A compound restoration agent for cleaning oil-contaminated soil

A technology of oil pollution and remediation agent, applied in the field of environmental remediation, can solve the problems of high cost, high technical requirements, and long effective period, and achieve low cost, low technical requirements, and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

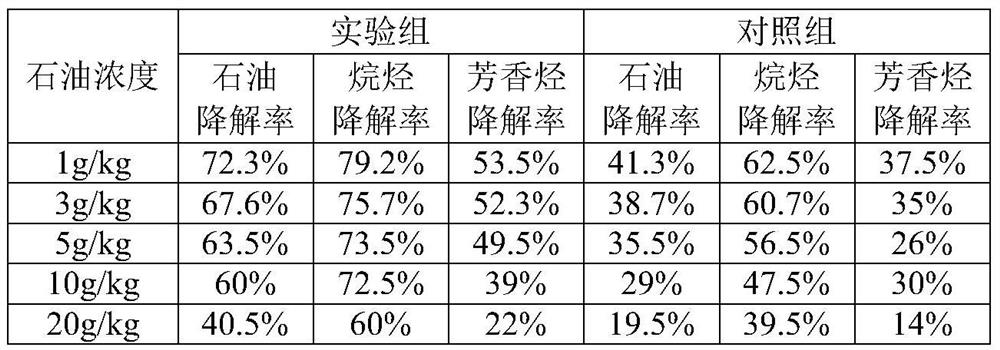

Examples

Embodiment 1

[0022] A compound restoration agent for cleaning oil-contaminated soil, which is prepared from 200g of plant enzyme and 100g of biochar, wherein the biochar is calcined by kelp in an oxygen-isolated environment, and the plant enzyme is prepared from 100g of discarded vegetable leaves, rice 20g, 150g of rice washing water, 50g of brown sugar, and 2g of cellulase are fermented, and the fermentation temperature of the preferred plant enzyme is 20°C, and the fermentation time is 30 days. The preferred preparation process of the Youfu compound repair agent is as follows: add biochar to the plant enzyme fermented for 2 days to continue fermentation, filter through a 100-mesh sieve after the fermentation is completed, and then sterilize the obtained mixture in an ultraviolet environment to obtain the repair product. With repair agent.

[0023] The preparation process of biochar includes the following steps:

[0024] (1) Wash the surface of the kelp and soak it in deionized water for...

Embodiment 2

[0028] A compound restoration agent for cleaning oil-contaminated soil, which is prepared from 350g of plant enzyme and 100g of biochar, wherein the biochar is calcined by kelp in an oxygen-isolated environment, and the plant enzyme is prepared from 100g of discarded vegetable leaves, rice 25g, 175g of rice washing water, 65g of brown sugar, and 3.5g of cellulase are fermented, and the fermentation temperature of the preferred plant enzyme is 25°C, and the fermentation time is 20 days. The preferred preparation process of the Youfu compound repair agent is as follows: add biochar to the plant enzyme fermented for 2 days to continue fermentation, filter through a 110-mesh sieve after the fermentation is completed, and then sterilize the resulting mixture in an ultraviolet environment to obtain the repair product. With repair agent.

[0029] The preparation process of biochar includes the following steps:

[0030] (1) Wash the surface of the kelp and soak it in deionized water ...

Embodiment 3

[0034] A compound restoration agent for cleaning oil-contaminated soil, which is prepared from 500g of plant enzyme and 100g of biochar, wherein the biochar is calcined by kelp in an oxygen-isolated environment, and the plant enzyme is prepared from 100g of discarded vegetable leaves, rice 30g, 200g of rice washing water, 80g of brown sugar, and 5g of cellulase are fermented. The fermentation temperature of the preferred plant enzyme is 30°C and the fermentation time is 7 days. The preferred preparation process of the Youfu compound repair agent is as follows: add biochar to the plant enzyme fermented for 3 days to continue fermentation, filter through a 120-mesh sieve after the fermentation is completed, and then put the resulting mixture in an ultraviolet environment to sterilize to obtain the repair product. With repair agent.

[0035] The preparation process of biochar includes the following steps:

[0036] (1) Wash the surface of the kelp and soak it in deionized water f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com