Method For Producing Semiconductor Epitaxial Wafer, Semiconductor Epitaxial Wafer, And Method For Manufacturing Solid-State Imaging Element

A manufacturing method, epitaxial wafer technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as insufficient, heavy metal pollution of semiconductor substrates, etc., and achieve the effect of high gettering capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

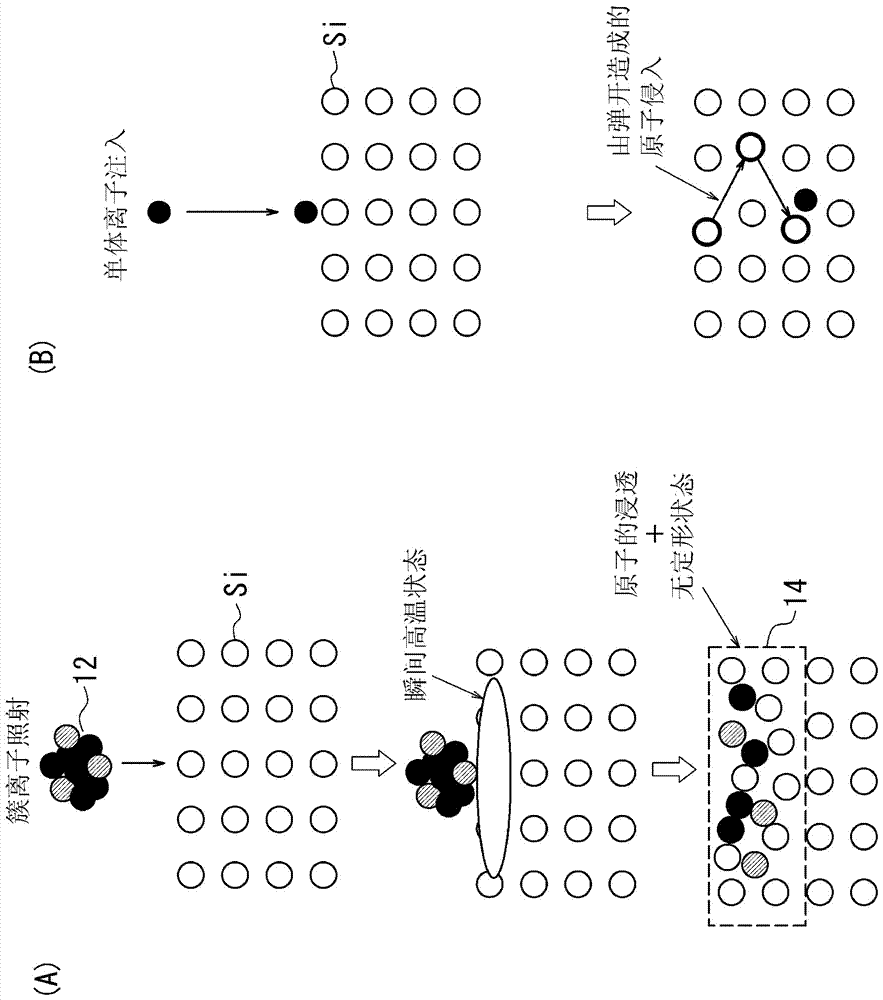

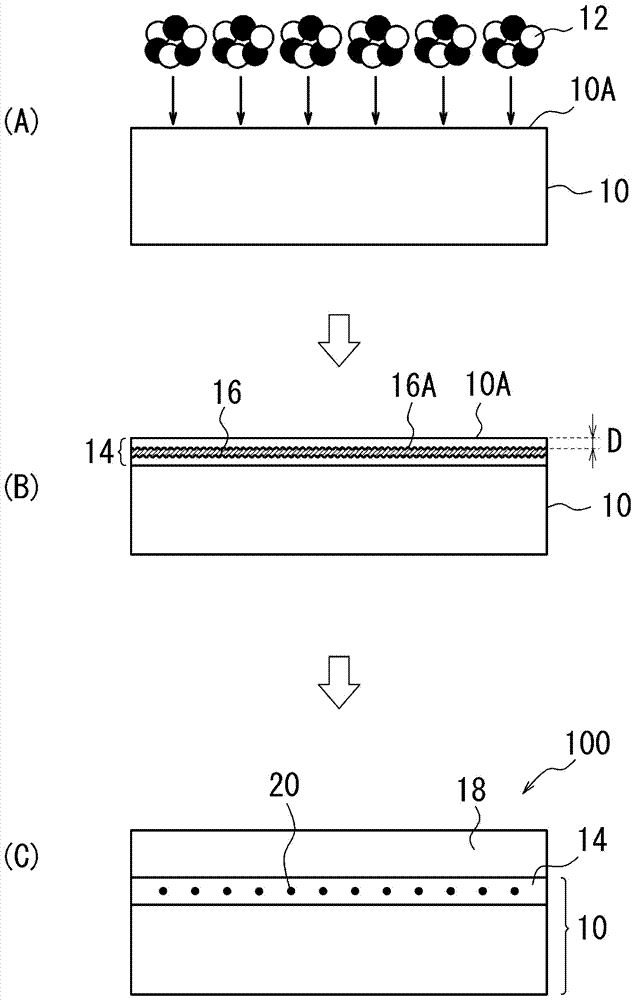

Method used

Image

Examples

experiment example 2

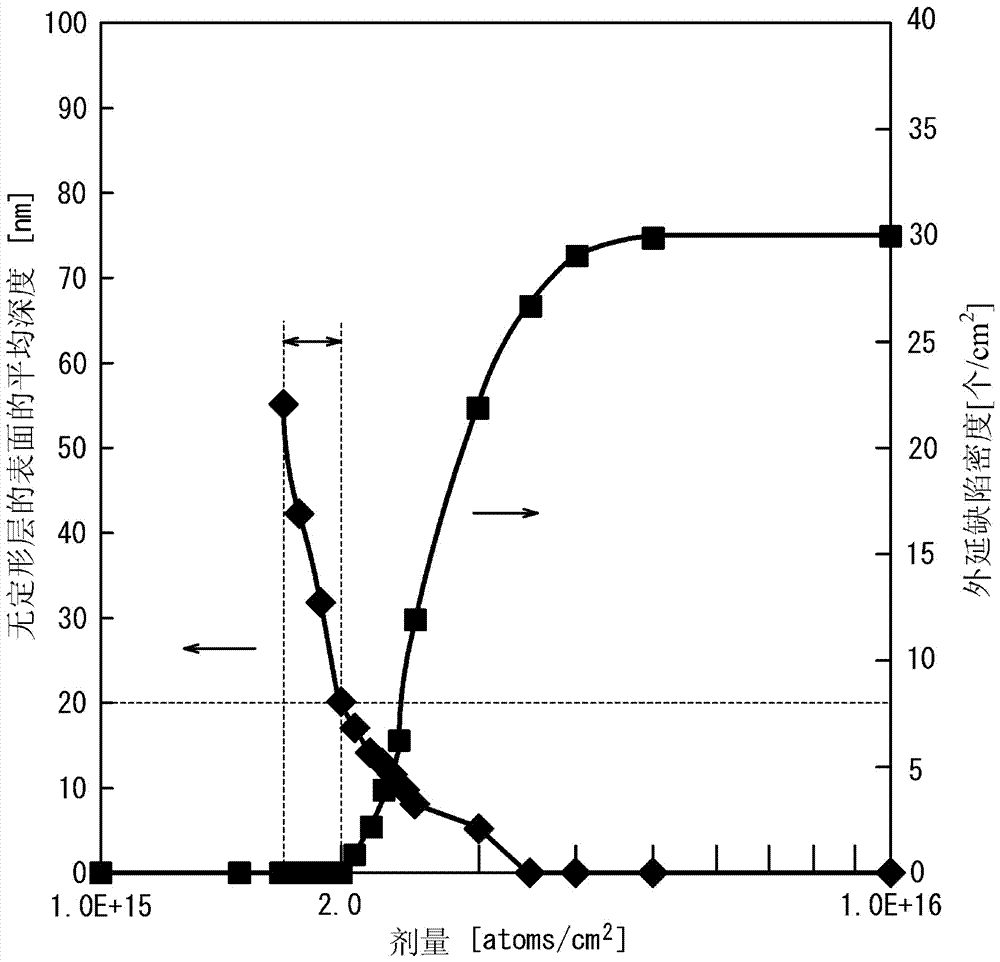

[0098] In addition to carbon dosing such as image 3 As shown in the graph, from 1.0 x 10 15 atoms / cm 2 to 1.0×10 16 atoms / cm 2 Except for the multiple conditions, the same method as in Experimental Example 1 was used to fabricate multiple silicon epitaxial wafers with different dosages.

[0099] The cross section around the modified layer after cluster ion irradiation was observed using TEM. Whether or not an amorphous layer was formed in the modified layer was measured, and when an amorphous layer was formed, the average depth of the surface of the amorphous layer on the semiconductor wafer surface side and the average thickness of the amorphous layer were measured. As a representative example of TEM image, the dose is 1.0×10 15 atoms / cm 2 The situation is shown in Figure 6 (A), the dose is 1.7×10 15 atoms / cm 2 The situation is shown in Figure 6 (B), the dose is 2.0×10 15 atoms / cm 2 The situation is shown in Figure 6 (C), the dose is 3.0×10 15 atoms / cm 2 Th...

experiment example 3

[0107] Except that the species of cluster ion is C generated from cyclohexane 3 h 3 Except clusters, the same experiment as in Experimental Example 2 was carried out to obtain Figure 4 the result of. It can be seen that in this case, it is possible to use 2.2×10 15 atoms / cm 2 The above dosage forms an amorphous layer and obtains high gettering capacity. On the other hand, it is possible to 15 atoms / cm 2 The following doses make the average depth 20 nm or more, thereby sufficiently suppressing the generation of epitaxial defects.

[0108] Also, at a dose of 2.2×10 15 atoms / cm 2 Above and 2.6×10 15 atoms / cm 2 In the range below, black dot-like defects were observed after the epitaxial layer was formed. At doses less than 2.2 x 10 15 atoms / cm 2 In the case of , black dot-like defects were not observed. At doses greater than 2.6 x 10 15 atoms / cm 2 In the case of , black dot-like defects were not observed, but a linear defect layer formed by connecting black dots wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com