Manufacturing method of positive electrode graphene

A manufacturing method, graphene technology, applied in chemical instruments and methods, battery electrodes, inorganic chemistry, etc., to achieve the effect of expanding the scope of application, easy access, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

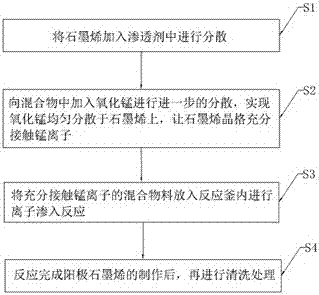

[0020] In order to express the present invention more clearly, the present invention will be further described below with reference to the accompanying drawings.

[0021] see figure 1 , a kind of manufacture method of anode graphene of the present invention, comprises following manufacture process:

[0022] S1. Penetrant dispersion: Add the 2D graphene material below four layers into the penetrant for dispersion, the penetrant is a non-ionic chelating agent (NH4) 4‧EDTA or (NH4) 4‧PTDA, the mixture of the penetrant and graphene The molar ratio is 2:1;

[0023] S2. Manganese ion dispersion: Manganese oxide is added to the mixture for further dispersion, so that manganese oxide is uniformly dispersed on the graphene, and the graphene lattice is fully contacted with manganese ions. The mixing molar ratio of manganese oxide and graphene is 1:1 ;

[0024] S3, manganese ion intercalation reaction: put the mixture material fully contacted with manganese ions into the reaction kett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com