Method for renewing copper-electrolysis conducting rod at low cost

A technology for electrolytic conduction and conductive rods, which is applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of waste of resources, weakened electrical conductivity, and high strength of conductive rods, so as to achieve recycling, enhanced electrical conductivity, and scientific methods. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

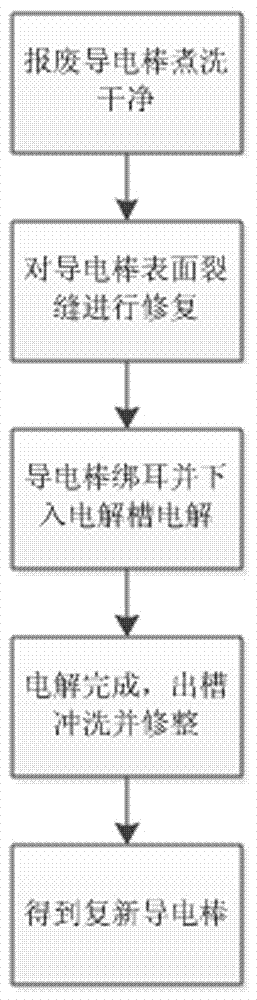

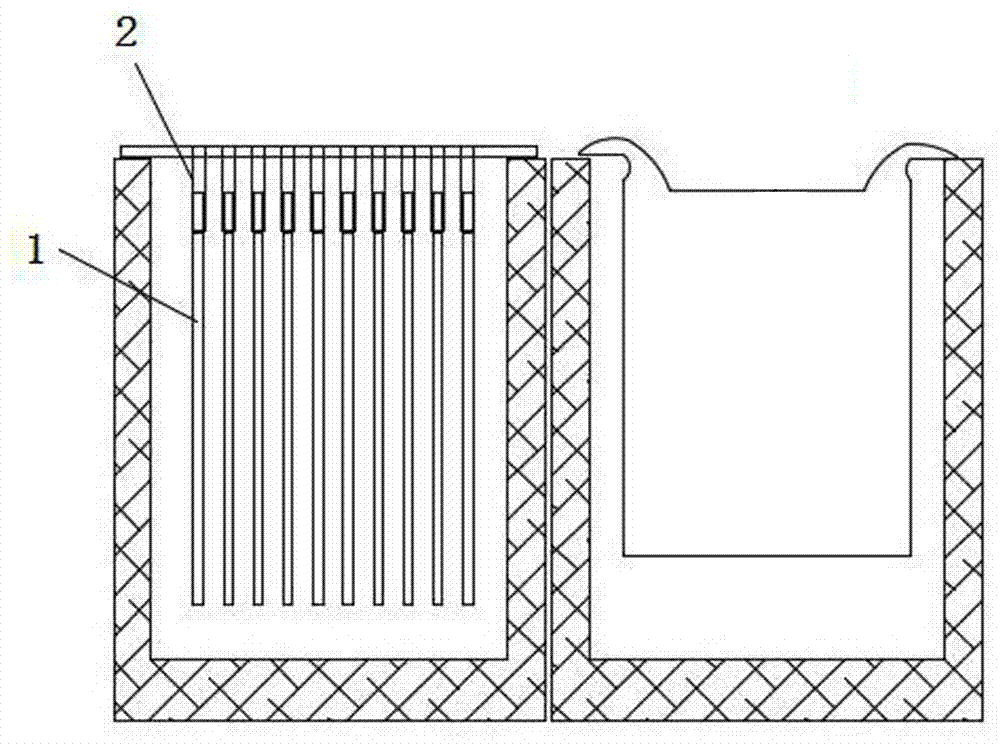

[0041] Taking the scrapped conductive rods in the copper electrolytic refining workshop as the restoration object, the implementation steps are as follows:

[0042] a. Put the scrapped conductive rod in water with a temperature above 90°C, and boil it until there is no green and other dirt on the surface;

[0043] b. Repair the corrosion cracks existing on the surface of the scrapped conductive rods, and the treatment methods for different corrosion conditions on the surface of the scrapped conductive rods are as follows: (1) The overall corrosion of the conductive rods, the weight is significantly reduced, and the surface cracks are small, The measure to be taken is to directly prepare for electrolysis; (2) There are many corrosion cracks on the overall surface of the conductive rod, and the measure to be taken is to prepare the electrolysis after the surface is polished; (3) The conductive rod is partially corroded with deep cracks, exposing the internal iron rod, and the mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com