High-temperature-resistant resin-based friction material

A technology of high temperature resistant resin and friction material, applied in friction linings, gear shifting mechanisms, other chemical processes, etc., can solve the problems of low safety factor, unstable friction coefficient, poor high temperature resistance performance, etc., and achieve a wide range of raw material sources. , the effect of friction coefficient stability improvement, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

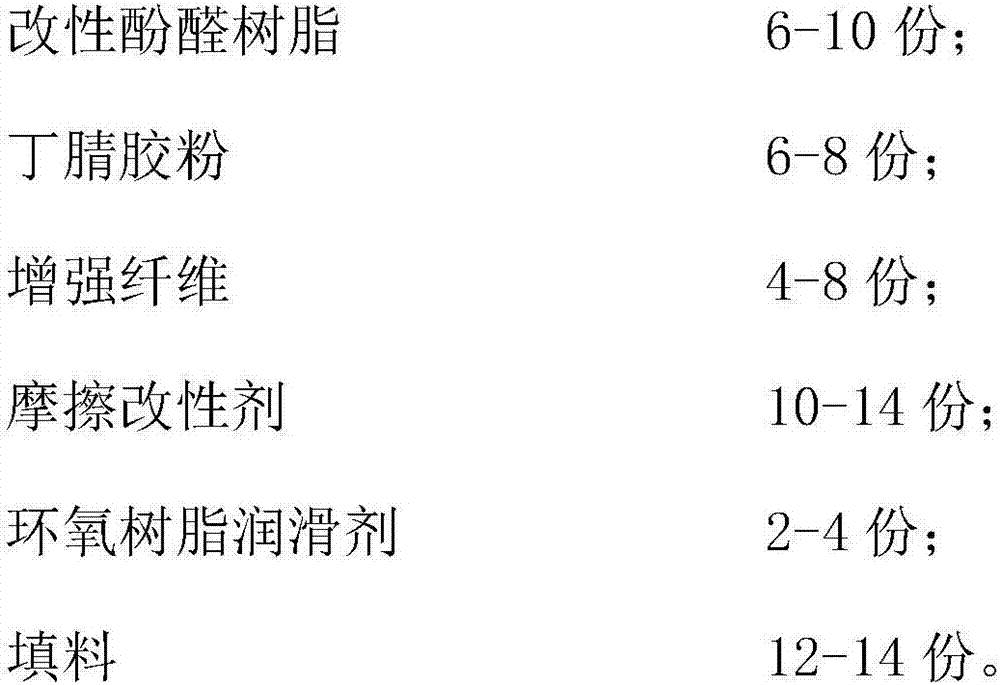

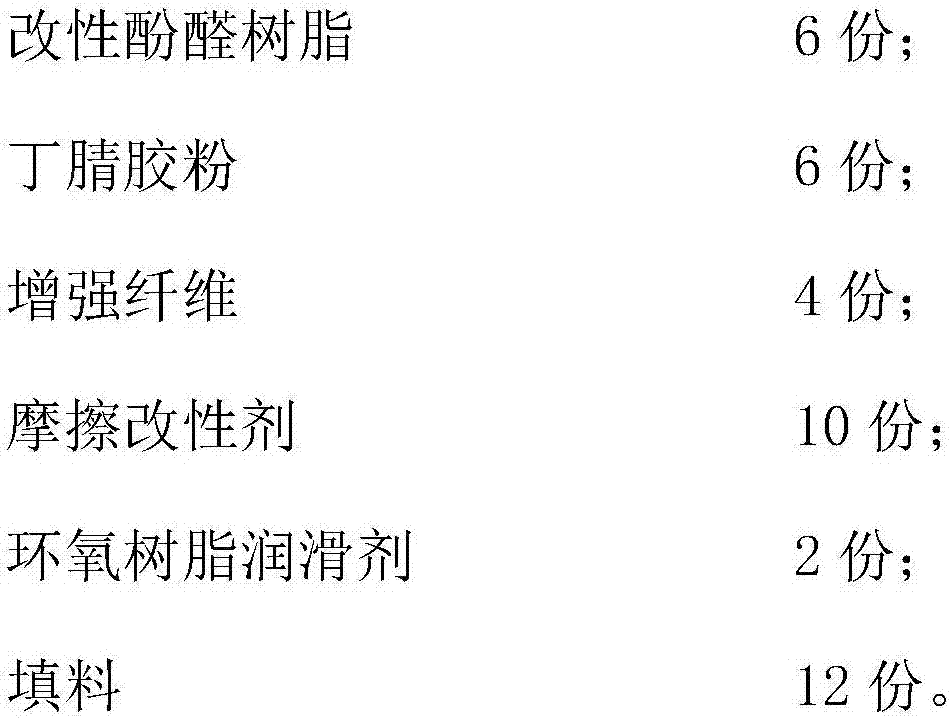

[0026] A high temperature resistant resin-based friction material, comprising the following raw materials in parts by weight:

[0027] 6 parts of modified phenolic resin;

[0028] 6 parts of nitrile rubber powder;

[0029] Reinforcing fiber 4 parts,

[0030] Wherein, the reinforcing fiber is a combination of glass fiber, aramid fiber, and non-asbestos mineral fiber;

[0031] Friction modifier 10 parts,

[0032] Wherein, the friction modifier is a composition of flake graphite, artificial graphite, molybdenum disulfide, antimony trisulfide, potassium titanate whiskers, and calcium sulfate whiskers;

[0033] 2 parts of epoxy resin lubricant;

[0034] Filling 12 parts,

[0035] Wherein, the filler is a combination of silica fume, friction powder, expanded vermiculite and kaolin.

Embodiment 2

[0037] A high temperature resistant resin-based friction material, comprising the following raw materials in parts by weight:

[0038] 8 parts of modified phenolic resin;

[0039] 7 parts of nitrile rubber powder;

[0040] Reinforcing fiber 6 parts,

[0041] Wherein, the reinforcing fiber is a combination of glass fiber, aramid fiber, and non-asbestos mineral fiber;

[0042] 12 parts of friction modifier,

[0043] Wherein, the friction modifier is a composition of flake graphite, artificial graphite, molybdenum disulfide, antimony trisulfide, potassium titanate whiskers, and calcium sulfate whiskers;

[0044] 3 parts of epoxy resin lubricant;

[0045] Filling 13 parts,

[0046] Wherein, the filler is a combination of silica fume, friction powder, expanded vermiculite and kaolin.

Embodiment 3

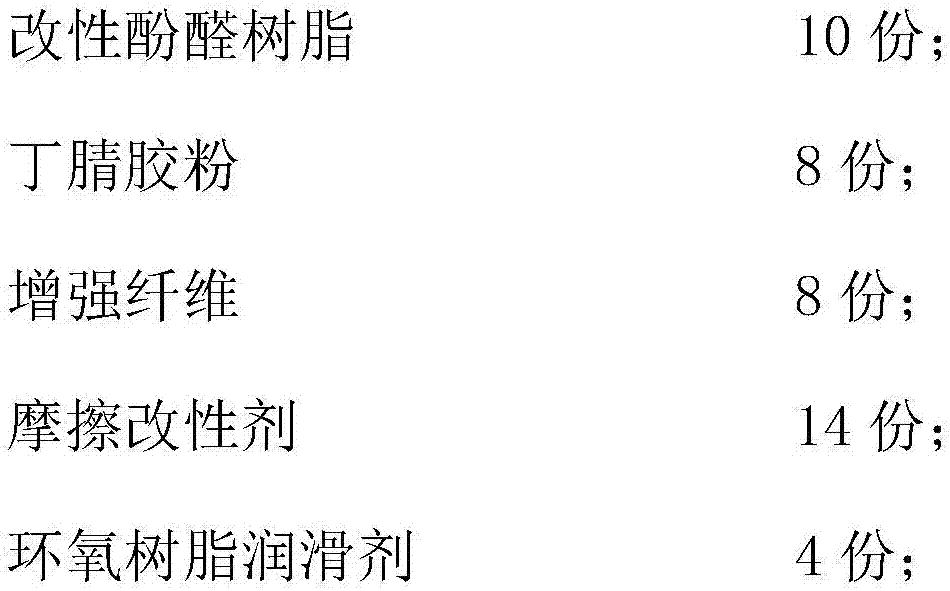

[0048] A high temperature resistant resin-based friction material, comprising the following raw materials in parts by weight:

[0049] 10 parts of modified phenolic resin;

[0050] 8 parts of nitrile rubber powder;

[0051] Reinforcing fiber 8 parts,

[0052] Wherein, the reinforcing fiber is a combination of glass fiber, aramid fiber, and non-asbestos mineral fiber;

[0053] 14 parts of friction modifier,

[0054] Wherein, the friction modifier is a composition of flake graphite, artificial graphite, molybdenum disulfide, antimony trisulfide, potassium titanate whiskers, and calcium sulfate whiskers;

[0055] 4 parts of epoxy resin lubricant;

[0056] Filling 14 parts,

[0057] Wherein, the filler is a combination of silica fume, friction powder, expanded vermiculite and kaolin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com