Method for regulating light softening degree of PAAB/PMMA mixed film by adjusting of content of aminoazobenzene

An aminoazobenzene and mixed membrane technology, applied in the field of controlling the mechanical properties of polymer films, can solve the problems of complex preparation process, expensive equipment, low efficiency, etc., and achieve the effects of short processing time, small material loss, and simple and fast operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1, a kind of method that regulates the photosoftening degree of PAAB / PMMA mixed film by regulating aminoazobenzene content, steps are as follows:

[0019] Step 1, the preparation method of PAAB / PMMA mixed film:

[0020] 1-1) Treatment of glass slides: First, ultrasonically clean the glass slides successively with distilled water and absolute ethanol, and then place them in a mixed solution of hydrogen peroxide / ammonia water / deionized water, wherein, hydrogen peroxide: ammonia water: deionized water The volume ratio is 1:1:5, heated at 70°C for 10 minutes, rinsed with deionized water, and dried for later use;

[0021] 1-2) Mix polyaminoazobenzene polymethyl methacrylate evenly, wherein the mass fraction of polyaminoazobenzene is ω=0.2, dissolve the mixture in tetrahydrofuran, wherein the mass fraction of the mixture in tetrahydrofuran is 10%, fully stirred for 24 hours to obtain a mixed solution;

[0022] 1-3) Using the glass slide treated in step 1-1) as a ...

Embodiment 2

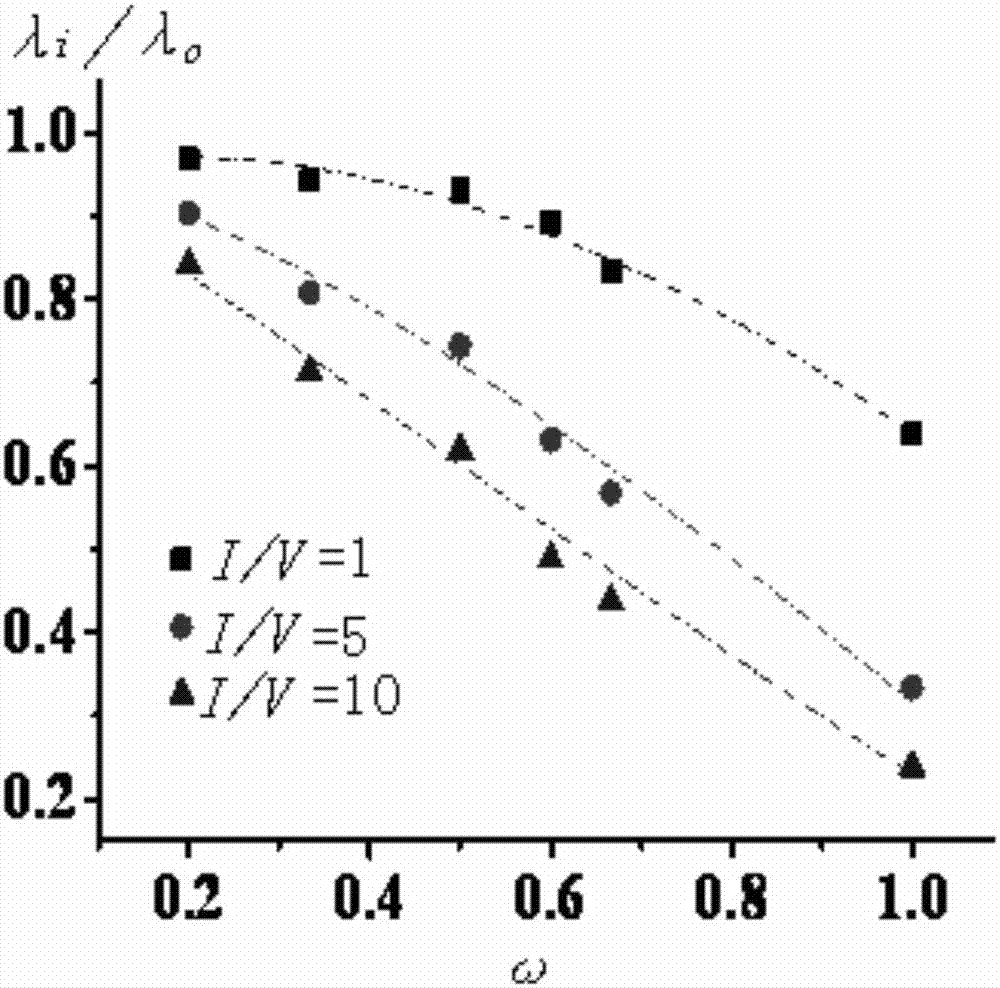

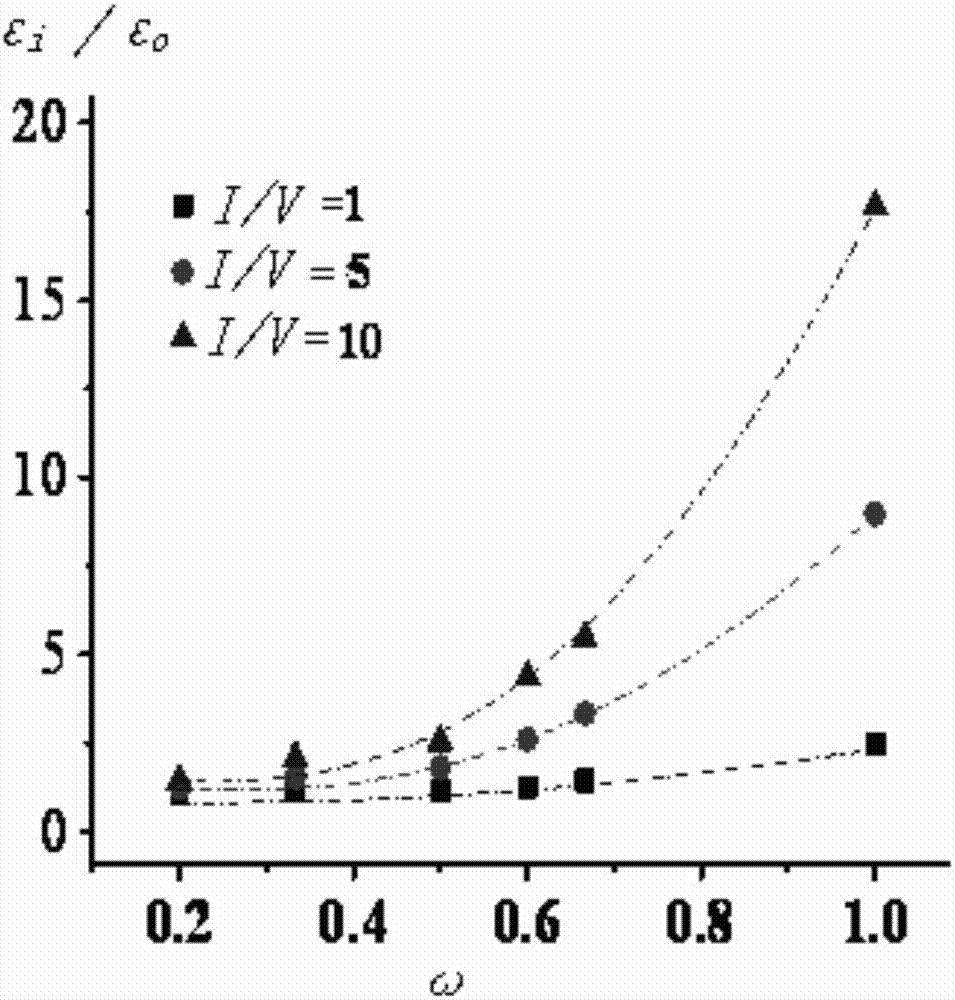

[0027] Embodiment 2: a kind of method that regulates the photosoftening degree of PAAB / PMMA mixed film by regulating aminoazobenzene content, embodiment 2 is basically the same as embodiment 1, difference is only in 1-2) the polyaminoazobenzene The mass fraction ω was adjusted to 0.32, and the other steps were unchanged. The photosoftening degree of the finally prepared PAAB / PMMA hybrid film is as follows: figure 1 and figure 2 shown.

Embodiment 3

[0028] Embodiment 3: a kind of method that regulates the photosoftening degree of PAAB / PMMA mixed film by regulating aminoazobenzene content, embodiment 3 is basically the same as embodiment 1, difference is only in 1-2) the polyaminoazobenzene The mass fraction ω was adjusted to 0.5, and the other steps remained unchanged. The photosoftening degree of the finally prepared PAAB / PMMA hybrid film is as follows: figure 1 and figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com