Novel insulation and waterproof thermal shrinkage terminal

A terminal heat-shrinking technology, which is applied in the direction of connection insulation, contact box/base manufacturing, contact assembly/disassembly, etc., can solve the problems of automobile short circuit, no waterproof insulation function, difficult operation, etc., and achieve insulation performance and Good wear resistance, better comprehensive performance, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

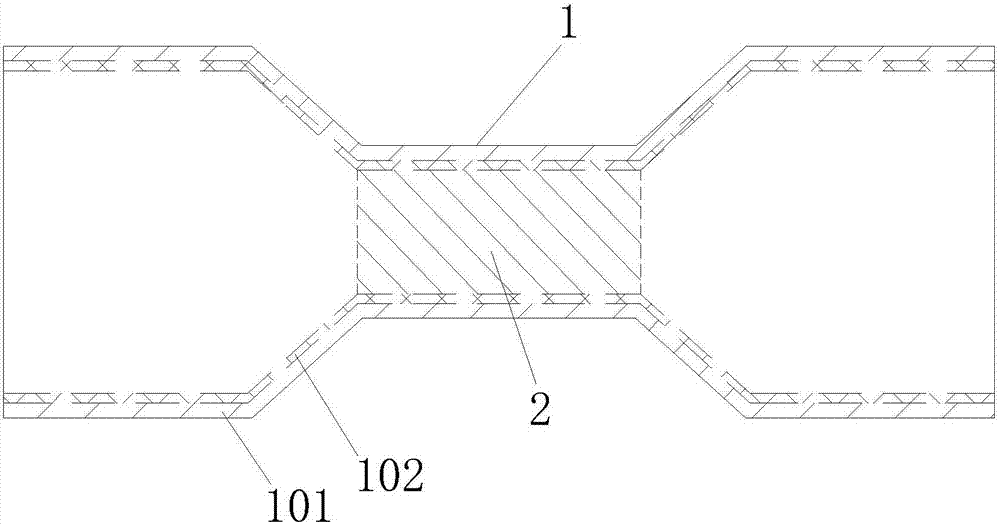

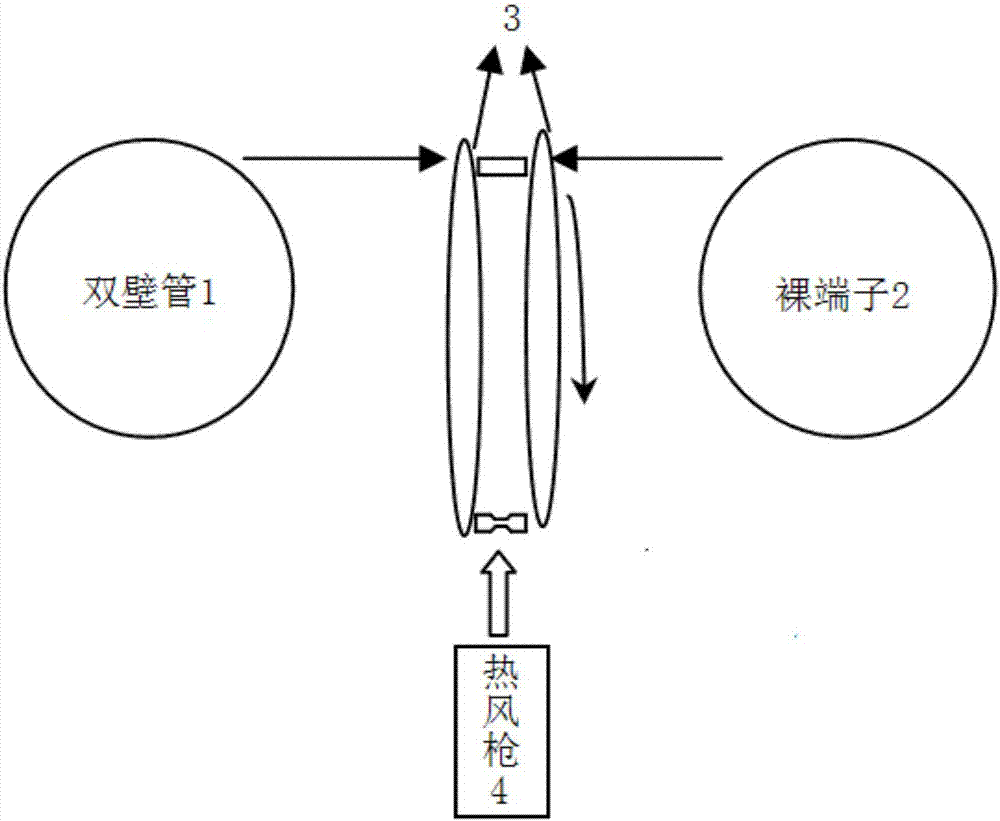

[0031] Example 1: The preparation method of the heat-shrinkable terminal is as follows: (1) Preparation of double-wall pipe: ① Add high-density polyethylene (outer wall layer material) and ethylene-vinyl acetate copolymer (inner wall layer material) to the main extruder respectively And in the side extruder, the processing temperature of the main extruder is 150-180°C, and the processing temperature of the side extruder is 80-140°C, extruded, then cooled and dried to obtain a semi-finished double-wall heat-shrinkable tube;

[0032] ②Irradiation: Put the semi-finished double-wall heat-shrinkable tube prepared in step ① on the pay-off frame, and introduce it into the irradiation room through the tension frame, and cyclically irradiate and cool the semi-finished double-wall heat-shrinkable tube. 13 Mrad;

[0033] ③ Expansion: After heating, expanding and cooling the magnetically conductive double-wall heat-shrinkable tube irradiated in step ②, the finished double-wall heat-shrink...

Embodiment 2

[0036] Embodiment 2: The preparation method of the heat-shrinkable terminal is: (1) Preparation of a double-walled tube: ① Add sarin resin (outer wall layer material) and ethylene-vinyl acetate copolymer (inner wall layer material) into the main extruder and the In the side extruder, the processing temperature of the main extruder is 150-180°C, and the processing temperature of the side extruder is 80-140°C, extruded, then cooled and dried to obtain a semi-finished double-wall heat-shrinkable tube;

[0037] ②Irradiation: Put the semi-finished double-wall heat-shrinkable tube prepared in step ① on the pay-off frame, and introduce it into the irradiation room through the tension frame, and cyclically irradiate and cool the semi-finished double-wall heat-shrinkable tube. 13 Mrad;

[0038] ③ Expansion: After heating, expanding and cooling the magnetically conductive double-wall heat-shrinkable tube irradiated in step ②, the finished double-wall heat-shrinkable tube is produced. Th...

Embodiment 3

[0041] Example 3: The preparation method of the heat-shrinkable terminal is: (1) Preparation of double-walled tube: ①Add ethylene-acrylic acid copolymer (outer wall layer material) and ethylene-acrylic acid copolymer (inner wall layer material) to the main extruder respectively And in the side extruder, the processing temperature of the main extruder is 150-180°C, and the processing temperature of the side extruder is 80-140°C, extruded, then cooled and dried to obtain a semi-finished double-wall heat-shrinkable tube;

[0042]②Irradiation: Put the semi-finished double-wall heat-shrinkable tube prepared in step ① on the pay-off frame, and introduce it into the irradiation room through the tension frame, and cyclically irradiate and cool the semi-finished double-wall heat-shrinkable tube. 13 Mrad;

[0043] ③Expansion: After heating, expanding and cooling the magnetically conductive double-wall heat-shrinkable tube irradiated in step ②, the finished double-wall heat-shrinkable tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com