Feeding unit of optical film vision intelligent detection device

A detection equipment and visual intelligence technology, applied in the direction of thin material processing, winding strips, sending objects, etc., can solve the problems of missing brightening film, low reliability, false detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

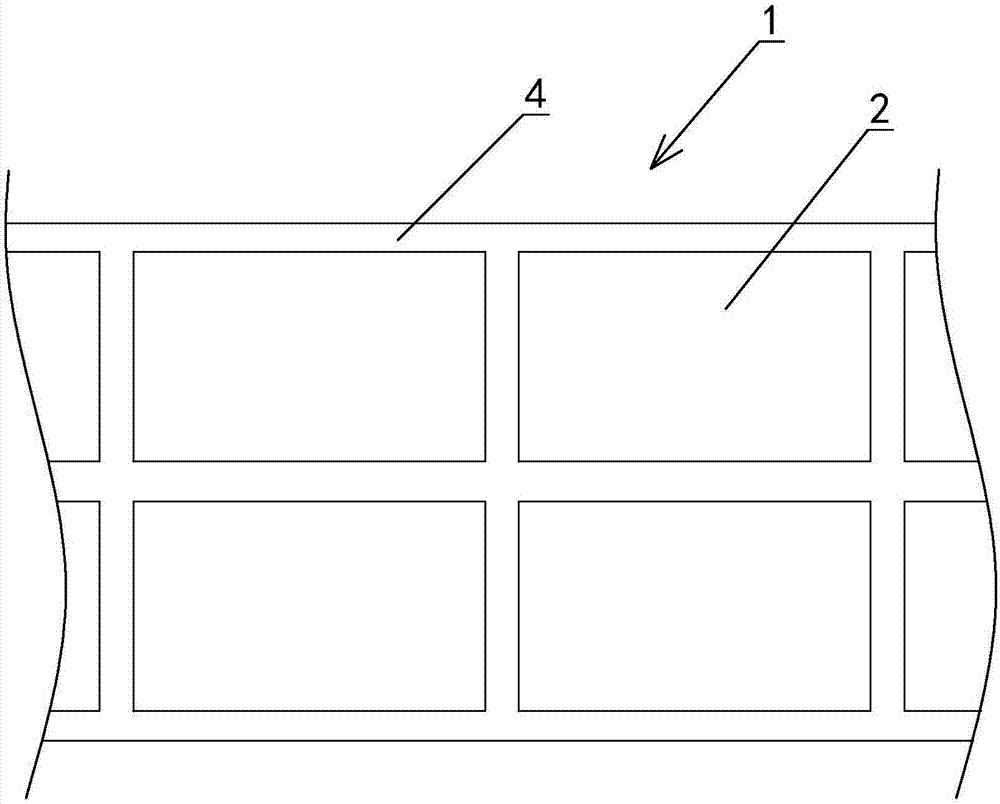

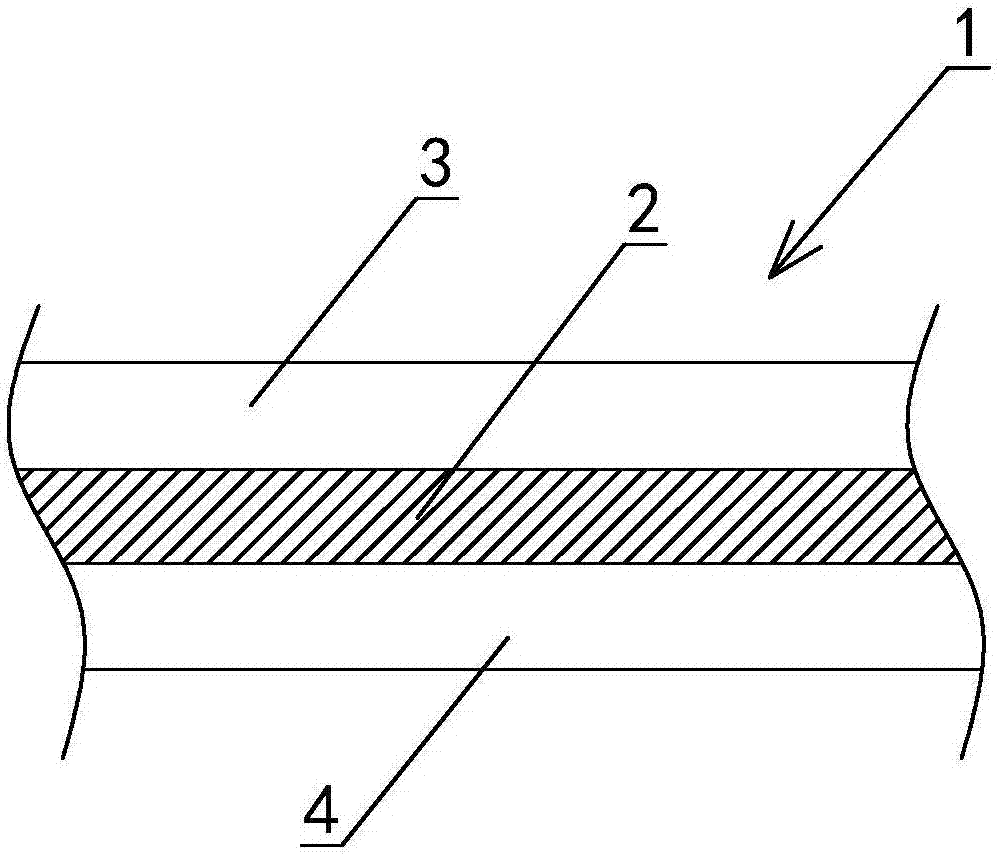

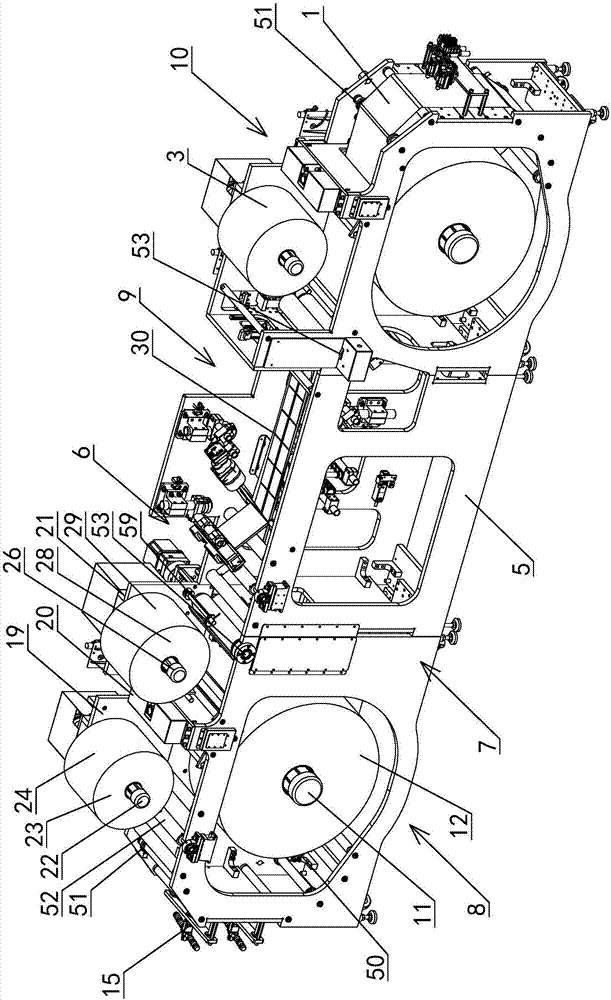

[0058] Example: see attached Figure 1-10 As shown, a feeding unit of an optical film vision intelligent detection device, the detection device is used to detect the optical film product 2 in the optical film material belt 1, and the optical film material belt 1 is composed of a protective film 3, an optical film product 2 and the base film 4 are combined from top to bottom (such as figure 1 , 2 ).

[0059] Described detection equipment comprises a frame 5, and the length direction of this frame 5 is the X-axis direction, and the width direction of frame 5 is the Y-axis direction; Displaced backward, the frame 5 is divided into an upper space 6 and a lower space 7 in the Z-axis direction based on the optical film strip 1;

[0060] The detection equipment also includes a feeding unit 8, a detection unit 9 and a receiving unit 10 arranged in the frame 5 from front to back along the X-axis direction; wherein,

[0061] Described feeding unit 8 comprises:

[0062] A feeding mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com