Design method of power battery pole pieces

A design method and battery pole piece technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve problems such as fire and explosion difficulties, and achieve the effects of simple design method, improved energy density, and increased capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

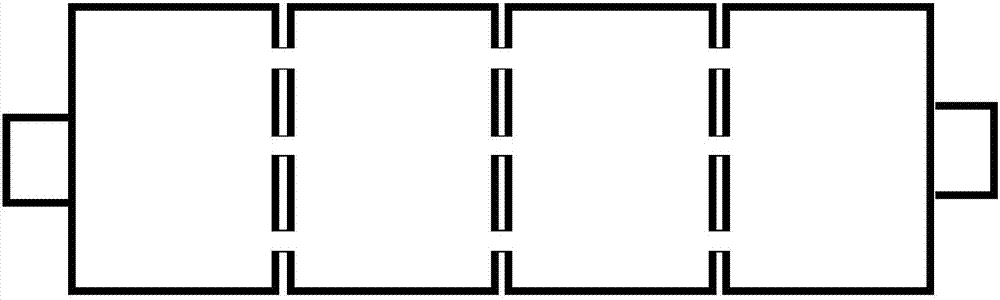

[0018] A power battery pole piece design method for reducing thermal runaway includes the following steps:

[0019] Step 1. Determine the structure of the battery core, preferably, a laminated structure;

[0020] Step 2. Determine the energy density, capacity, and size of the battery cell design;

[0021] Step 3. Using the same energy density and number of layers, cut pole pieces of different capacities and sizes, and conduct various thermal runaway initiation tests, such as acupuncture, fire, extrusion, etc., and obtain that all initiation tests can not catch fire maximum capacity and dimensions;

[0022] Step 4. In the battery that needs to be designed, divide the battery pole pieces into partitions, and each partition is not larger than the maximum size measured in step 3;

[0023] Step 5. Carry out partition slits on the pole piece, and the width of the connecting current collector left between the partitions needs to ensure that the connecting fluid can be fused when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com