Separator for electricity storage device

A technology for power storage devices and separators, which is applied to electrical components, lithium batteries, battery pack components, etc. It can solve the problems of CID start-up time and initial charge-discharge efficiency without evaluation, and achieve excellent battery characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

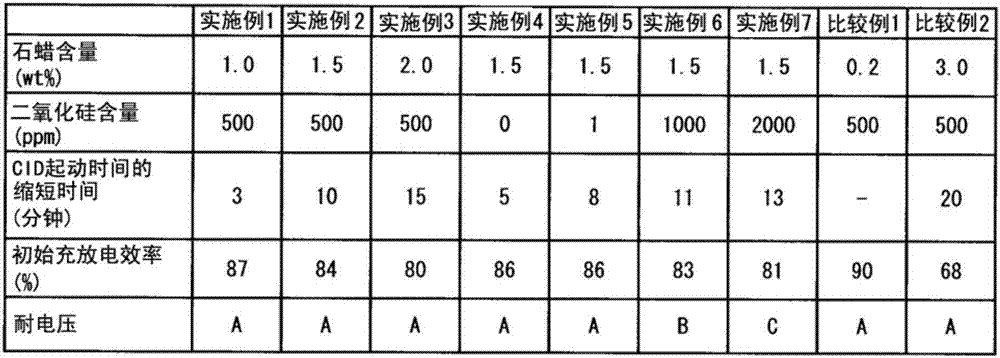

Examples

Embodiment 1

[0153] Using a drum mixer, Mv was 45 parts by mass of high-density polyethylene of a homopolymer of 700,000, 45 parts by mass of high-density polyethylene of a homopolymer of 300,000 Mv, and 45 parts by mass of a homopolymer of 400,000 Mv. 10 parts by mass of a mixture (mass ratio = 4:3) of polypropylene and a homopolymer polypropylene with Mv of 150,000, and 0.0495 parts by mass of silica "LP" (manufactured by TOSOH SILICA CORPORATION.) with an average primary particle diameter of 15 nm Parts (500ppm) were dry blended to obtain a polyolefin mixture.

[0154] To 99 parts by mass of the obtained polyolefin mixture, 1 mass of tetrakis-[methylene-(3',5'-di-tert-butyl-4'-hydroxyphenyl)propionate]methane was added as an antioxidant parts, dry blended again using a drum mixer, thereby obtaining a mixture.

[0155] The resulting mixture was supplied to a twin-screw extruder through a feeder under a nitrogen atmosphere. In addition, liquid paraffin (kinematic viscosity at 37.7...

Embodiment 2

[0159] A polyolefin microporous membrane was obtained in the same manner as in Example 1, except that the extraction conditions in Example 1 were adjusted so that the paraffin content of the microporous membrane obtained by the above measurement method was 1.5 wt%. Various physical properties of the obtained microporous membrane were measured by the methods described above.

Embodiment 3

[0161] A polyolefin microporous membrane was obtained in the same manner as in Example 1, except that the extraction conditions in Example 1 were adjusted so that the paraffin content of the microporous membrane obtained by the above measurement method was 2.0 wt%. Various physical properties of the obtained microporous membrane were measured by the methods described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com