Device and method for chopped fiber continuous orientation

A chopped fiber and orientation technology, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems of low fiber orientation, low output efficiency, and increased processes, and achieve high fiber orientation, high orientation efficiency, and easy operation. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

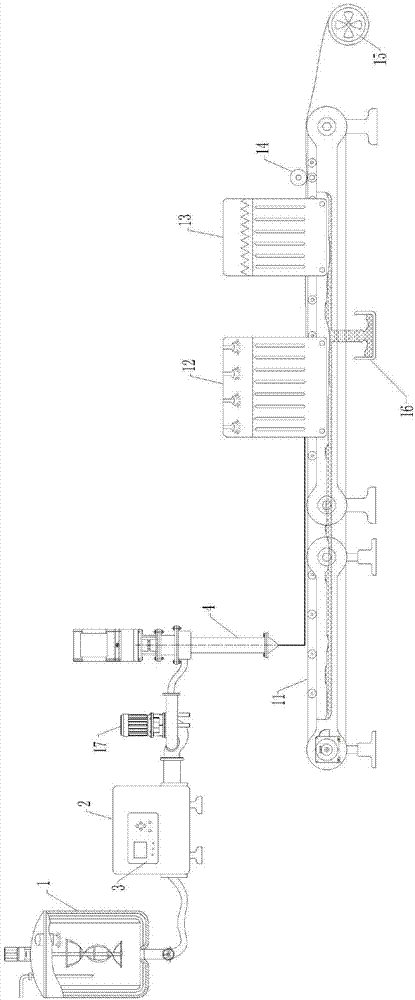

[0040] See Figure 1 to Figure 2 The device for continuous orientation of chopped fibers in this embodiment is composed of a material preparation unit, an orientation device and a separation unit, specifically:

[0041] The material preparation unit is composed of a stirred tank 1 and a liquid storage tank 2 connected by pipes. The composite liquid formed by the chopped fiber and the dispersion medium is stirred through the stirred tank 1 to obtain the chopped fiber suspension and flow into the storage tank 2; The liquid tank 2 is equipped with an ultrasonic generator 3, and the ultrasonic effect of the ultrasonic generator 3 can not only remove the bubbles in the chopped fiber suspension in the storage tank 2, but also avoid the fiber settling in the chopped fiber suspension After that, the chopped fiber suspension in the liquid storage tank 2 is pumped into the orientation device through the motor pump 17 through the draft tube;

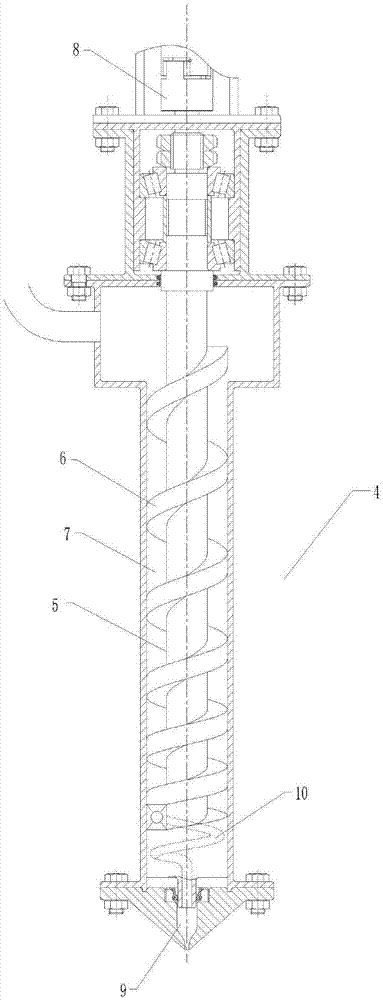

[0042] The orientation device is a vertical scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com