Preparation method of creatinol phosphate

A technology of inositol phosphate and inositol phosphate, applied in the field of preparation of inositol phosphate, can solve problems such as lack of solutions, and achieve the effects of easy biochemical treatment, lowering reaction temperature and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add 150g ethyl acetate, 20g myo-inositol phosphate, p-toluenesulfonic acid 0.2g, dicyclohexylcarbodiimide (DCC) 10g successively in the 500mL flask of belt reflux device, under stirring state, reaction temperature is 90 ℃, reflux reaction for 3 hours, distill off 120 g of ethyl acetate under reduced pressure, and obtain a white solid after cooling and filtering. Add the solid to 100 g of distilled water, heat to 60° C. and filter while hot, cool to room temperature, filter and dry to obtain 17 g of white inositol phosphate, and the yield is 93% based on inositol phosphate.

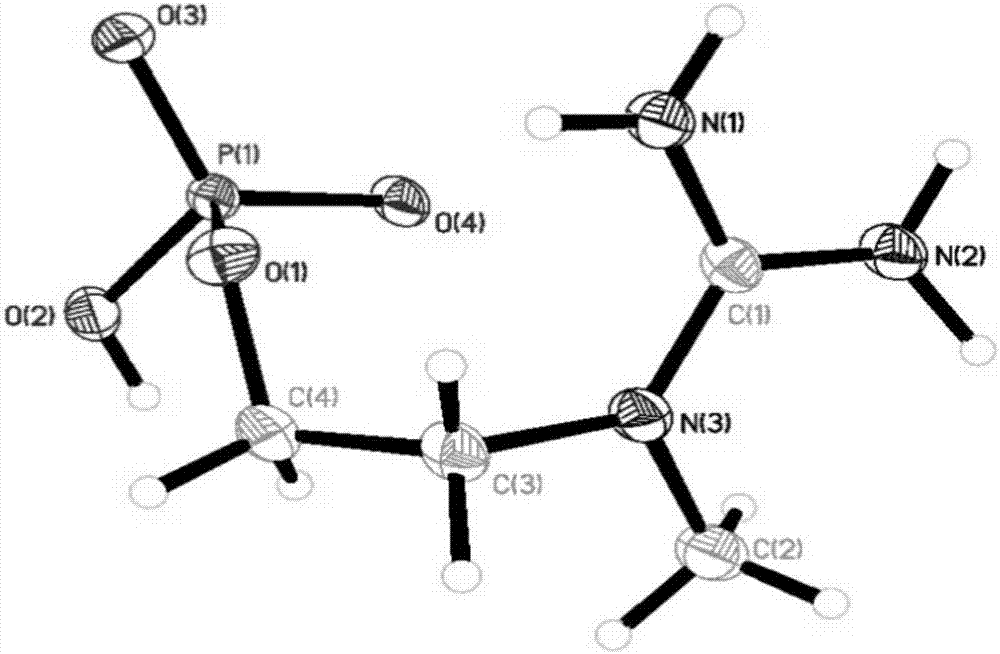

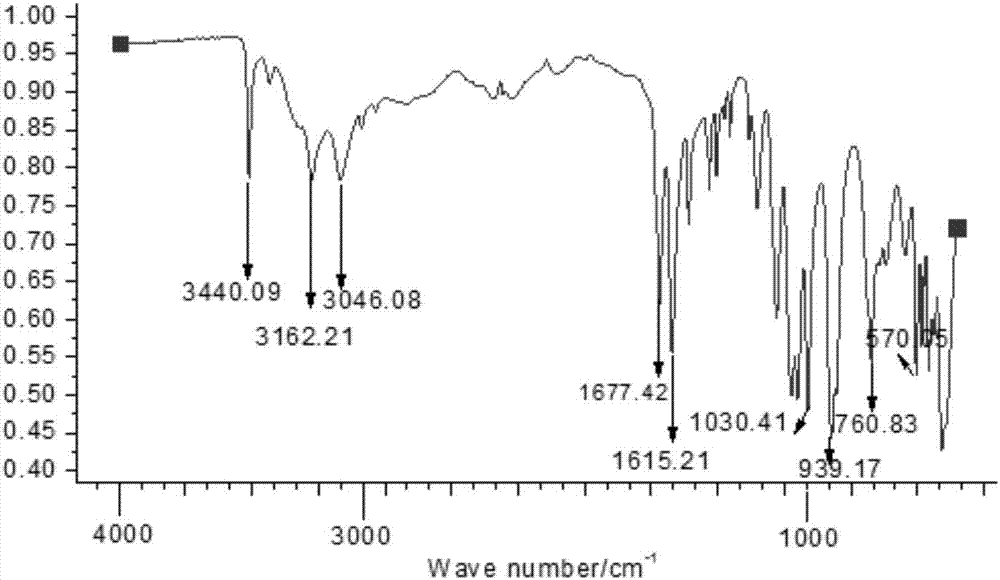

[0047] Depend on figure 1 and figure 2 It can be seen that the product prepared by the present invention is inositol phosphate.

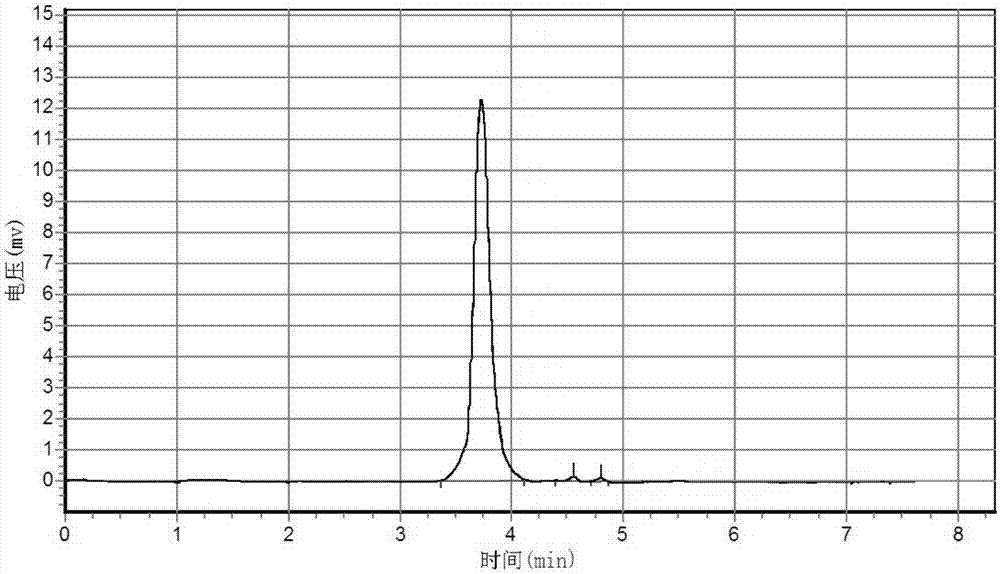

[0048] image 3 It is the high-efficiency liquid chromatogram of the synthetic product of embodiment 1, and table 1 is the analytical result table. Depend on image 3 As can be seen from Table 1, the purity of the prepared inositol phosphate is higher than 99%.

[...

Embodiment 2

[0052]Add 150g ethyl acetate, 20g myo-inositol phosphate, p-toluenesulfonic acid 0.2g, dicyclohexylcarbodiimide (DCC) 20g successively in a 500mL flask with a reflux device, and under stirring, the reaction temperature is 87 ℃, reflux reaction for 3 hours, distilled off 122 g of ethyl acetate under reduced pressure, cooled and filtered to obtain a white solid. The solid was added to 100g of distilled water, heated to 60°C and filtered while hot, cooled to room temperature, filtered and dried to obtain 16.8g of white inositol phosphate, and the yield in terms of inositol phosphate was 92%; the prepared inositol phosphate had a purity higher than 99%.

Embodiment 3

[0054] Add 100g of ethyl acetate, 20g of myo-inositol phosphate, 0.1g of p-toluenesulfonic acid, and 10g of dicyclohexylcarbodiimide (DCC) successively in a 500mL flask with a reflux device. Under stirring, the reaction temperature is 88 °C, reflux reaction for 3 hours, distill off 114 g of ethyl acetate under reduced pressure, cool and filter to obtain a white solid. Add the solid to 100 g of distilled water, heat to 60°C and filter while it is hot, cool to room temperature, filter and dry to obtain 15 g of white inositol phosphate, and the yield is 82% in terms of inositol phosphate; the purity of the prepared inositol phosphate is higher than 97% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com