Silver nanowire anti-electromagnetic fabric and preparation method thereof

A silver nanowire, anti-electromagnetic technology, applied in plant fibers, textiles, papermaking, fiber types, etc., can solve the problems of poor process universality and uneven quality of anti-electromagnetic fabrics, and achieve performance stability and good anti-electricity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

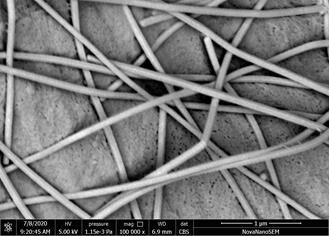

Image

Examples

Embodiment 1

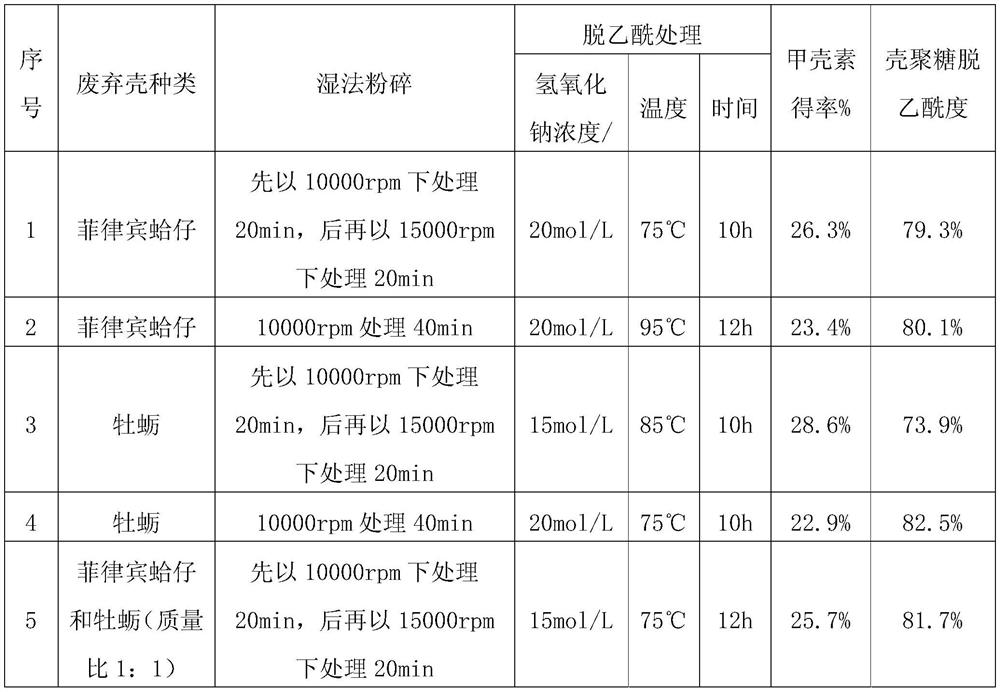

[0024] (1) Clean the discarded shells, freeze them at -30°C-40°C for 5 hours, then immerse them in water immediately, process them under 250W ultrasonic for 2 hours, and use a wet pulverizer to obtain shell slurry;

[0025] (2) Add trypsin at a weight ratio of 50:1 to discarded shells, heat to 35-37°C and stir for 20 minutes, add 75% citric acid to adjust the pH to 3-5, and stir at 60°C for 2-4 hours After that, place it in a water bath at a temperature of 100-120°C to inactivate the enzyme, centrifuge at 10,000 rpm to recover the supernatant, collect the precipitate, and use a mixed solution of ethanol and petroleum ether with a volume ratio of 2:1 to elute the precipitate multiple times. Add ethyl acetate to the eluted precipitate, place it in 250W ultrasonic wave for 30 minutes, recover ethyl acetate by rotary evaporation under reduced pressure, and obtain chitin after freeze-drying;

[0026] (3) Add chitin to a sufficient amount of sodium hydroxide solution for deacetylati...

Embodiment 2

[0030] (1) Cotton fabric pretreatment: cotton fabric is subjected to corona treatment, the voltage is 10kV, and the time is 15s;

[0031] (2) Preparation of silver nanowire solution: mix 10 g / L silver nanowire isopropanol dispersion solution with 1 g / L nitrosonium tetrafluoroborate ethanol solution at room temperature, and shake the mixture gently until the silver nanowire Precipitation, after centrifugation, redispersed in deionized water, added 100g / L aqueous solution of hydroxyl-terminated hyperbranched polymer (HPAE) at a volume ratio of 1:10, and stirred at a constant speed for 24 hours to obtain hydroxyl-terminated hyperbranched polymer-modified silver nanoparticles. Line, centrifuged, washed with deionized water and ethanol several times, dried and prepared into an aqueous solution of 100-4000mg / mL for later use;

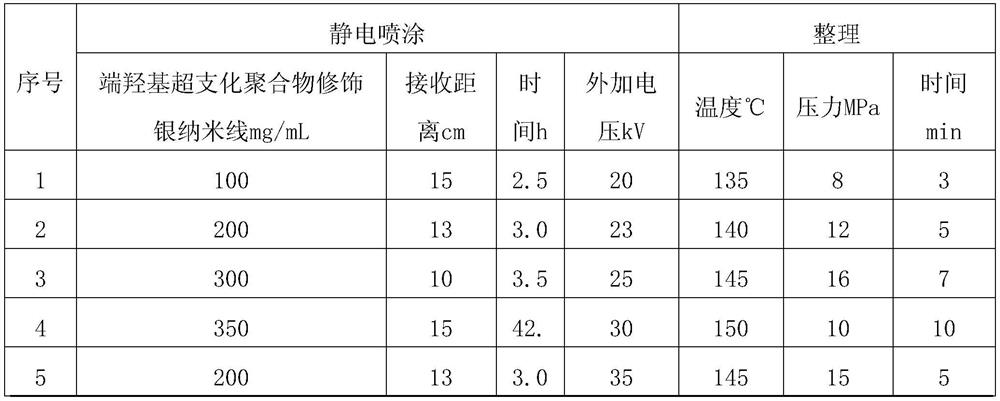

[0032] (3) Electrostatic spraying: alternately spraying and assembling the silver nanowires modified by the hydroxyl-terminated hyperbranched polymer and the...

Embodiment 3

[0037] (1) Pretreatment of polyester fabric: Corona treatment is performed on the polyester fabric, the voltage is 8`12kV, and the time is 10-20s, see Table 1;

[0038] Table 3 Fabric pretreatment and preparation methods of silver nanowires

[0039]

[0040] (2) Preparation of silver nanowire solution: mix 10 g / L silver nanowire isopropanol dispersion solution with 1 g / L nitrosonium tetrafluoroborate ethanol solution at room temperature, and shake the mixture gently until the silver nanowire Precipitate, after centrifugation, redisperse in deionized water, add 100g / L aqueous solution of hydroxyl-terminated hyperbranched polymer at a volume ratio of 1:10, stir at a constant speed for 24 hours, obtain hydroxyl-terminated hyperbranched polymer-modified silver nanowires, centrifuge Separate, wash with deionized water and ethanol several times, dry and prepare an aqueous solution of 100-4000 mg / mL for later use;

[0041] (3) The electrostatic spraying and finishing process is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com