Method for processing rare earth ore concentrate

A rare earth concentrate and mixed treatment technology, which is applied in the direction of improving process efficiency, can solve problems such as difficult continuous dynamic production, and achieve the effects of avoiding radioactive hazards, avoiding decomposition, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

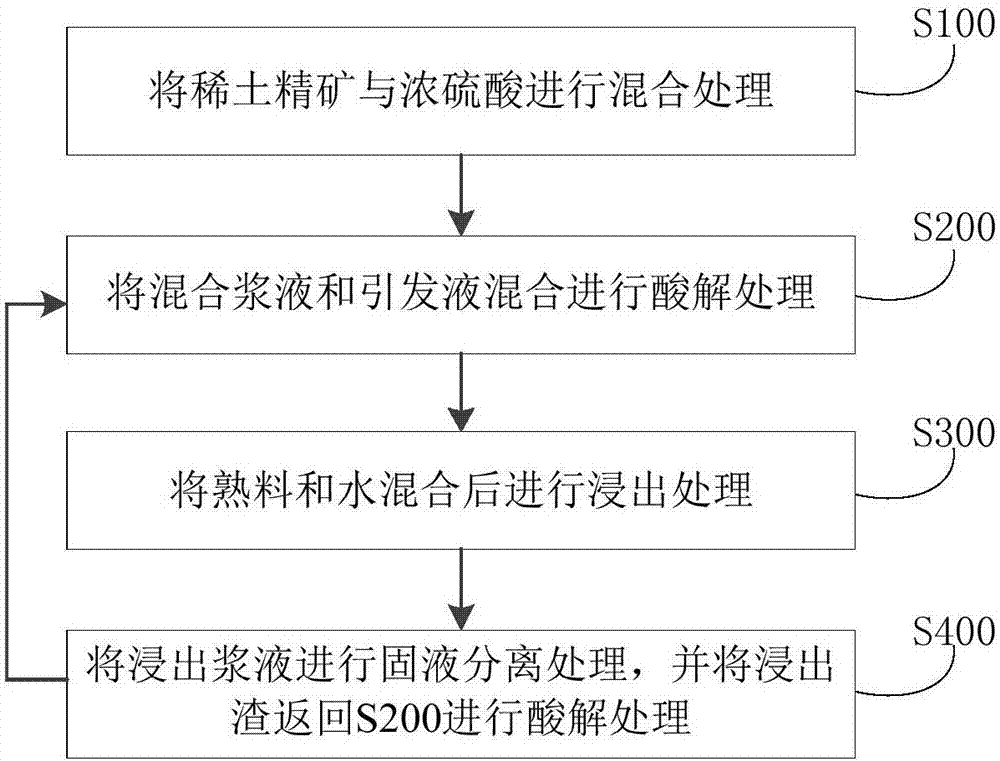

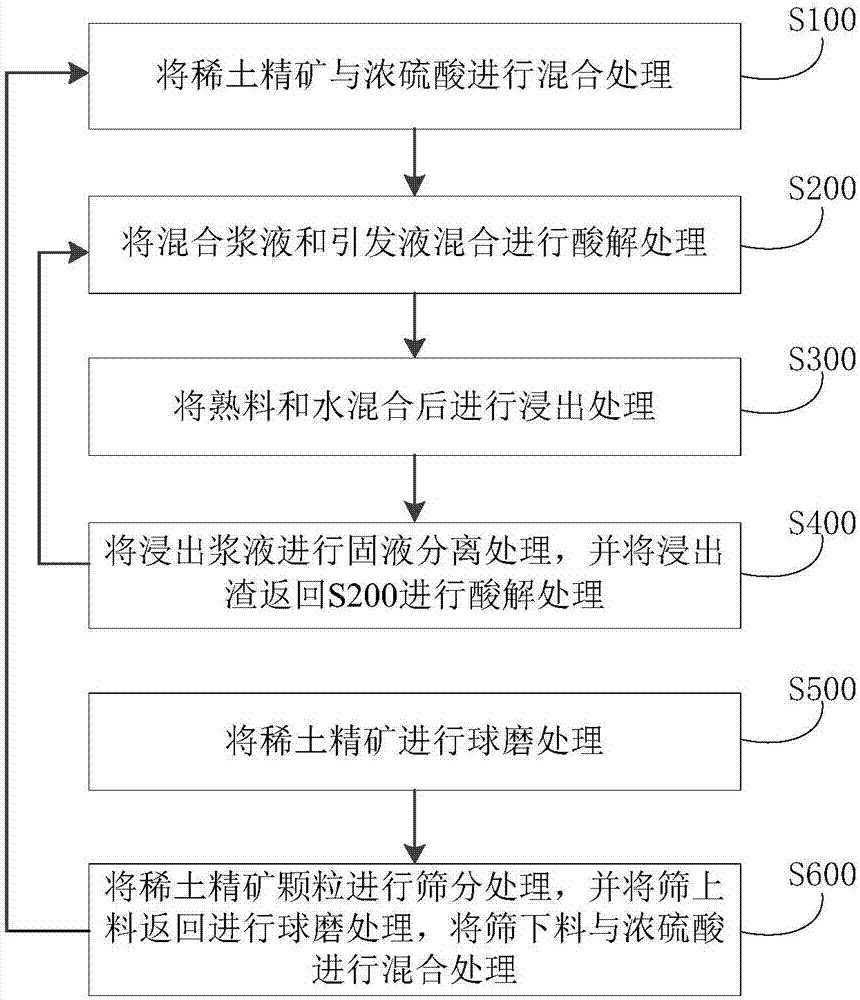

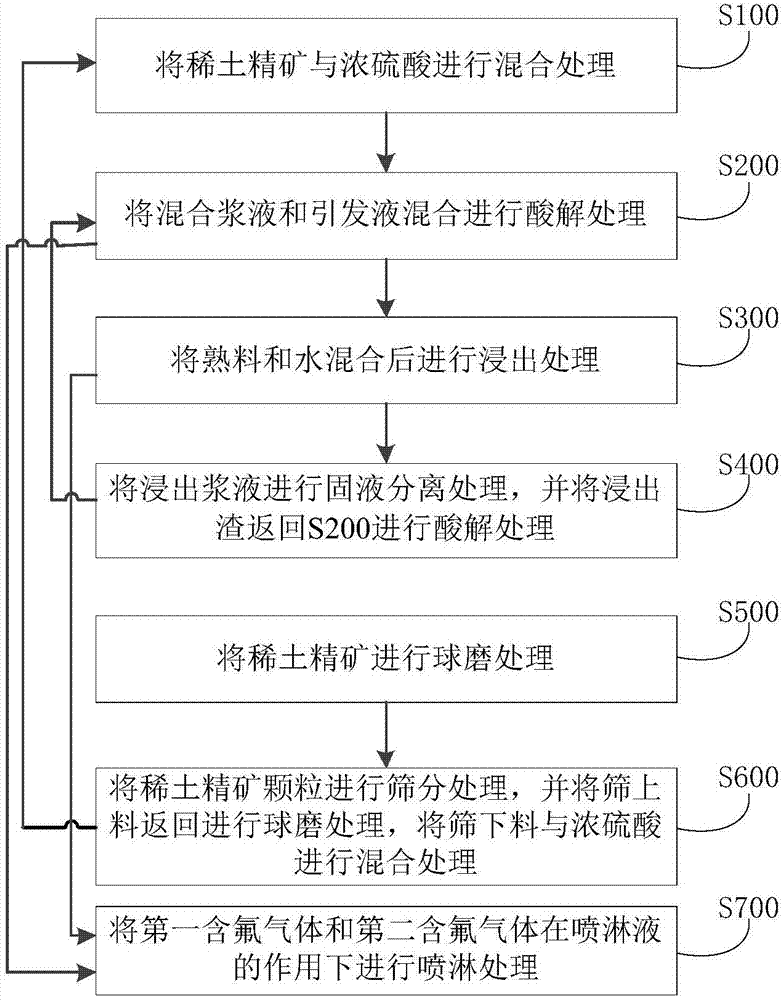

Method used

Image

Examples

Embodiment 1

[0109] The bastnaesite rare earth ore is ball milled by a ball mill and sieved by a screening device to obtain bastnaesite rare earth concentrate particles with a particle size of 80-320 mesh; the bastnaesite rare earth concentrate is measured and put into the pre-measured In the mixing device containing 98wt% concentrated sulfuric acid, the mass ratio of concentrated sulfuric acid to bastnaesium rare earth concentrate particles is 1.4:1, the circulating cooling water of the mixing device is turned on, and the temperature in the mixing device is controlled to be less than 30 degrees Celsius, Stir fully for 10 minutes to form a uniform mixed slurry mixed with acid, and at the same time generate the first fluorine-containing gas; then discharge the mixed slurry through the mixed slurry outlet of the mixing device, add it to the acid hydrolysis device, and open the trigger solution (industrial water) to enter the liquid The valve dilutes the concentrated sulfuric acid in the mixed...

Embodiment 2

[0112] The bastnaesite rare earth ore is ball milled by a ball mill and screened by a screening device to obtain bastnaesite rare earth concentrate particles with a particle size of 80-320 mesh; the bastnaesite rare earth concentrate particles are measured and placed in a pre-measured container In the mixing device with 98wt% concentrated sulfuric acid, the mass ratio of concentrated sulfuric acid to bastnaesin rare earth concentrate particles is 1.5:1, the circulating cooling water of the mixing device is turned on, and the temperature in the mixing device is controlled to be less than 30 degrees Celsius, fully Stir for 8 minutes to form a uniform mixed slurry mixed with acid, and generate the first fluorine-containing gas at the same time; then discharge the mixed slurry through the mixed slurry outlet of the mixing device, add it to the acid hydrolysis device, and open the trigger liquid (waste acid) inlet valve , dilute the concentrated sulfuric acid in the mixed slurry, re...

Embodiment 3

[0115] Put the mixed ore containing bastnaesite rare earth and monazite with a particle size of 80-320 mesh into the mixing device that has been measured in advance and contains 98wt% concentrated sulfuric acid. The mass ratio of concentrated sulfuric acid to mixed ore is 1.5 : 1. Turn on the circulating cooling water of the mixing device, control the temperature in the mixing device to be less than 30 degrees Celsius, and fully stir for 10 minutes to form a mixed slurry evenly mixed with acid, and generate the first fluorine-containing gas at the same time; then mix the mixed slurry through mixing The mixed slurry outlet of the device is discharged, added to the acidolysis unit, the inlet valve of the trigger solution (mixed solution containing industrial water and waste acid) is opened, the concentrated sulfuric acid in the mixed slurry is diluted, heat is released, and the acidolysis unit is assisted Heating device, adjust the temperature in the acidolysis device, stir at 85...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com