Cu-Te (copper-thulium) nanocrystalline/Cu2SnSe3 (copper and tin selenide) electrothermal composite material and preparation method thereof

A composite material and nanocrystal technology, which is applied in the field of Cu-Te nanocrystal/Cu2SnSe3 thermoelectric composite material and its preparation, can solve the problem that the second phase composite is not involved, and achieves improved ZT value, simple process operation, good thermoelectricity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

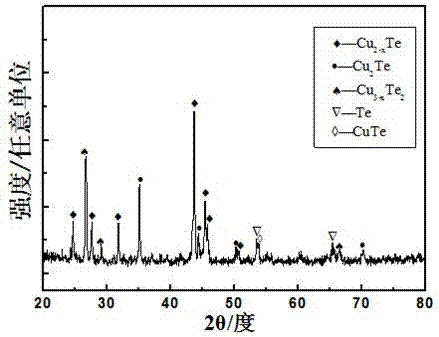

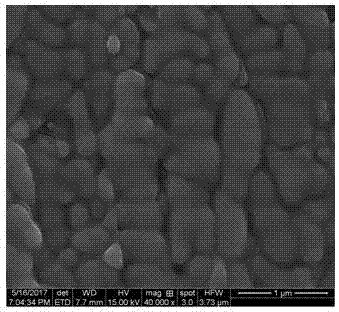

[0040] 1.1 Weigh a total of 12g of high-purity (≥99.9%) copper and tellurium block elements according to the molar ratio of copper block and tellurium block 1.6:1. Rotate to 1500r / min and carry out the melt spinning operation under argon protection (jet pressure 0.02MPa) and induction current frequency 28Hz to obtain strip-shaped samples containing Cu-Te nanocrystals, which are then manually ground into powder;

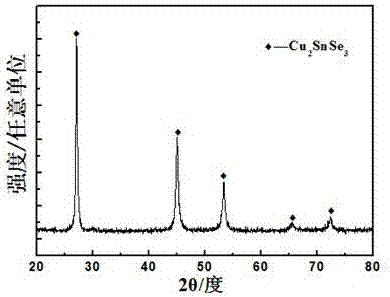

[0041] 1.2 Weigh 15g of high-purity (≥99.9%) copper, tin, and selenium powder elements according to the molar ratio of 2:1:3, mix them evenly and put them into a graphite crucible, and put the graphite crucible containing the sample into a quartz tube In the process, it is vacuum-sealed (vacuum degree less than 0.01MPa); the quartz tube containing the sample is put into a resistance furnace for melting, and the temperature is raised from room temperature to 1000 °C at a heating rate of 5 °C / min during the melting reaction process, and then Insulate for 12 hours, cool...

Embodiment 2

[0046] 2.1 Weigh a total of 12g of high-purity (≥99.9%) copper and tellurium block elements according to the molar ratio of copper block and tellurium block of 1.7:1. Rotate to 2000r / min and carry out the melt spinning operation under argon protection (jet pressure 0.06MPa) and induction current frequency 30Hz to obtain strip-shaped samples containing Cu-Te nanocrystals, which are then manually ground into powder;

[0047] 2.2 Weigh 15g of high-purity (≥99.9%) copper, tin, and selenium powder elements according to the molar ratio of 2:1:3, mix them evenly and put them into a graphite crucible, and put the graphite crucible with the sample into the quartz tube In the process, it is vacuum-sealed (vacuum degree less than 0.01MPa); the vacuum-sealed quartz tube containing the sample is put into a resistance furnace for melting, and the temperature is raised from room temperature to 5°C / min during the melting reaction process. 900°C, then keep it warm for 12h, after the end of th...

Embodiment 3

[0052] 3.1 Weigh a total of 12g of high-purity (≥99.9%) copper and tellurium block elements according to the molar ratio of copper block and tellurium block 1.8:1. Rotate to 3000r / min and carry out the melt spinning operation under argon protection (jet pressure 0.04MPa) and induction current frequency 35Hz to obtain strip-shaped samples containing Cu-Te nanocrystals, which are then manually ground into powder;

[0053] 3.2 Weigh 15g of high-purity (≥99.9%) copper, tin, and selenium powder elements according to the molar ratio of 2:1:3, mix them evenly and put them into a graphite crucible, and put the graphite crucible with the sample into the quartz tube In the process, it is vacuum-sealed (vacuum degree less than 0.01MPa); the vacuum-sealed quartz tube containing the sample is put into a resistance furnace for melting, and the temperature is raised from room temperature to 5°C / min during the melting reaction process. 1000°C, then keep warm for 10h, then cool down to 600°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com