Method for extracting salvia plebeia polysaccharides through supercritical CO2 fluid extraction technology

An extraction technology, the technology of lychee grass, is applied in the field of supercritical CO2 fluid extraction technology to extract polysaccharides from lychee grass, which can solve the problems of low extraction rate, destruction of polysaccharide molecular structure, and high cost, so as to achieve improved extraction rate, simple operation, and improved inhibition The effect of bacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

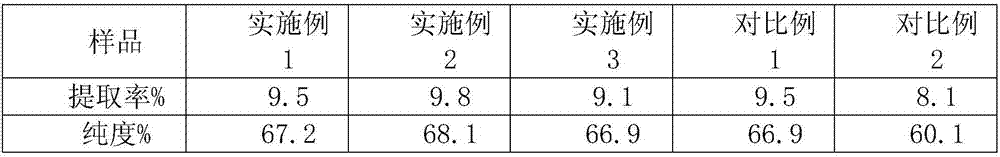

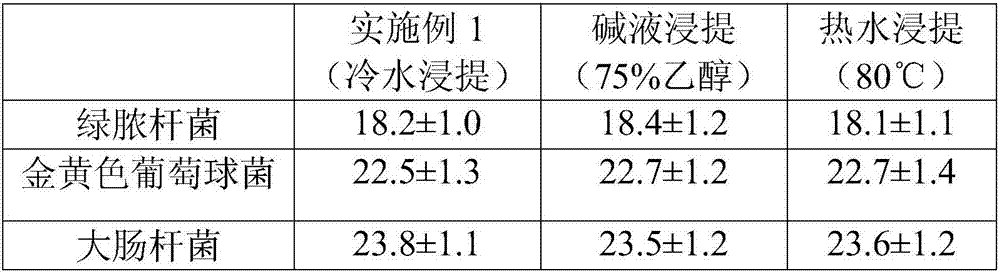

Examples

Embodiment 1

[0021] A supercritical CO 2 The method for extracting polysaccharides from lychee grass by fluid extraction technology comprises the following steps:

[0022] A. Wash the fresh leaves of lychee grass, remove impurities, and crush to obtain broken leaves after natural drying, with a particle size of ≤1mm;

[0023] B. Pour the crushed leaves into the sodium chloride solution and soak for 6 hours, take them out, dry them at room temperature and crush them again, the particle size is 0.5-5nm;

[0024] C. Using supercritical CO 2 The fluid is extracted, and the specific parameters are: pressure 25MPa, temperature 40°C, analytical pressure 3.5MPa, extraction time 2.5h;

[0025] D, the extracted lychee grass particles are finely pulverized, and the particle size is <0.5nm;

[0026] E. After cold water leaching, filter and carry out rotary evaporation at 55°C;

[0027] F, adopt 75% ethanol to carry out precipitation repeatedly;

[0028] G. The precipitate is vacuum-dried and then...

Embodiment 2

[0034] A supercritical CO 2 The method for extracting polysaccharides from lychee grass by fluid extraction technology comprises the following steps:

[0035] A. Wash the fresh leaves of lychee grass, remove impurities, and crush to obtain broken leaves after natural drying, with a particle size of ≤1mm;

[0036] B. Pour the crushed leaves into the sodium chloride solution and soak for 8 hours, take them out, dry them at room temperature and crush them again, the particle size is 0.5-5nm;

[0037] C. Using supercritical CO 2 The fluid is extracted, and the specific parameters are: pressure 20MPa, temperature 45°C, analytical pressure 3MPa, extraction time 4h;

[0038] D, the extracted lychee grass particles are finely pulverized, and the particle size is <0.5nm;

[0039] E. After cold water leaching, filter and perform rotary evaporation at 40°C;

[0040] F, adopt 80% ethanol to carry out precipitation repeatedly;

[0041] G. The precipitate is vacuum-dried and then pulve...

Embodiment 3

[0047] A supercritical CO 2 The method for extracting polysaccharides from lychee grass by fluid extraction technology comprises the following steps:

[0048] A. Wash the fresh leaves of lychee grass, remove impurities, and crush to obtain broken leaves after natural drying, with a particle size of ≤1mm;

[0049] B. Pour the crushed leaves into the sodium chloride solution and soak for 4 hours, take them out, dry them at room temperature and crush them again, the particle size is 0.5-5nm;

[0050] C. Using supercritical CO 2 The fluid is extracted, and the specific parameters are: pressure 30MPa, temperature 30°C, analytical pressure 5MPa, extraction time 1h;

[0051] D, the extracted lychee grass particles are finely pulverized, and the particle size is <0.5nm;

[0052] E. After cold water leaching, filter and perform rotary evaporation at 60°C;

[0053] F, adopt 70% ethanol to carry out precipitation repeatedly;

[0054] G. The precipitate is vacuum-dried and then pulve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com