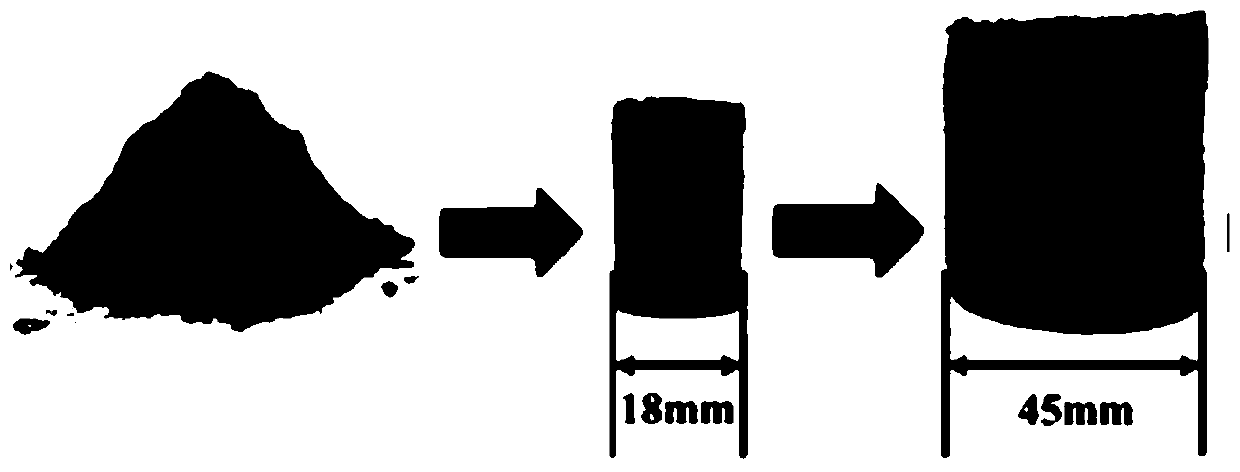

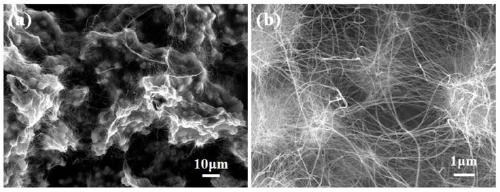

A technology of manganese dioxide and aerogels, which is applied in chemical instruments and methods, manganese oxide/manganese hydroxide, metal/metal oxide/metal hydroxide catalysts, etc., can solve the limitation of manganese dioxide aerogels widely application, crystal form of manganese dioxide cannot be controlled, and organically modified molecules remain, so as to achieve the effects of easy scale-up experiment, improvement of poor conductivity, and improvement of electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The formula for adding manganese dioxide nanowires to the lining of a 100mL capacity hydrothermal kettle: after adding 3.38g of manganese (II), 4.69g of ammonium persulfate and 10.58g of ammonium sulfate, add 70mL of ultrapure water to dissolve, and prepare Form solution A, the molar ratio of manganese sulfate (II): ammonium persulfate: ammonium sulfate is 1:1:4. Stir solution A for 15 minutes until it becomes clear, then add 0.03 g of silver nitrate and stir vigorously to form solution B, which is a black suspension. After sealing the hydrothermal kettle where the solution B was located, it was placed in an oven to react at 140°C for 14 hours, and the hydrothermal reaction was carried out to obtain block solid C. After the hydrothermal kettle was cooled to room temperature, the solid C was taken out from the hydrothermal kettle and soaked in deionized water. During this period, the water was changed continuously. When the pH=7, freeze-dried to obtain 1.75g of airgel ...

Embodiment 2

[0057] The formula for adding manganese dioxide nanowires to the lining of a 100mL capacity hydrothermal kettle: after adding 3.38g of manganese (II), 4.69g of ammonium persulfate and 10.58g of ammonium sulfate, add 70mL of ultrapure water to dissolve, and prepare Form solution A, the molar ratio of manganese sulfate (II): ammonium persulfate: ammonium sulfate is 1:1:4. Stir solution A for 15min until clear, add 0.305g AgNO 3 , after vigorous stirring, it was made into solution B, and solution B was a black suspension. After sealing the hydrothermal kettle where the solution B was located, it was placed in an oven to react at 140°C for 14 hours, and the hydrothermal reaction was carried out to obtain block solid C. After the hydrothermal kettle was cooled to room temperature, the solid C was taken out from the hydrothermal kettle and soaked in deionized water. During this period, the water was changed continuously. When the pH=7, it was freeze-dried to obtain 1.91g of airgel ...

Embodiment 3

[0062] The formula for adding manganese dioxide nanowires to the lining of a 100mL capacity hydrothermal kettle: after adding 3.38g of manganese (II), 4.69g of ammonium persulfate and 10.58g of ammonium sulfate, add 70mL of ultrapure water to dissolve, and prepare Form solution A, the molar ratio of manganese sulfate (II): ammonium persulfate: ammonium sulfate is 1:1:4. Stir solution A for 15min until clear, then add 0.68g AgNO 3 , after vigorous stirring, it was made into solution B, and solution B was a black suspension. After sealing the hydrothermal kettle where the solution B was located, it was placed in an oven to react at 140°C for 14 hours, and the hydrothermal reaction was carried out to obtain block solid C. After the hydrothermal kettle was cooled to room temperature, the solid C was taken out from the hydrothermal kettle and soaked in deionized water. During this period, the water was changed continuously. When the pH was 7, freeze-dried to obtain 2.1 g of airgel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com