Low-carbon alkane dehydrogenation process

A low-carbon alkanes and process technology, applied in the field of dehydrogenation of low-carbon alkanes, can solve the problems of short operating life and fast carbon deposition, and achieve the effects of low Cr content, good selectivity, and long single-pass operating cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

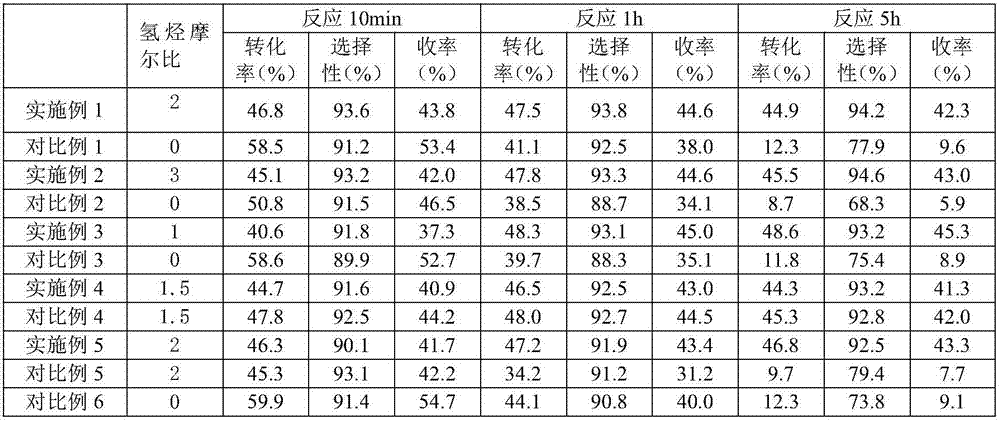

Embodiment 1

[0031] Weigh 3.4g Cr(NO 3 ) 3 9H 2 O, 0.3g KNO 3 , 0.375g Cu(NO 3 ) 2 ·3H 2 O, 1.35g Ni(NO 3 ) 2 ·6H 2 O, dissolved in 4.6ml deionized water, impregnated to 5.2g active Al 2 o 3 powder on. Keep at 60°C for 12h, dry at 120°C for 2h, calcinate at 750°C for 5h, and form and sieve to obtain the catalyst, which is designated as Catalyst A. Butane hydrodehydrogenation, the results are shown in Table 1.

Embodiment 2

[0035] Weigh 0.3g Cr 2 o 3 , dissolved in 20ml 0.3molL -1 HNO 3 In, add 7.97g pseudo-boehmite powder (Al 2 o 3 Content 64wt.%), stir to make it fully peptized. Then add 0.3g KNO 3 , 1.45g Co(NO 3 ) 2 ·6H 2 O, fully dissolved by stirring, slowly evaporated to dryness under stirring at 70°C, dried at 120°C for 10 hours, calcined at 720°C for 6 hours, and the catalyst was obtained after molding and sieving, which was designated as catalyst B. Butane hydrodehydrogenation, the results are shown in Table 1.

Embodiment 3

[0039] Weigh 3.75g Al(NO 3 ) 3 9H 2 O, 0.28g Cr(NO 3 ) 3 9H 2 O, 0.126g Fe(NO 3 ) 3 9H 2 O, 0.04g Co(NO 3 ) 2 ·6H 2 O, dissolve in 20ml deionized water, add 30ml 1.5molL dropwise under stirring -1 NH 3 solution, airtight at 60 ° C for 12 hours. Filtered and washed, then the precipitate was added to 1 g of 2.0wt% K 2 CO·solution, beating and mixing evenly, drying at 90°C for 12 hours, calcining at 700°C for 20 hours, forming and sieving to obtain the catalyst, which is designated as Catalyst C. Butane hydrodehydrogenation, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com