Preparation process of sodium stearoyl lactylate

A technology of sodium stearoyl lactylate and preparation process, applied in the chemical field, can solve the problems of high price of stearic acid, increase production cost, long process route, etc., and achieve the effects of preventing darkening of color, reducing peculiar smell, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

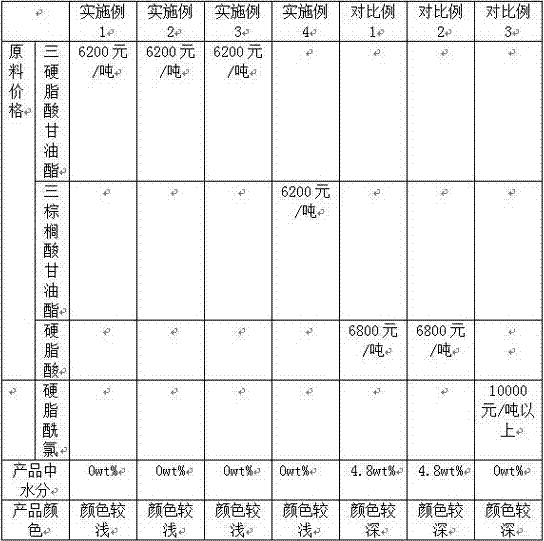

Examples

Embodiment 1

[0020] The preparation technology of present embodiment sodium stearoyl lactylate, this preparation technology, concrete steps are as follows:

[0021] (1) Heat lactic acid to 110°C under the condition of -0.09MPa for concentration and dehydration to obtain concentrated lactic acid;

[0022] (2) Send 10mol glyceryl tristearate and 40mol concentrated lactic acid into the reaction kettle, add sodium hydroxide and pass nitrogen into the reaction kettle, nitrogen replacement 3 times, nitrogen pressure is -0.09MPa, at 220 ℃ Stirring and reacting for 2 hours under certain conditions to obtain sodium stearoyl lactylate.

Embodiment 2

[0024] The preparation technology of present embodiment sodium stearoyl lactylate, this preparation technology, concrete steps are as follows:

[0025] (1) Heat lactic acid to 80°C under the condition of 0.06MPa to concentrate and dehydrate to obtain concentrated lactic acid;

[0026] (2) Send 10mol glyceryl tristearate and 80mol concentrated lactic acid into the reaction kettle with a molar ratio of 10mol, add an alkali catalyst and feed nitrogen into the reaction kettle, replace the nitrogen gas 4 times, and fill the nitrogen gas with a pressure of 0.06MPa. The reaction was stirred under the condition of ℃ for 8 hours to obtain sodium stearoyl lactylate.

Embodiment 3

[0028] The preparation technology of present embodiment sodium stearoyl lactylate, this preparation technology, concrete steps are as follows:

[0029] (1) Heat lactic acid to 95°C under the condition of -0.02MPa to concentrate and dehydrate to obtain concentrated lactic acid;

[0030] (2) Send 10mol glyceryl tristearate and 60mol concentrated lactic acid into the reaction kettle with a molar ratio of 10mol, add an alkali catalyst and feed nitrogen into the reaction kettle, replace the nitrogen three times, and fill the nitrogen with a pressure of -0.02MPa. Stir the reaction at 155°C for 5 hours to obtain sodium stearoyl lactylate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com