Metal surface hardness easy-to-clean antibacterial shield and preparation method thereof

A technology for metal surfaces and antibacterial vehicles, applied in coatings, biocide-containing paints, antifouling/underwater coatings, etc., can solve environmental chemical pollution and other problems, achieve excellent electrical resistance, increase surface hardness, and bond powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

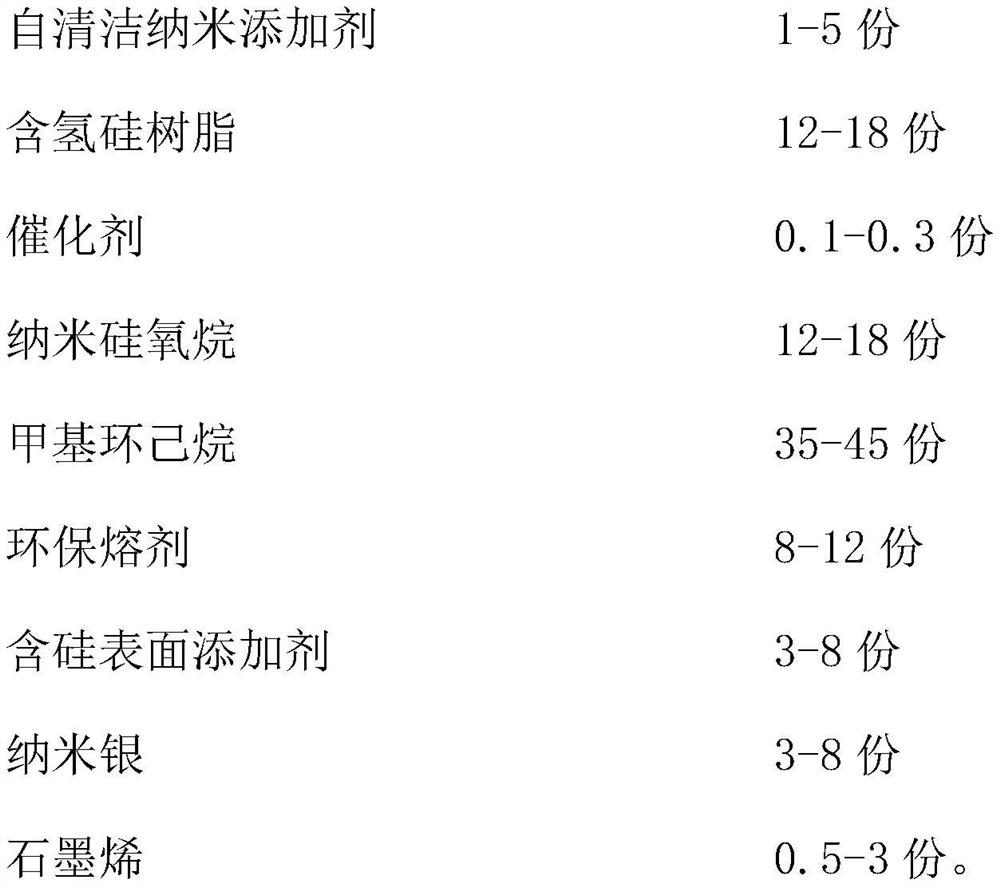

[0027] A metal surface hard and easy-to-clean antibacterial vehicle shield of the present invention and a preparation method thereof comprise the following raw materials in parts by weight:

[0028]

[0029] Among them, the self-cleaning nano-additive adopts TGA-2417 type self-cleaning nano-additive.

[0030] Among them, the hydrogen-containing silicone resin is any one of phenyl hydrogen-containing silicone resin, methyl hydrogen-containing MQ103 type silicone resin, and HMQ30 methyl hydrogen-containing silicone resin. This preferred embodiment uses phenyl hydrogen-containing silicone resin.

[0031] Wherein, the catalyst adopts trimethylaluminum.

[0032] Wherein, the environment-friendly solvent adopts any one in dimethyl carbonate, citric acid ester, ethylene glycol phenyl ether; this preferred embodiment adopts dimethyl carbonate.

[0033] Among them, the silicon-containing surface additive is BYK 3720 type.

[0034] A method for preparing a metal surface hardness an...

specific Embodiment 2

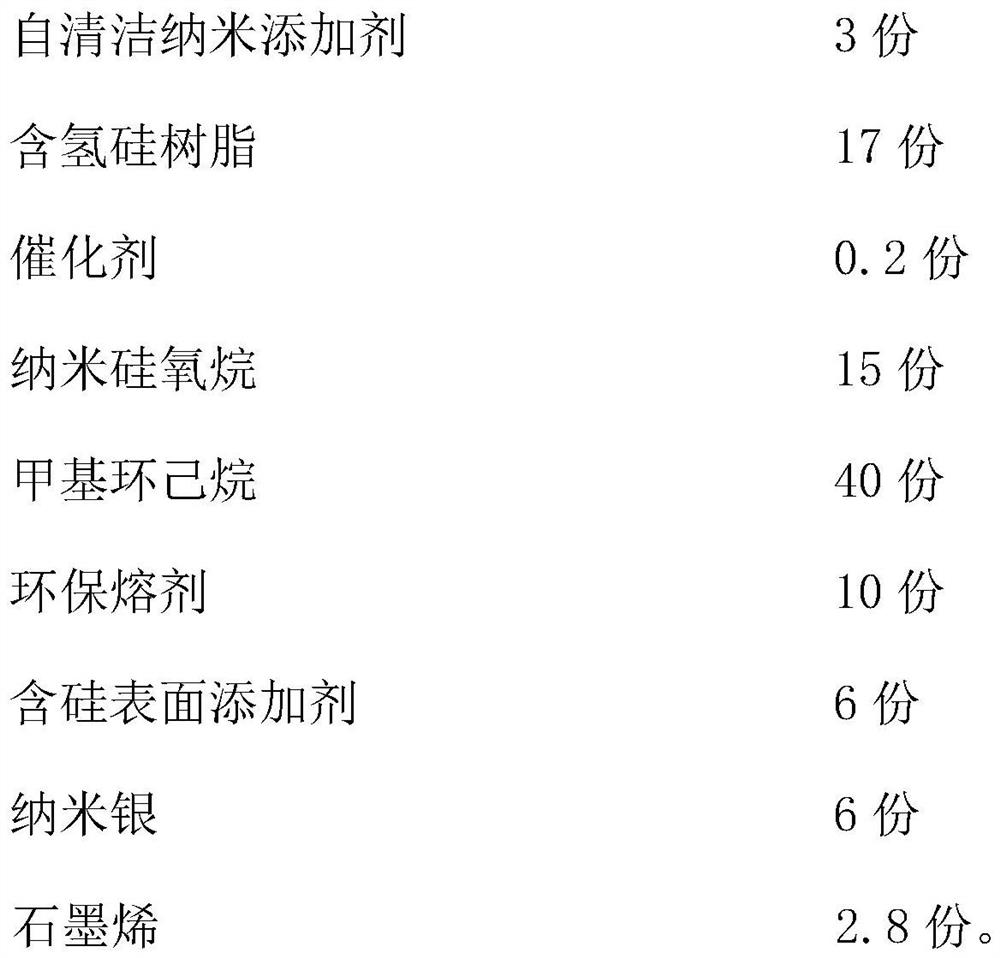

[0040] The difference between this preferred embodiment and specific embodiment 1 is that it includes the following raw materials in parts by weight:

[0041]

[0042]

[0043] Among them, the hydrogen-containing silicone resin in this preferred embodiment uses methyl hydrogen-containing MQ103 type silicone resin.

[0044] Wherein, the catalyst adopts trimethylaluminum.

[0045] Wherein, the present preferred embodiment of environment-friendly solvent adopts citric acid ester.

[0046] Among them, the silicon-containing surface additive is BYK 3720 type.

[0047] A method for preparing a metal surface hardness and easy-to-clean antibacterial car shield, comprising the following steps:

[0048] (1) Hydrogen-containing silicone resin modification: mix and stir the hydrogen-containing silicone resin, silicon-containing surface additives, nano-silver, catalyst, and graphene in the stated parts by weight, heat up to 75°C and react for 35 minutes, then cool naturally to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com