Preparation method of graphene and polyester fibers

A polyester fiber and graphene technology, applied in the fiber field, can solve the problems of complex production process, high price, complicated equipment, etc., and achieve the effects of widening the scope of use, reducing production costs, and improving mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

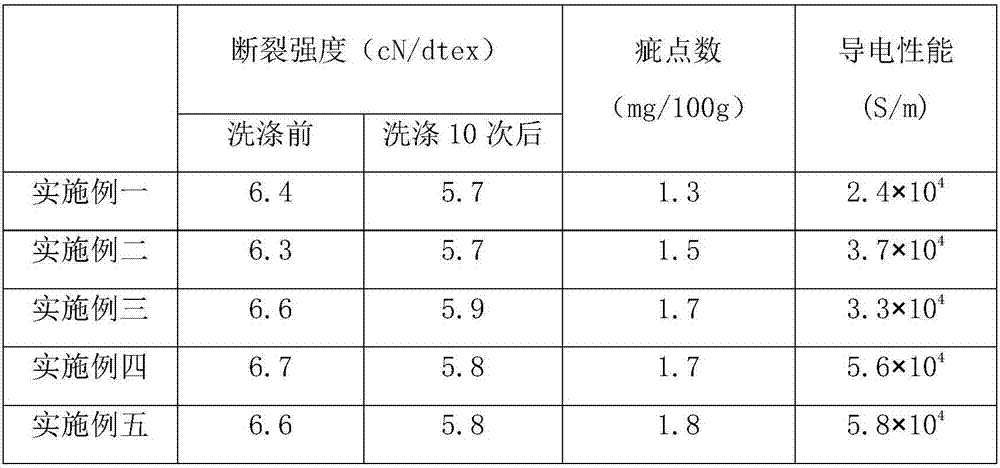

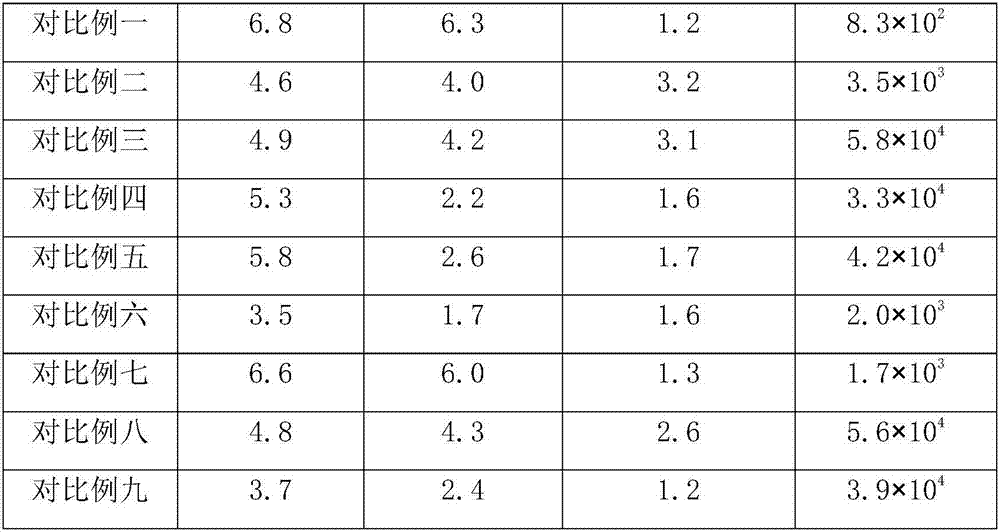

Examples

Embodiment 1

[0033] The present embodiment provides a kind of preparation method of graphene polyester fiber, and its preparation process is as follows:

[0034] (1) Preparation of graphene polyester masterbatch

[0035] Put terephthalic acid and ethylene glycol into the reactor at a weight ratio of 1:1, and add 0.03wt% catalyst ethylene glycol antimony and 0.001wt% graphene at the same time. The whole process is carried out under nitrogen protection. Set The nitrogen pressure is 0.3MPa, the stirring speed is 70r / min, and the esterification temperature is 240°C. After the esterification starts, wait until the amount of water evaporated reaches 85% of the theoretical value, release the pressure to normal pressure, and the esterification is completed; set The polycondensation temperature is 250°C, and the polycondensation time is 150min. After the polycondensation is completed, the material is discharged and pelletized.

[0036] (2) Melt spinning

[0037] Weigh 1g of polymer particles each...

Embodiment 2

[0039]The present embodiment provides a kind of preparation method of graphene polyester fiber, and its preparation process is as follows:

[0040] (1) Preparation of graphene polyester masterbatch

[0041] Put terephthalic acid and ethylene glycol into the reactor at a weight ratio of 1:1.2, and add 0.04wt% catalyst ethylene glycol antimony and 0.01wt% graphene at the same time. The whole process is carried out under nitrogen protection. Set The nitrogen pressure is 0.4MPa, the stirring speed is 80r / min, and the esterification temperature is 260°C. After the esterification starts, wait until the amount of water evaporated reaches 90% of the theoretical value, release the pressure to normal pressure, and the esterification is completed; set The polycondensation temperature is 260°C, and the polycondensation time is 180min. After the polycondensation is completed, the material is discharged and pelletized.

[0042] (2) Melt spinning

[0043] Weigh 1g of polymer particles each...

Embodiment 3

[0045] The present embodiment provides a kind of preparation method of graphene polyester fiber, and its preparation process is as follows:

[0046] (1) Preparation of graphene polyester masterbatch

[0047] Put terephthalic acid and ethylene glycol into the reactor at a weight ratio of 1:1.5, and add 0.03wt% catalyst antimony acetate and 0.1wt% graphene at the same time. The whole process is carried out under the protection of nitrogen. The pressure is 0.2MPa, the stirring speed is 60r / min, and the esterification temperature is 280°C. After the esterification starts, wait until the amount of water evaporated reaches 90% of the theoretical value, release the pressure to normal pressure, and the esterification ends; set polycondensation The temperature is 270°C, and the polycondensation time is 200 minutes. After the polycondensation is completed, the material is discharged and pelletized.

[0048] (2) Melt spinning

[0049] Weigh 1g of polymer particles each time, add them t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com