Printing and dyeing wastewater treating agent and preparation method thereof

A technology for printing and dyeing wastewater and treatment agent, which is used in water treatment parameter control, textile industry wastewater treatment, water/sewage treatment, etc. , to achieve the effect of strong practicability, solving environmental problems, and high-efficiency purification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The raw material components of a printing and dyeing wastewater treatment agent include: 60 parts of construction waste, 22 parts of soybean powder, 18 parts of wheat straw powder, 13 parts of kaolin, 10 parts of muddy soil, 15 parts of peat, waste paper scraps (maximum length less than 2mm ) 20 parts, clay 22 parts, aluminum chloride 18 parts, polyferric sulfate 10 parts, polysilicate flocculant (PSAA) 7 parts, polyphosphorus aluminum chloride (PPAC) 13 parts, flocculant PF1018 parts and water 100 parts , the parts are parts by mass.

[0027] The preparation method of above-mentioned printing and dyeing wastewater treatment agent comprises the steps:

[0028] 1) Pulverize the construction waste to a particle size of less than 1 mm to obtain construction waste powder;

[0029] 2) Heat up the construction waste powder obtained in step 1) to 200°C at a speed of 12°C / min, keep it warm for 33 minutes, then raise the temperature to 400°C at a speed of 38°C / min, keep it warm...

Embodiment 2

[0033] Basically the same as Example 1, the difference is: a printing and dyeing wastewater treatment agent, its raw material components include: 55 parts of construction waste, 20 parts of soybean powder, 15 parts of wheat straw powder, 10 parts of kaolin, and 8 parts of muddy soil , 12 parts of peat, 18 parts of waste paper (maximum length less than 2mm), 20 parts of clay, 15 parts of aluminum chloride, 8 parts of polyferric sulfate, 5 parts of polysilicate flocculant (PSAA), polyphosphorus aluminum chloride ( 10 parts of PPAC), 5 parts of flocculant PF101 and 100 parts of water, the parts are parts by mass.

Embodiment 3

[0035] Basically the same as Example 1, the difference is: a printing and dyeing wastewater treatment agent, its raw material components include: 65 parts of construction waste, 25 parts of soybean powder, 20 parts of wheat straw powder, 15 parts of kaolin, 13 parts of muddy soil , 18 parts of peat, 23 parts of waste paper (maximum length less than 2mm), 25 parts of clay, 20 parts of aluminum chloride, 13 parts of polyferric sulfate, 8 parts of polysilicate flocculant (PSAA), polyphosphorus aluminum chloride ( 15 parts of PPAC), 10 parts of flocculant PF101 and 100 parts of water, the parts are parts by mass.

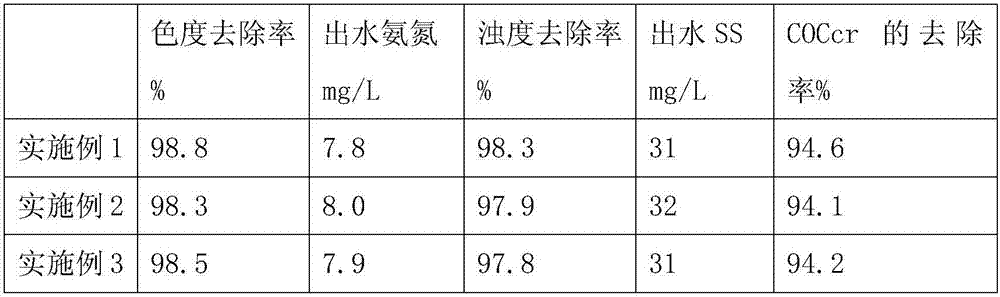

[0036] Table 1 is the performance table of each embodiment gained product

[0037]

[0038] In each example, the usage amount of printing and dyeing wastewater purification agent is 0.5% of the wastewater quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com