Imitated-marble whole-body ceramic tile and preparation method thereof

A technique of imitating marble and ceramic tiles, which is applied in the field of imitating marble whole-body ceramic tiles and its preparation, can solve the problems of reduced simulation degree, melting deformation, low strength, etc., reduce firing temperature, increase porcelain forming rate, and improve simulation degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A marble imitation ceramic brick, the thickness of which is 1cm, comprises a whole body brick layer and a surface glaze layer applied on the whole body brick layer.

[0036] Wherein the whole body adobe layer comprises the following components in terms of raw material weight percentage:

[0037]

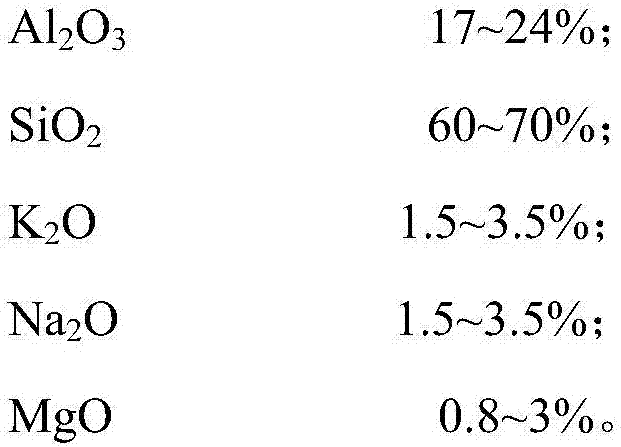

[0038] And, this adobe comprises following chemical composition by weight percentage:

[0039]

[0040] Wherein the surface glaze layer comprises the following components in terms of raw material weight percentage:

[0041]

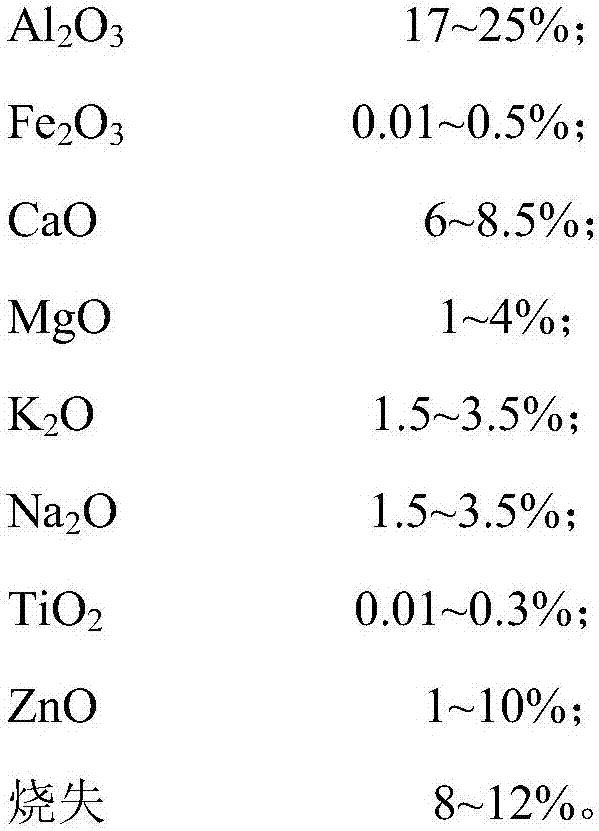

[0042] And, this surface glaze comprises following chemical composition by raw material weight percentage:

[0043]

[0044]Specifically, the potassium content of the potassium sand is 3%; the aluminum content of the black mud is 22%.

[0045] Preparation:

[0046] 1) Slurry preparation: Mix all components except toner evenly according to the weight percentage of raw materials, and put them into a ball mill for wet ball milling. The moistu...

Embodiment 2

[0053] A marble imitation ceramic brick, the thickness of which is 1.3cm, comprises a whole body adobe layer and a surface glaze layer applied on the whole body adobe layer.

[0054] Wherein the whole body adobe layer comprises the following components in terms of raw material weight percentage:

[0055]

[0056] And, this adobe comprises following chemical composition by weight percentage:

[0057]

[0058] Wherein the surface glaze layer comprises the following components in terms of raw material weight percentage:

[0059]

[0060]

[0061] And, this surface glaze comprises following chemical composition by raw material weight percentage:

[0062]

[0063] Specifically, the potassium content of the potassium sand is 8%; the aluminum content of the black mud is 32%.

[0064] Preparation:

[0065] 1) Slurry preparation: Mix all components except toner evenly according to the weight percentage of raw materials, and put them into a ball mill for wet ball milli...

Embodiment 3

[0072] A marble imitation ceramic brick, the thickness of which is 1.1cm, comprises a whole body adobe layer and a surface glaze layer applied on the whole body adobe layer.

[0073] Wherein the whole body adobe layer comprises the following components in terms of raw material weight percentage:

[0074]

[0075] And, this adobe comprises following chemical composition by weight percentage:

[0076]

[0077] Wherein the surface glaze layer comprises the following components in terms of raw material weight percentage:

[0078]

[0079] And, this surface glaze comprises following chemical composition by raw material weight percentage:

[0080]

[0081]

[0082] Specifically, the potassium content of the potassium sand is 4%; the aluminum content of the black mud is 28%.

[0083] Preparation:

[0084] 1) Slurry preparation: Mix all components except toner evenly according to the weight percentage of raw materials, and put them into a ball mill for wet ball milli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com