Filament positioning system and filament positioning method

A positioning system and positioning method technology, applied in image data processing, instruments, discharge tubes, etc., can solve the problems of low efficiency, waste of resources, dim filament brightness, etc., to reduce labor time and labor intensity, reduce labor intensity and Labor time, accurate filament positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

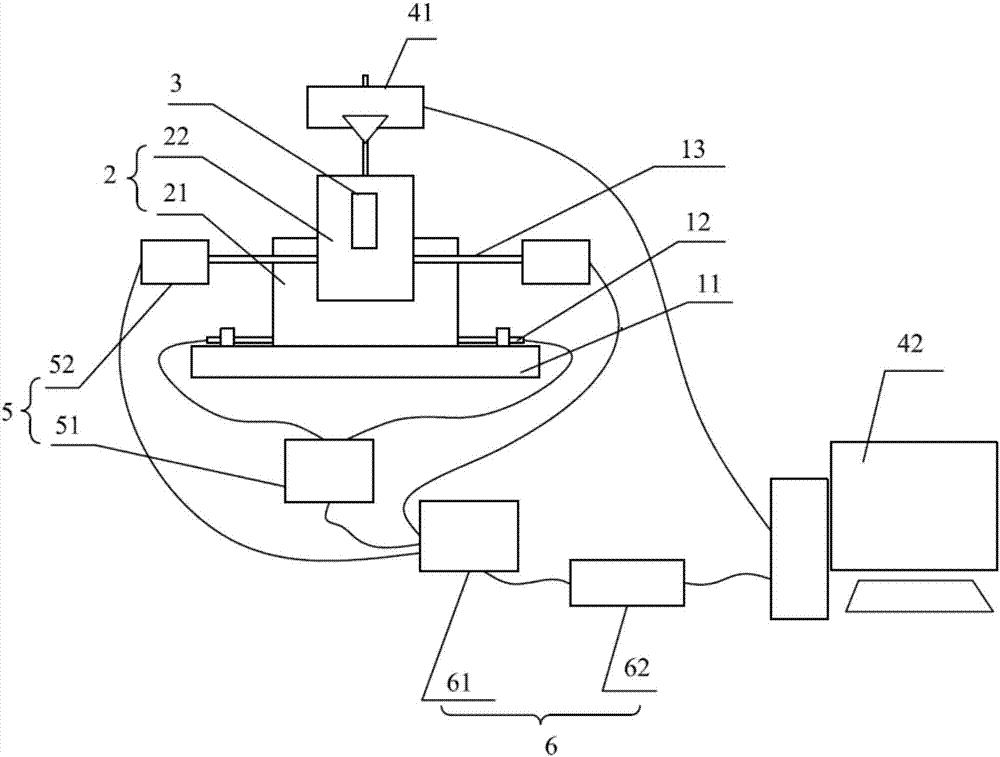

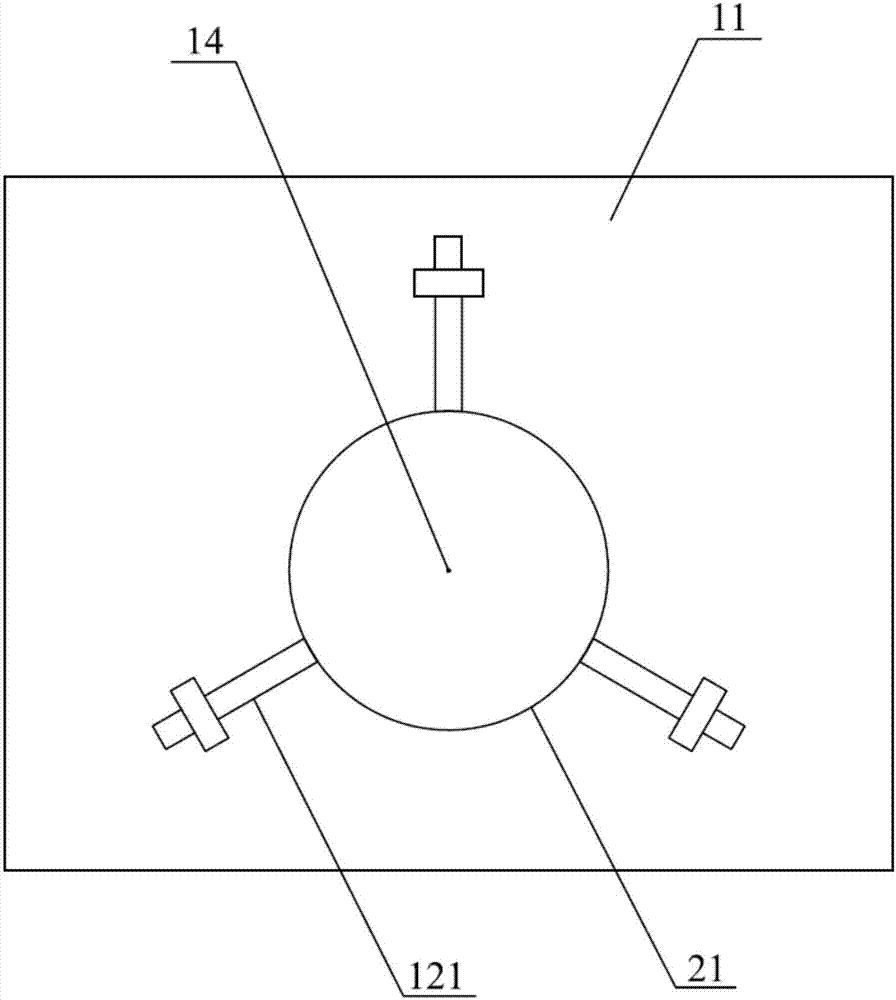

[0070] Such as figure 1 and 2 As shown, Embodiment 1 of the present invention provides a filament positioning system, including a bottom plate 11 , a first positioning adjustment mechanism 12 , a second positioning adjustment mechanism 13 , a detection module, a driving assembly 5 and a control assembly 6 . The bottom plate 11 is used to fix the first positioning adjustment mechanism and the filament seat 2; the first positioning adjustment mechanism 12 is used to position and fix different types of filament seats 2, and the second adjustment mechanism 13 is used to adjust the positioning of different types of filaments 3 , so that this filament positioning system is suitable for the positioning of different types of filaments 3; the detection module is used to detect the parameters required for adjusting the filament 3 and the filament holder 2; the drive assembly 5 is used to drive the first positioning adjustment mechanism 12 and the second positioning The adjustment mecha...

Embodiment 2

[0085] Embodiment 2 of the present invention provides a filament positioning method, which realizes the positioning of the filament 3 through manual adjustment, including the following steps:

[0086] Step 1: install the filament holder 2 and the filament 3 on the bottom plate 11 and the filament holder 2 respectively;

[0087] For the selected filament 3 that needs to be replaced, select a suitable filament holder 2 according to the type of the filament 3 . The filament holder 2 includes a filament positioning seat 22 and a filament base 21 that come with the electron microscope. The filament 3 is mounted on the filament positioning seat 22 through four connecting screws, the filament positioning seat 22 is mounted on the filament base 21 , and the filament base 21 is placed on the bottom plate 11 .

[0088] Step 2: The detection module displays the position information of the filament holder 2 and the filament 3;

[0089] The detection module may include an image acquisitio...

Embodiment 3

[0096] Embodiment 3 of the present invention provides a filament positioning method. The positioning of the filament 3 is realized in a semi-automatic manner. The steps are roughly the same as in Embodiment 2. The difference from Embodiment 2 is that the first positioning is driven by the drive assembly in steps 3 and 4. The adjustment mechanism and / or the second positioning adjustment mechanism work, specifically:

[0097]Step 3: Manually drive the driving assembly 5, so that the driving assembly 5 drives the first positioning adjustment mechanism 12 to adjust the position of the filament holder 2, so that the axis of the filament holder 2 passes through the second positioning center 14;

[0098] According to the pressure value of each pressure sensor in the position information, manually drive the first driving assembly 51, specifically, drive the first motor, so that the first motor drives each positioning rod 121 to move simultaneously, when each pressure value is greater t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com