Metal pipe and production method of same

A metal pipe and body technology, applied in the field of pipes, can solve the problem of poor corrosion resistance of the coating, and achieve the effects of heat resistance, improved hydrolysis stability, good bonding strength, and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

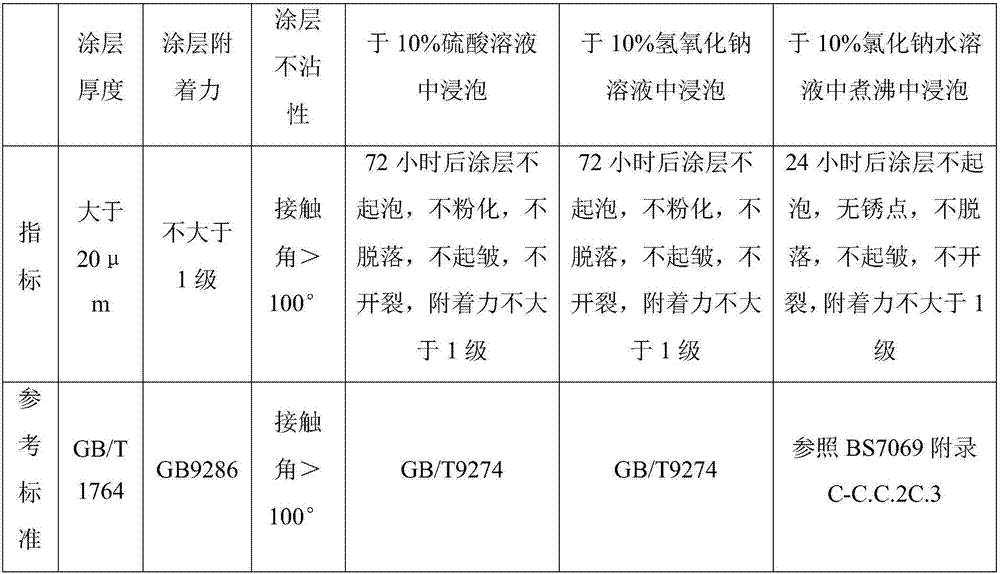

Examples

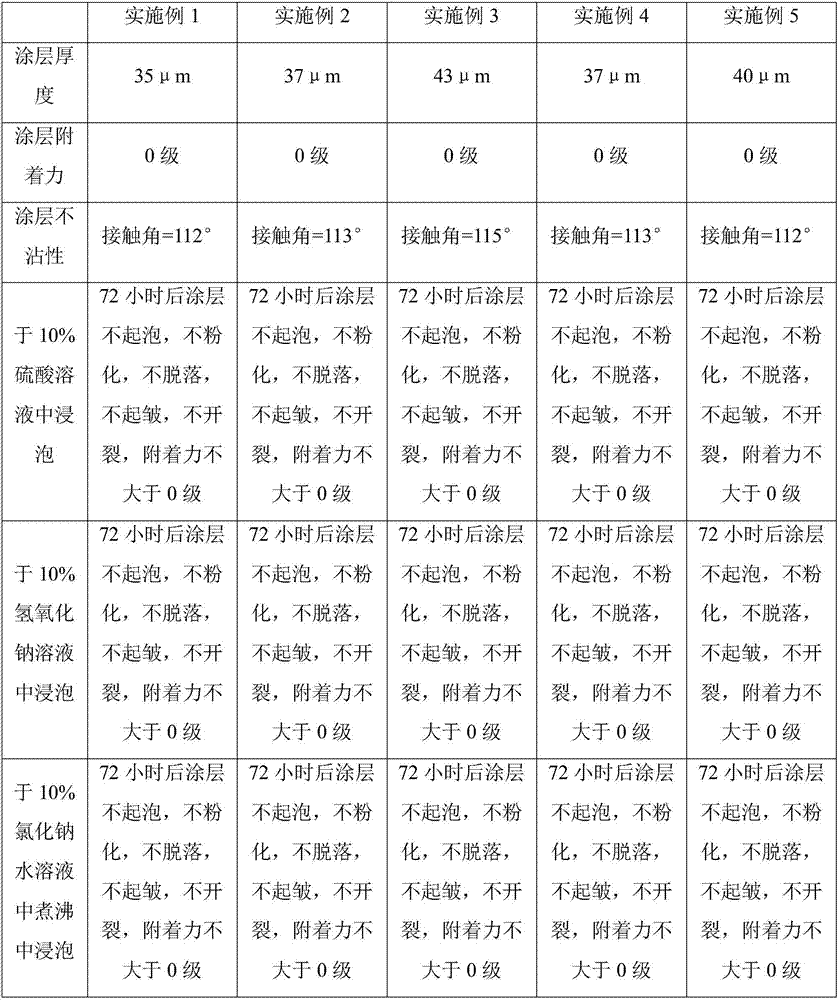

Embodiment 1

[0031] A metal pipeline includes a metal pipeline body and an anti-corrosion coating; the metal pipeline body is commercially available from China Baowu Steel Group Co., Ltd. According to the weight of the chemical composition, the metal pipe body contains 4.5 parts of Cu, 1.5 parts of Mn, 1.5 parts of Ti, 90 parts of Al, and 5 parts of Zn;

[0032] The anti-corrosion coating includes 10 parts of bisphenol A-epichlorohydrin type epoxy resin, 40 parts of N-methylpyrrolidone, 5 parts of butanone, 5 parts of pigment mixed with zinc particles, 20 parts of zinc phosphomolybdate, zinc oxide 20-40 parts, 50 parts of ethyl acetate, 40 parts of polyurethane adhesive, 60 parts of graphite powder, 10 parts of propylene oxide butyl ether, 20 parts of polyaniline, nano-CaCO 3 5 parts, nano-SiO 2 5 servings. The particle size of the above-mentioned polyaniline is selected as 600 mesh. The above polyurethane adhesives are commercially available. The above-mentioned pigments are commercia...

Embodiment 2

[0039] A metal pipeline includes a metal pipeline body and an anti-corrosion coating; the metal pipeline body is commercially available. According to the weight of the chemical composition, the metal pipe body contains 5 parts of Cu, 2 parts of Mn, 2 parts of Ti, 92 parts of Al, and 6 parts of Zn;

[0040] The anti-corrosion coating includes 12 parts of bisphenol A-epichlorohydrin type epoxy resin, 45 parts of N-methylpyrrolidone, 6 parts of butanone, 6 parts of pigment mixed with zinc particles, 25 parts of zinc phosphomolybdate, zinc oxide 25 parts, 50 parts of ethyl acetate, 40 parts of polyurethane adhesive, 60 parts of graphite powder, 12 parts of propylene oxide butyl ether, 23 parts of polyaniline, nano-CaCO 3 6 parts, nano-SiO 2 6 servings. The particle size of the above-mentioned polyaniline is selected as 600 mesh. The above polyurethane adhesives are commercially available. The above-mentioned pigments are commercially available. The weight of the zinc particle...

Embodiment 3

[0047] A metal pipeline includes a metal pipeline body and an anti-corrosion coating; the metal pipeline body is commercially available. According to the weight of the chemical composition, the metal pipe body contains 5 parts of Cu, 2 parts of Mn, 2 parts of Ti, 93 parts of Al, and 8 parts of Zn;

[0048] The anti-corrosion coating includes 15 parts of bisphenol A-epichlorohydrin type epoxy resin, 50 parts of N-methylpyrrolidone, 8 parts of butanone, 8 parts of pigment mixed with zinc particles, 30 parts of zinc phosphomolybdate, zinc oxide 30 parts, 50 parts of ethyl acetate, 40 parts of polyurethane adhesive, 60 parts of graphite powder, 15 parts of propylene oxide butyl ether, 25 parts of polyaniline, nano CaCO 3 8 parts, nano-SiO 2 8 servings. The particle size of the above-mentioned polyaniline is selected as 600 mesh. The above polyurethane adhesives are commercially available. The above-mentioned pigments are commercially available. The weight of the zinc particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com