Thick chlorinated rubber antirust paint

A technology of chlorinated rubber and anti-rust paint, which is applied in the direction of rubber derivative coatings, coatings, anti-corrosion coatings, etc., can solve the problems of poor flexibility, adhesion, and poor brushability, etc., and achieve low cost and environmental friendliness , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

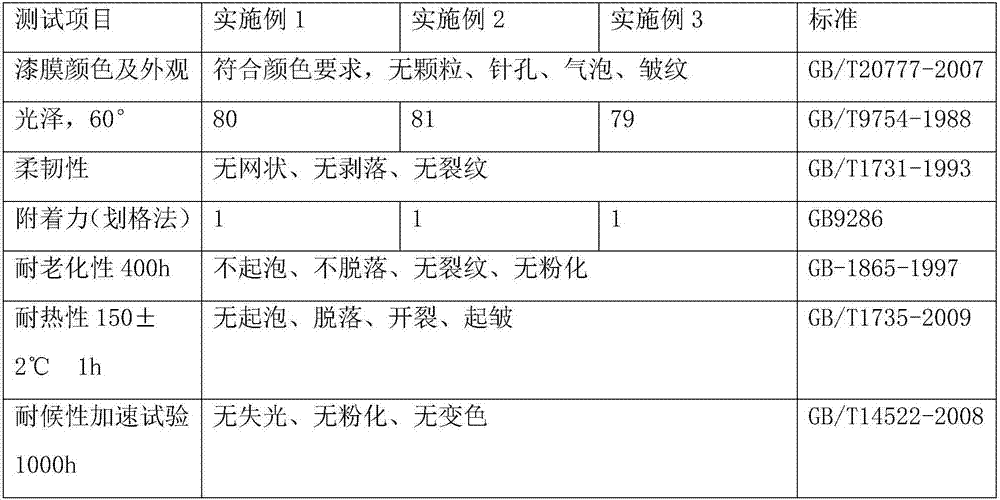

Examples

Embodiment 1

[0017] A thick coating type chlorinated rubber antirust paint, which is made of the following components in parts by weight: 30 parts of chlorinated rubber, 50 parts of chlorinated polyolefin, 5 parts of chlorinated paraffin, 30 parts of solvent, xylene and mixed aromatic hydrocarbons S-100 is mixed according to 1:1, 15 parts of mica powder, 5 parts of modified nano-silica, 12 parts of rutile titanium dioxide, 0.5 part of wetting and dispersing agent BYK-104S, 0.5 part of leveling agent BYK-354, Foam agent BYK-141 0.5 part, stabilizer dibutyltin dilaurate 0.1 part, anti-settling agent modified organic bentonite 1 part.

[0018] Modified nano-silica is obtained by mixing 4.0 generation polyamide-amine dendrimers with nano-SiO2 powder in a weight ratio of 20:12, and modified after magnetic stirring and ultrasonic oscillation under the protection of inert gas. .

Embodiment 2

[0020] A thick coating type chlorinated rubber antirust paint, which is made of the following components in parts by weight: 40 parts of chlorinated rubber, 50 parts of chlorinated polyolefin, 5 parts of chlorinated paraffin, 30 parts of solvent, xylene and mixed aromatic hydrocarbons S-100 is mixed according to 1:1, 15 parts of mica powder, 5 parts of modified nano-silica, 12 parts of rutile titanium dioxide, 0.5 part of wetting and dispersing agent BYK-104S, 0.5 part of leveling agent BYK-354, Foam agent BYK-141 0.5 part, stabilizer dibutyltin dilaurate 0.1 part, anti-settling agent modified organic bentonite 1 part.

Embodiment 3

[0022] A thick coating type chlorinated rubber antirust paint, which is made of the following components in parts by weight: 50 parts of chlorinated rubber, 50 parts of chlorinated polyolefin, 5 parts of chlorinated paraffin, 30 parts of solvent, xylene and mixed aromatic hydrocarbons S-100 is mixed according to 1:1, 15 parts of mica powder, 5 parts of modified nano-silica, 12 parts of rutile titanium dioxide, 0.5 part of wetting and dispersing agent BYK-104S, 0.5 part of leveling agent BYK-354, Foam agent BYK-141 0.5 part, stabilizer dibutyltin dilaurate 0.1 part, anti-settling agent modified organic bentonite 1 part.

[0023] Construction methods

[0024] One-component, direct use

[0025] thinner chlorinated rubber thinner

[0026] Spraying method airless spraying, air spraying, brushing, roller coating optional

[0027] Nozzle hole 0.4-0.5mm or 2-3mm

[0028] The ejection pressure is 10-15 or 0.3-0.4Mpa

[0029] Coating film thickness wet film 600μm / pass

[0030] Sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com