Production process of acetamiprid

A production process and acetamiprid technology are applied in the production process field of acetamiprid, which can solve the problems of high odor of methylamine, high by-products, large amount of waste water, etc., and achieves less three wastes, less by-products, and high total yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

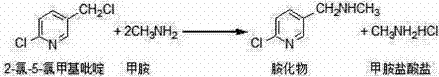

[0019] The production technology of acetamiprid comprises the following steps:

[0020] (1) Amination: Add 3500L dichloroethane to the amination reaction kettle, cool down to below 0°C, pass 310kg of monomethylamine gas into the solvent, raise the temperature to 45°C after completion, and drop 750kg into the reaction kettle 2-Chloro-5-chloromethylpyridine, after 8 hours of dropwise addition, keep warm at this temperature for 4 hours after the dropwise addition, after the reaction is completed, release the pressure and discharge the amine, and the discharged methylamine is passed into the absorption tank, passed through dichloroethane After absorption, it is used in the next batch. After the amine is discharged, the temperature is lowered to below 25°C and filtered, and the monomethylamine hydrochloride is filtered out. The filtrate is transferred to the next step after removing dichloroethane.

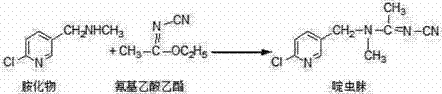

[0021] (2) Condensation: Put the materials in the previous step into the reactor, ...

Embodiment 2

[0023] The production technology of acetamiprid comprises the following steps:

[0024] (1) Amination: Add 3500L tetrahydrofuran into the amination reaction kettle, cool down to below 0°C, pass 310kg of monomethylamine gas into the solvent, raise the temperature to 45°C after completion, and drop 750kg of 2-chloro -5-Chloromethylpyridine, the 8-hour dropwise addition is completed. After the dropwise addition, the temperature is kept at this temperature for 4 hours. Batches, after amine removal, lower the temperature to below 25°C and filter, filter out monomethylamine hydrochloride, remove tetrahydrofuran from the filtrate and transfer to the next step of reaction.

[0025] (2) Condensation: Put the materials in the previous step into the reactor, raise the temperature to 75°C, add 520kg of cyanoethyl ester dropwise, and add dropwise for 5 hours. , to get acetamiprid, and then dry to obtain 990kg of finished product, with a content of 98.5% and a yield of 95%.

Embodiment 3

[0027] The production technology of acetamiprid comprises the following steps:

[0028] (1) Amination: Add 3500L toluene to the amination reaction kettle, cool down to below 0°C, pass 310kg of monomethylamine gas into the solvent, raise the temperature to 45°C after completion, and drop 750kg of 2-chloro -5-Chloromethylpyridine, the 8-hour dropwise addition is completed, the dropwise addition is completed, and the temperature is kept at this temperature for 4 hours. After the reaction is completed, the pressure is released and the amine is discharged. Batch, after amine removal, lower the temperature to below 25°C and filter, filter out monomethylamine hydrochloride, and transfer the filtrate to the next step after removing toluene.

[0029] (2) Condensation: Put the materials in the previous step into the reactor, raise the temperature to 75°C, add 520kg of cyanoethyl ester dropwise, and add dropwise for 5 hours. , to get acetamiprid, and then dry to obtain 980kg of finished...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com