Granulated soybean protein and preparation method thereof

A soybean protein and granulation technology, which is applied in the field of soybean protein, can solve the problems of inapplicability of granulated soybean protein, and achieve the effects of improving application value, concentrated particle size distribution, and high protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Dissolve 10g of soybean protein isolate in 100ml of deionized water, stir at room temperature for 1 hour, and adjust the pH to 5.5.

[0043] (2) The protein solution obtained in step (1) was placed in a 90°C water bath and stirred at a speed of 400r / min for 60min, and then dispersed in an ice-water bath at a speed of 8000r / min for 1min.

[0044] (3) The protein solution obtained in step (3) was subjected to high-pressure micro-jet homogenization at a pressure of 20 MPa, and the number of homogenization was 2 times. Finally, spray drying is carried out to obtain granulated soybean protein products.

[0045] The above spray drying conditions are that the inlet temperature is set at 160° C., the outlet temperature is 90° C., and the injection flow rate is 4.5 ml / min.

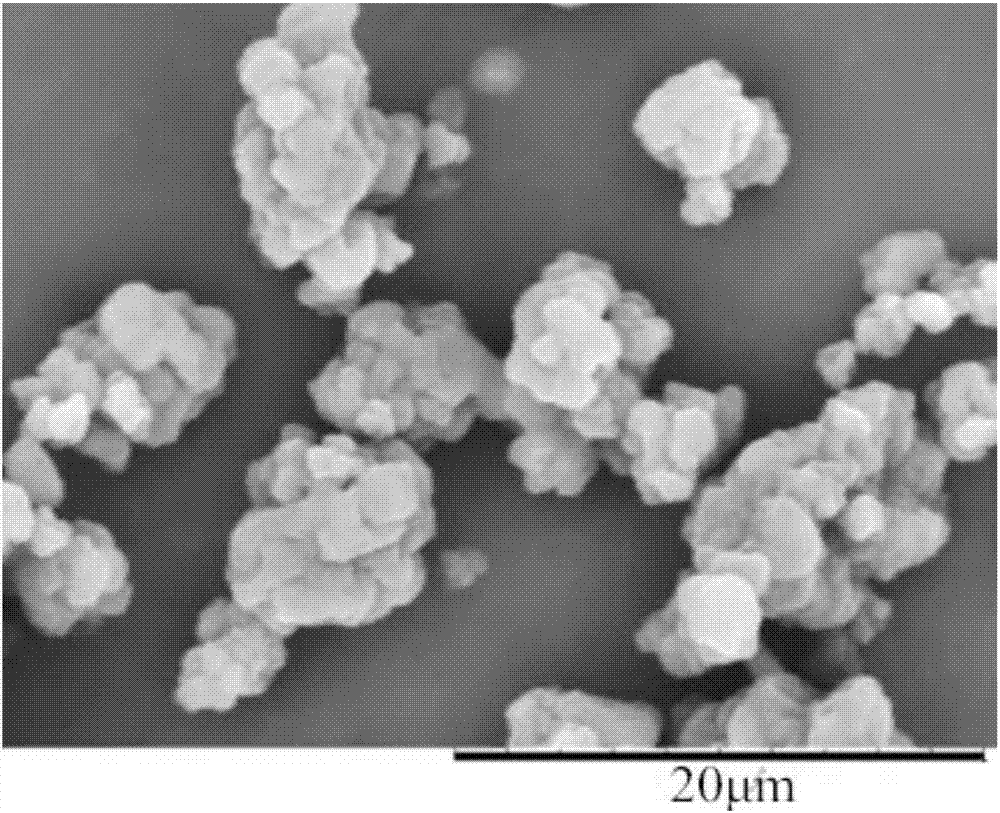

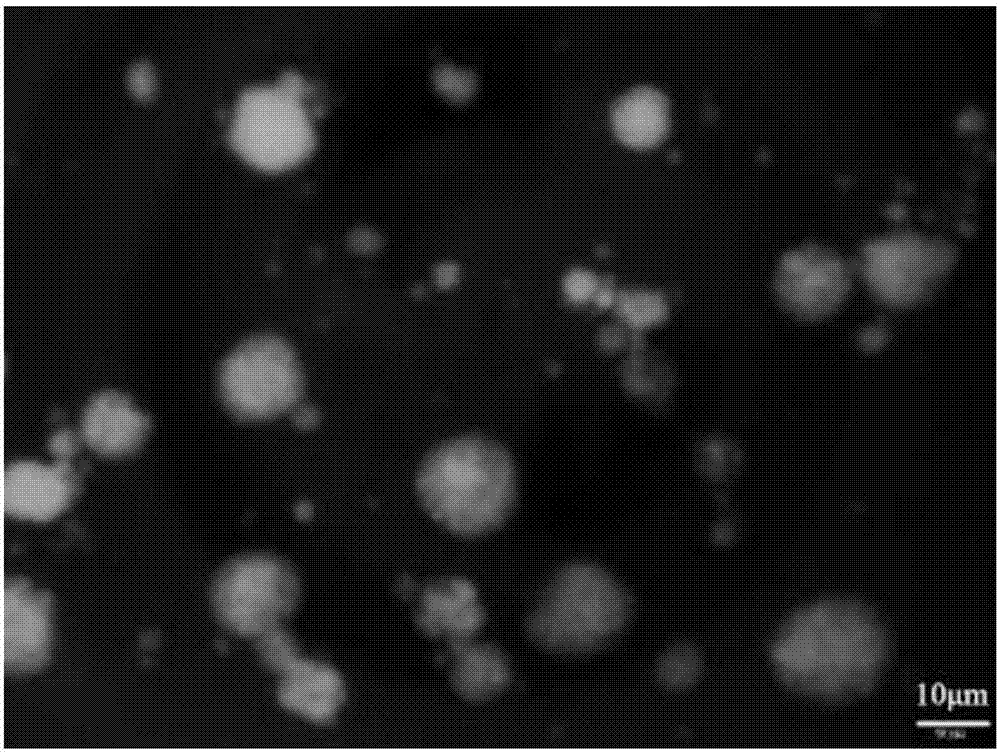

[0046] The granulated soybean protein powder obtained in this example is solid irregular spherical, and its particle size is about 10 μm (see Figure 1a ); the morphology of particles in water after ful...

Embodiment 2

[0048] (1) Dissolve 30g soybean protein isolate in 200ml deionized water, stir at room temperature for 2 hours, and adjust the pH to 5.5.

[0049] (2) The protein solution obtained in step (1) was placed in a 95°C water bath and stirred at a speed of 700r / min for 5min, and then dispersed in an ice-water bath at a speed of 12000r / min for 3min.

[0050] (3) Repeat the process of step (2) for the protein solution obtained in step (2) twice.

[0051] (4) Disperse the protein solution obtained in step (3) at a high speed of 12,000r / min for 2 minutes, and then perform high-pressure micro-jet homogenization at a pressure of 50MPa for 3 times. Finally, spray drying is carried out to obtain granulated soybean protein products.

[0052] The spray drying conditions were as follows: the inlet temperature was set to 180°C, the outlet temperature was set to 100°C, and the injection flow rate was 3.0ml / min.

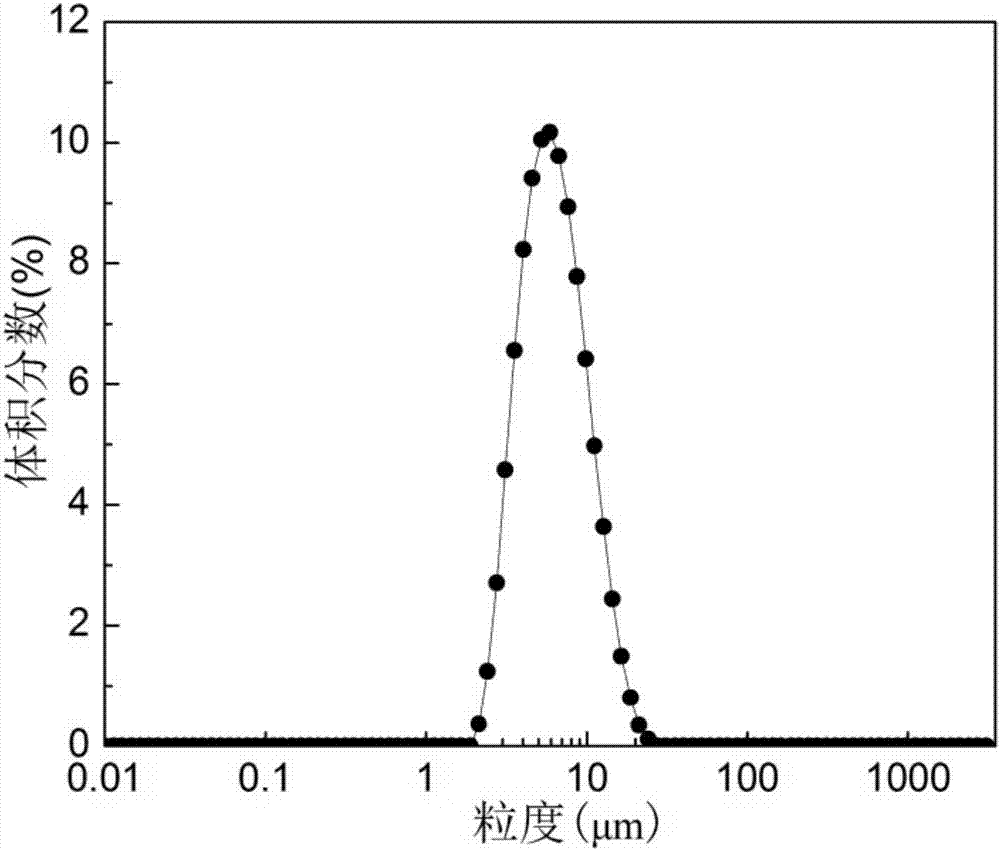

[0053] The particle size of the granulated soybean protein obtained in this examp...

Embodiment 3

[0055] (1) Dissolve 20g of soybean protein isolate in 100ml of deionized water, stir at room temperature for 3 hours, and adjust the pH to 3.8.

[0056] (2) Put the protein solution obtained in step (1) in a water bath environment at 100°C and stir at a speed of 1000r / min for 30min, then stir and cool at room temperature at a speed of 1000r / min to room temperature.

[0057] (3) Repeat the process of step (2) for 4 times with the protein dispersion obtained in step (2).

[0058] (4) Disperse the dispersion liquid obtained in step (3) at a speed of 15000r / min for 3 minutes, and then perform high-pressure micro-jet homogenization at a pressure of 80 MPa, and the number of homogenization is 4 times. Finally, spray drying is carried out to obtain granulated soybean protein products.

[0059] The spray drying conditions were as follows: the inlet temperature was set to 200°C, the outlet temperature was set to 110°C, and the injection flow rate was 1.5ml / min.

[0060] The particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com