A Partial Grating Electroabsorption Modulation Laser and Its Design Method

An electro-absorption modulation and laser technology, applied in the field of lasers, can solve the problems of difficult chip packaging, high price, and high requirements for coating equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

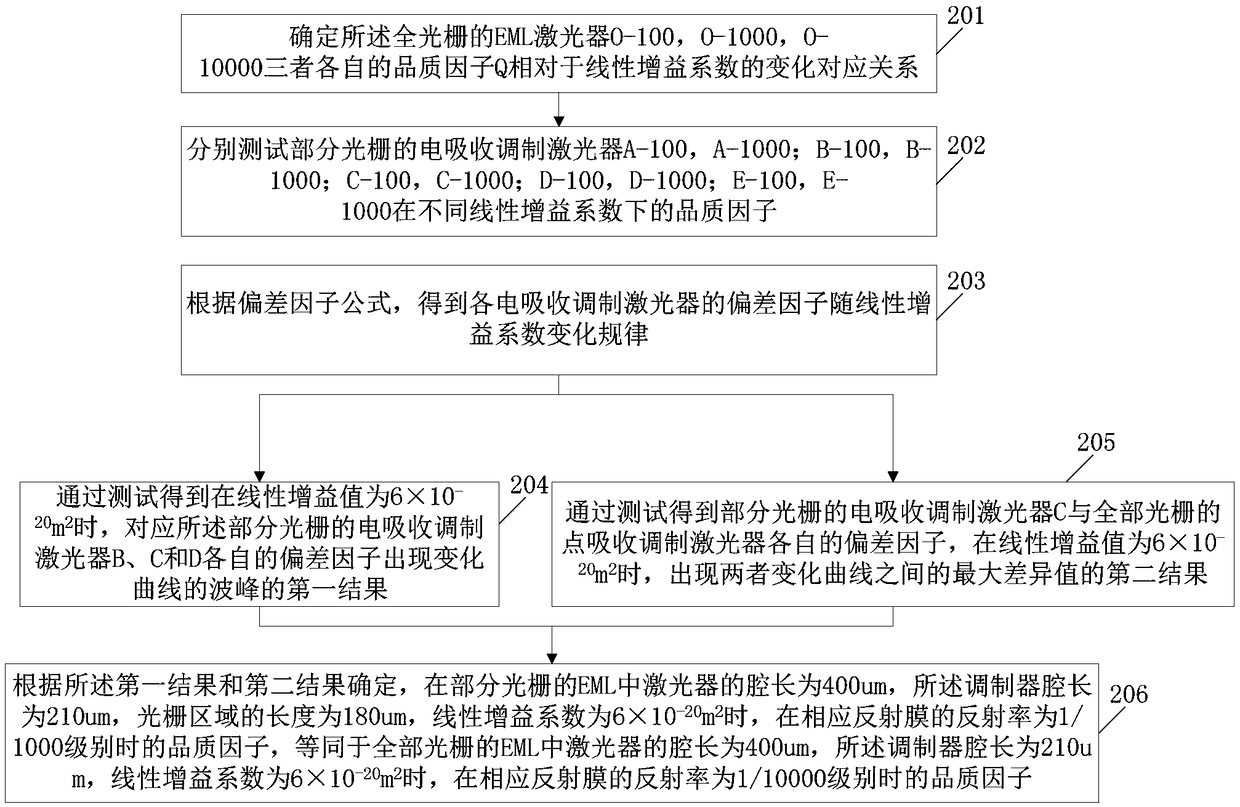

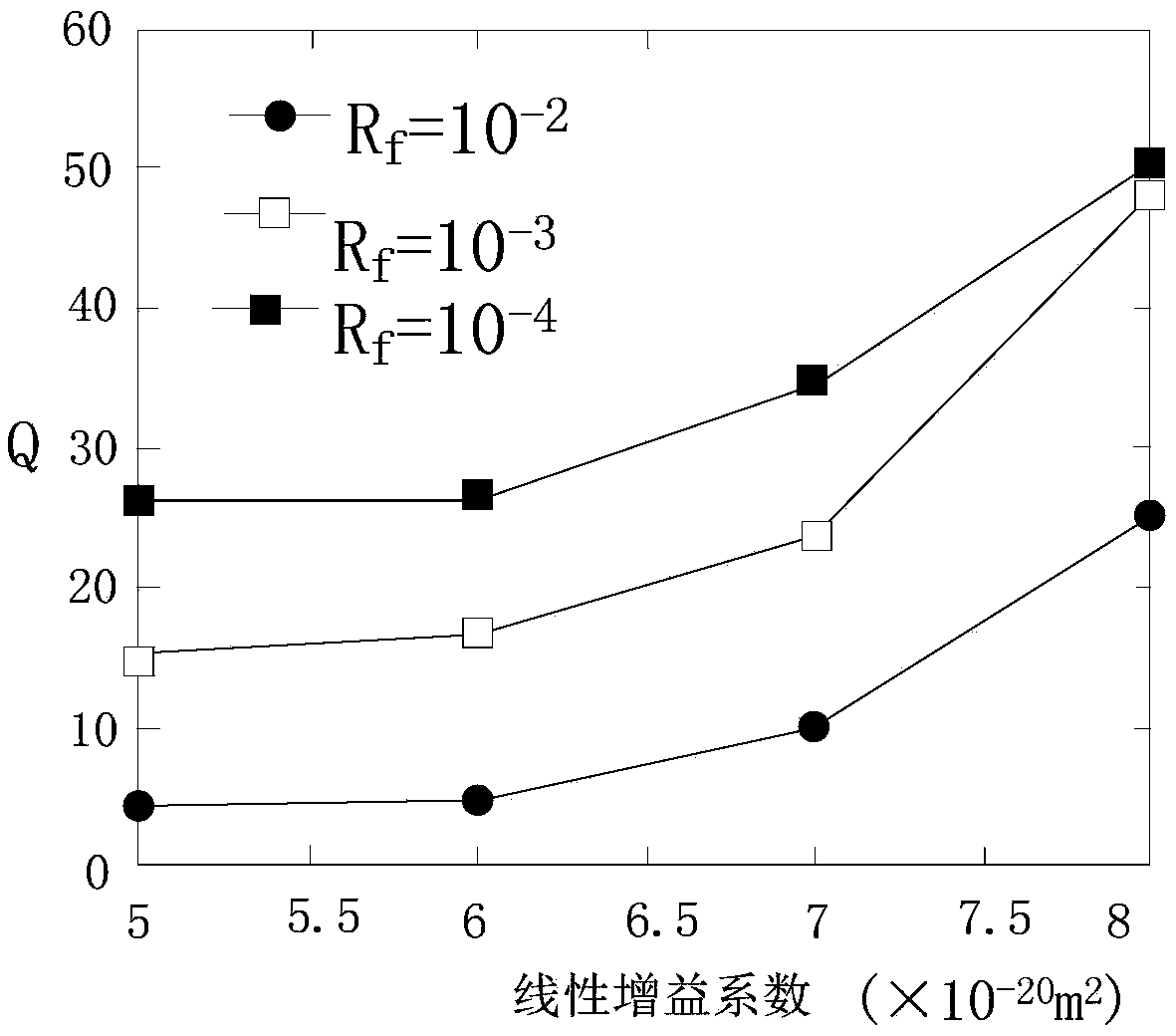

[0039] Embodiment 1 of the present invention provides a method for designing an electro-absorption modulated laser of a partial grating. The electro-absorption modulated laser O of the entire grating and the electro-absorption modulated laser of a part of the grating are prepared respectively, wherein the electro-absorption modulated laser of the entire grating (Electro- Absorption modulated laser, abbreviated as: EML) O parameters include that the cavity length of the laser is 400um, the cavity length of the modulator is 210um, and the length of the grating region is 400um; wherein, the electroabsorption modulated laser of the partial grating includes A, B, C, D and E five, the electroabsorption modulation laser A, B, C, D and E of partial grating The same parameter includes the cavity length of the laser is 400um, the cavity length of the modulator is 210um, the difference is The length of the grating area of the electro-absorption modulation laser A of the partial grating ...

Embodiment 2

[0056] On the basis of the test conclusions and design ideas given in Example 1 by the embodiment of the present invention, a partial grating electro-absorption modulated laser is also proposed. The partial grating electro-absorption modulated laser is composed of a laser region and a modulator region, wherein the laser region It also includes a grating-free region and a region provided with a Bragg grating, and the region provided with a Bragg grating is coupled to the modulator region, such as Figure 6 As shown, specifically:

[0057] The laser cavity length L DFB is 350um-450um, the cavity length L of the modulator EAM is 180-270um, wherein the length Lg of the grating region in the laser is 150-200um;

[0058] The linear gain coefficient of the electroabsorption modulation laser of the partial grating is controlled at 5-7×10 -20 m 2 between;

[0059] The reflectance of the reflective film on the light-emitting surface of the modulator area of the electroabsorption ...

Embodiment 3

[0063] The embodiment of the present invention is based on the structure of the partial grating electro-absorption modulation laser C used for testing in Example 1, and proposes a partial grating electro-absorption modulation laser. The partial grating electro-absorption modulation laser consists of a laser region and a modulator region constitute, wherein, the laser region includes a grating-free region and a region provided with a Bragg grating, and the region provided with a Bragg grating is coupled with the modulator region, referring to Figure 6 As shown, specifically:

[0064] The laser cavity length L DFB is 400um, the cavity length L of the modulator EAM is 210um, the length L of the non-grating area is 220um, and the length Lg of the grating area is 180um;

[0065] The linear gain coefficient of the electroabsorption modulation laser of the partial grating is controlled at 6×10 -20 m 2 ;

[0066] The reflectance of the reflective film on the light-emitting surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com