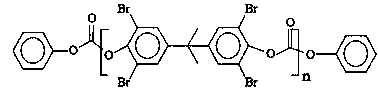

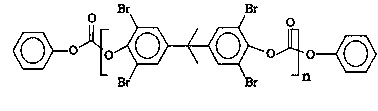

Method for preparing phenoxy tetrabromobisphenol A carbonate flame retardant

A technology of phenoxytetrabromobisphenol and tetrabromobisphenol, which is applied in the field of additive carbonate flame retardant preparation, can solve the problems of additive flame retardant use, general end-capping effect, and no end-capping, etc. Achieve full response, shorten reaction time, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Add 27.2 grams of tetrabromobisphenol A and 2.4 grams of phenol into 50 ml of dichloromethane, pass through cooling water, control the temperature at 20°C, and stir evenly to obtain a suspension or transparent liquid;

[0028] (2) Dissolve 7.0 grams of bis(trichloromethyl)carbonate in 20 milliliters of dichloromethane and stir evenly to obtain a chlorinated hydrocarbon solution of bis(trichloromethyl)carbonate for subsequent use;

[0029] (3) The temperature is controlled at normal temperature, and 0.9 g of triethylamine (3.3% of the mass of tetrabromobisphenol A) is added to the solution in step (2) under stirring;

[0030] (4) Add the solution obtained in step (1) to the solution obtained in step (2) at a constant speed. At the same time, add 5% sodium hydroxide solution dropwise to react until the reaction material is alkaline. After the addition is completed, keep warm for 2 hours ;

[0031] (5) After the heat preservation is over, stop stirring, let stand for ...

Embodiment 2

[0035] Under the same conditions as in Example 1, 1.0 g of pyridine (3.7% of tetrabromobisphenol A mass) was used instead of 0.9 g of triethylamine to obtain 30.5 g of phenoxytetrabromobisphenol A carbonate, and the technical detection indicators were as follows :

[0036] The number average molecular weight of the product is 2578, and the melting point is 190.8~197.2℃.

Embodiment 3

[0038] Under the same conditions as in Example 1, 0.9 gram of triethylamine was replaced with 1.3 gram of triethylbenzyl ammonium chloride (4.8% of tetrabromobisphenol A quality), and the obtained phenoxytetrabromobisphenol A carbonate 29.6 grams, the technical testing indicators are as follows:

[0039] The number average molecular weight of the product is 2498, and the melting point is 190.2~196.8℃.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com