A macroporous alumina-based catalyst suitable for pressurized sulfur recovery process and its preparation method

A macroporous alumina and catalyst technology, applied in the direction of sulfur preparation/purification, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of deactivation and blocked pores, and achieve Effects of long service life, enlarged pore size, and good Claus reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

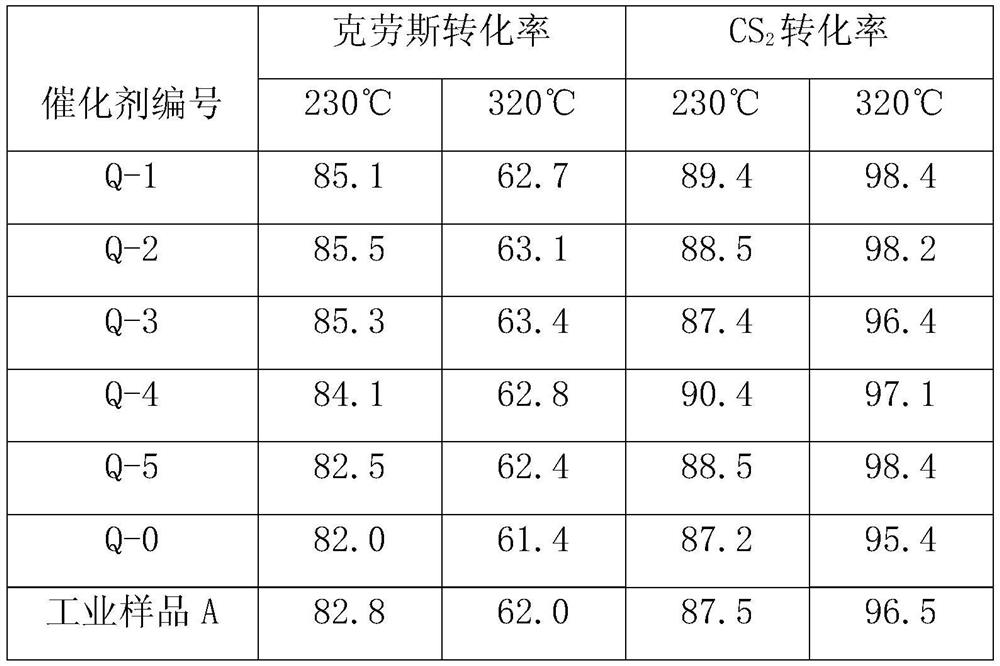

[0016] Weigh pseudo-boehmite 100g, magnesium aluminum spinel (MgAl 2 o 4 ) powder 10g, squat powder 5g, and starch 5g were uniformly mixed, mixed with 3% nitric acid solution, rolled into balls, and calcined at 550°C for 3h to obtain a catalyst. The catalyst number was Q-1. The chemical composition of the catalyst is: Al 2 o 3 87.5%, MgAl 2 o 4 12.5%, the strength, specific surface area and average pore diameter data of the catalyst are shown in Table 1, and the activity evaluation is shown in Table 2.

Embodiment 2

[0018] Weigh pseudo-boehmite 100g, MgAl 2 o 4 Mix 20g of powder, 10g of turnip powder, and 10g of cellulose evenly, mix with 3% nitric acid solution, roll into balls, and roast at 550°C for 3h to prepare the catalyst. The catalyst number is Q-2. The chemical composition of the catalyst is: Al 2 o 3 77.8%, MgAl 2 o 4 22.2%, the strength, specific surface area and average pore diameter data of the catalyst are shown in Table 1, and the activity evaluation is shown in Table 2.

Embodiment 3

[0020] Weigh pseudo-boehmite 100g, MgAl 2 o 4 Powder 5g, γ-Al 2 o 3 Mix 10 g and 10 g of scallop powder evenly, mix with 3% nitric acid solution + 5% polyvinyl alcohol aqueous solution, roll into a ball, and roast at 550°C for 3 hours to obtain a catalyst. The catalyst number is Q-3. The chemical composition of the catalyst is: Al 2 o 3 94.1%, MgAl 2 o 4 5.9%, the strength, specific surface area, average pore diameter and other data of the catalyst are shown in Table 1, and the activity evaluation is shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com