A deashing treatment method for a coal sample applied for XRD test analysis

A treatment method and test analysis technology, applied in the preparation of test samples, material analysis using radiation diffraction, etc., can solve problems such as the influence of organic matter diffraction front fitting, and achieve the effects of saving test costs, improving efficiency, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

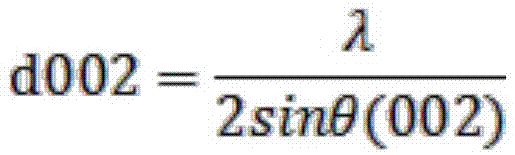

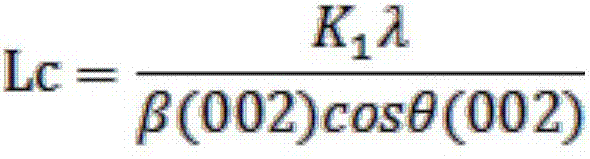

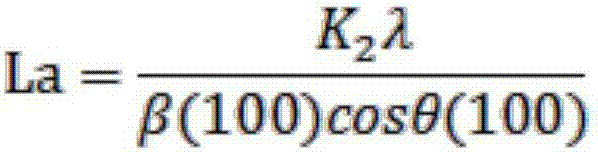

Method used

Image

Examples

example 1

[0037]Take about 5 grams of an air-dried coal sample that has been finely ground to 200 mesh, with an ash content of 4.9%, add 30ml of 10% hydrochloric acid, and stir fully with a glass rod, so that the coal sample is completely wetted by hydrochloric acid. Cover the beaker, place the beaker in a constant temperature water bath at 60°C, stir every 5 to 10 minutes, take out the beaker after 40 minutes and let it stand for a while, then filter with slow qualitative filter paper. Wash the coal sample remaining on the filter paper into a plastic beaker until the volume of the washing liquid is close to 2-3ml, then add 10ml of concentrated hydrochloric acid, 20ml of concentrated hydrofluoric acid (concentration 20%) and 10ml of nitric acid (concentration 20%). Stir with a stick, stir once every 5-10 minutes in a constant temperature water bath at 55-60 degrees, take out the beaker after 40-50 minutes and let it stand for a while, filter it with slow qualitative filter paper, wash it...

example 2

[0039] Take about 8 grams of an air-dried coal sample that has been finely ground to 200 mesh, with an ash content of 5.4%, add 30ml of 10% hydrochloric acid, and stir fully with a glass rod, so that the coal sample is completely wetted by hydrochloric acid. Cover the beaker, place the beaker in a constant temperature water bath at 60°C, stir once every 5-10 minutes, take out the beaker after 40 minutes and let it stand for a while, repeat twice, and filter with slow qualitative filter paper. Wash the coal sample remaining on the filter paper into a plastic beaker until the volume of the washing liquid is close to 2-3ml, then add 20ml concentrated hydrochloric acid, 30ml concentrated hydrofluoric acid (concentration 20%) and 10ml nitric acid (concentration 20%). Stir with a rod, automatically stir for 2 hours, take out the beaker and let it stand still, filter with slow qualitative filter paper, after repeated washing, put the coal sample in a constant temperature drying oven a...

example 3

[0041] Dilute 200ml of 36.5% concentrated hydrochloric acid to 400ml of hydrochloric acid solution at a mass ratio of 1:1, and put it into a reagent bottle for use. Weigh 10 grams of the sample, pour it into a polytetrafluoroethylene beaker, then add 300ml of diluted hydrochloric acid, and stir for 1 hour under a stirrer. The coal sample was filtered out to obtain a once-acid-washed sample. Put the sample back into the beaker, add 50ml of hydrofluoric acid, and stir for 2 hours under the stirrer to fully react the hydrofluoric acid and coal. Filter out the coal sample to obtain the sample of secondary pickling; put the sample back into the beaker, add 30ml of concentrated hydrochloric acid, put it under the stirrer and stir for 1h. The coal sample was filtered to obtain a three-washed sample. Put the sample back into the beaker, add 30ml of nitric acid (concentration 20%), stir for 1h, let it stand for 10h, filter out the coal sample, and wash it with deionized water until t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com