High-temperature electric heating film of flexible nano-carbon composite material and preparation method of high-temperature electric heating film

An electric heating film and composite material technology, which is applied in the field of composite materials, can solve the problems of poor adhesion of high-temperature resistant film layers, etc., and achieve the effects of good moisture resistance, wide application fields, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

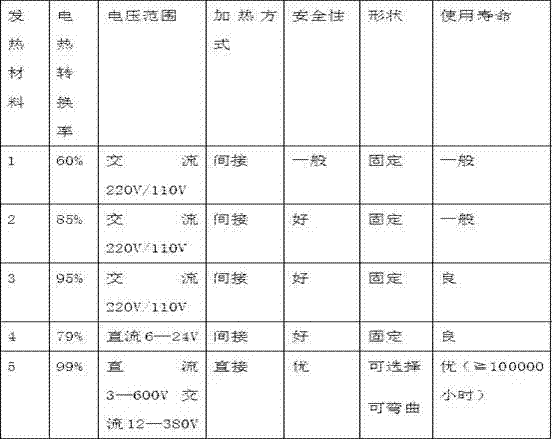

Image

Examples

Embodiment 1

[0020] The flexible nano-carbon composite high-temperature electric heating film is composed of electric heating film paddle material and glass fiber cloth. Its characteristics are: the electric heating film paddle material is composed of solid material and solvent according to the mass percentage of 20%:80%. Among them, The solid material is composed of graphite, carbon black, silver, zinc oxide and rare earth materials with a particle size of less than 50nm in a mass ratio of 5:2:1:2:0.5. The solvent includes xylene, dimethylamide, polyamide resin and polyamide resin. The imide polymer solution is 1:4:1:4 by mass.

Embodiment 2

[0022] The flexible nano-carbon composite high-temperature electric heating film is composed of electric heating film paddle material and glass fiber cloth. Its characteristics are: the electric heating film paddle material is composed of solid materials and solvents at a mass percentage of 40%:60%. Among them, The solid material is composed of graphite, carbon black, silver, zinc oxide and rare earth materials with a particle size of less than 50nm in a mass ratio of 5:2:1:2:0.5. The solvent includes xylene, dimethylamide, polyamide resin and polyamide. The imide polymer solution is 1:4:1:4 by mass.

Embodiment 3

[0024] The flexible nano-carbon composite high-temperature electric heating film is composed of electric heating film paddle material and glass fiber cloth. It is characterized in that: the electric heating film paddle material is composed of solid materials and solvents at a mass percentage of 30%:70%. Among them, The solid material is composed of graphite, carbon black, silver, zinc oxide and rare earth materials with a particle size of less than 50nm in a mass ratio of 5:2:1:2:0.5. The solvent includes xylene, dimethylamide, polyamide resin and polyamide resin. The imide polymer solution has a mass ratio of 1:4:1:4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com