Reducing Heating Of A Particulate Filter During A Regeneration Event

A particulate filter and particulate trap technology, which is applied in the direction of machines/engines, vehicle components, engine components, etc., and can solve problems such as particulate filter material combustion and thermal damage to surrounding components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

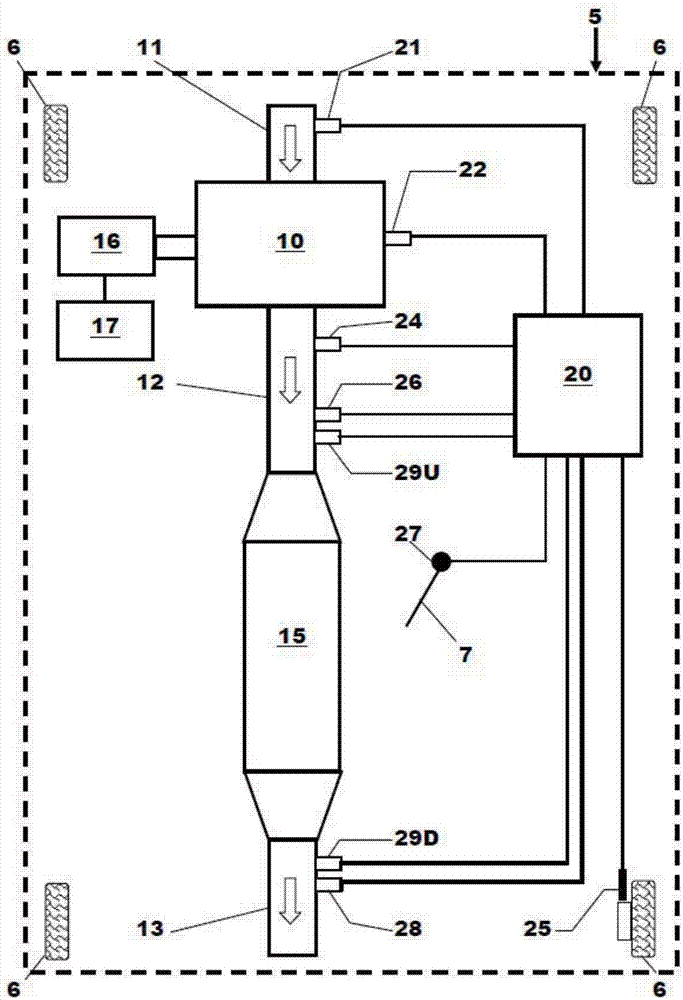

[0038] refer to figure 1 , shows a mild hybrid motor vehicle 5 with four wheels 6 , a direct injection diesel engine 10 and an electronic controller 20 .

[0039] The engine 10 is arranged to receive air through an air intake 11 and, although not shown, in most cases the airflow to the engine 10 is compressed by a supercharger or turbocharger before the airflow flows into the engine 10 In order to improve the efficiency of the engine 10 .

[0040] Exhaust from the engine 10 flows through a first or upstream portion 12 of the exhaust system to a particulate filter in the form of a diesel particulate filter (DPF) 15 and after passing through the DPF 15 the exhaust passes through a second part of the exhaust system. Or the downstream portion 13 flows out to atmosphere.

[0041] It should be understood that other emission control devices or noise suppression devices may be present in the gas flow path from engine 10 to the point where the gas flow exits to atmosphere.

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com