A wire drawing process of a wiper arm

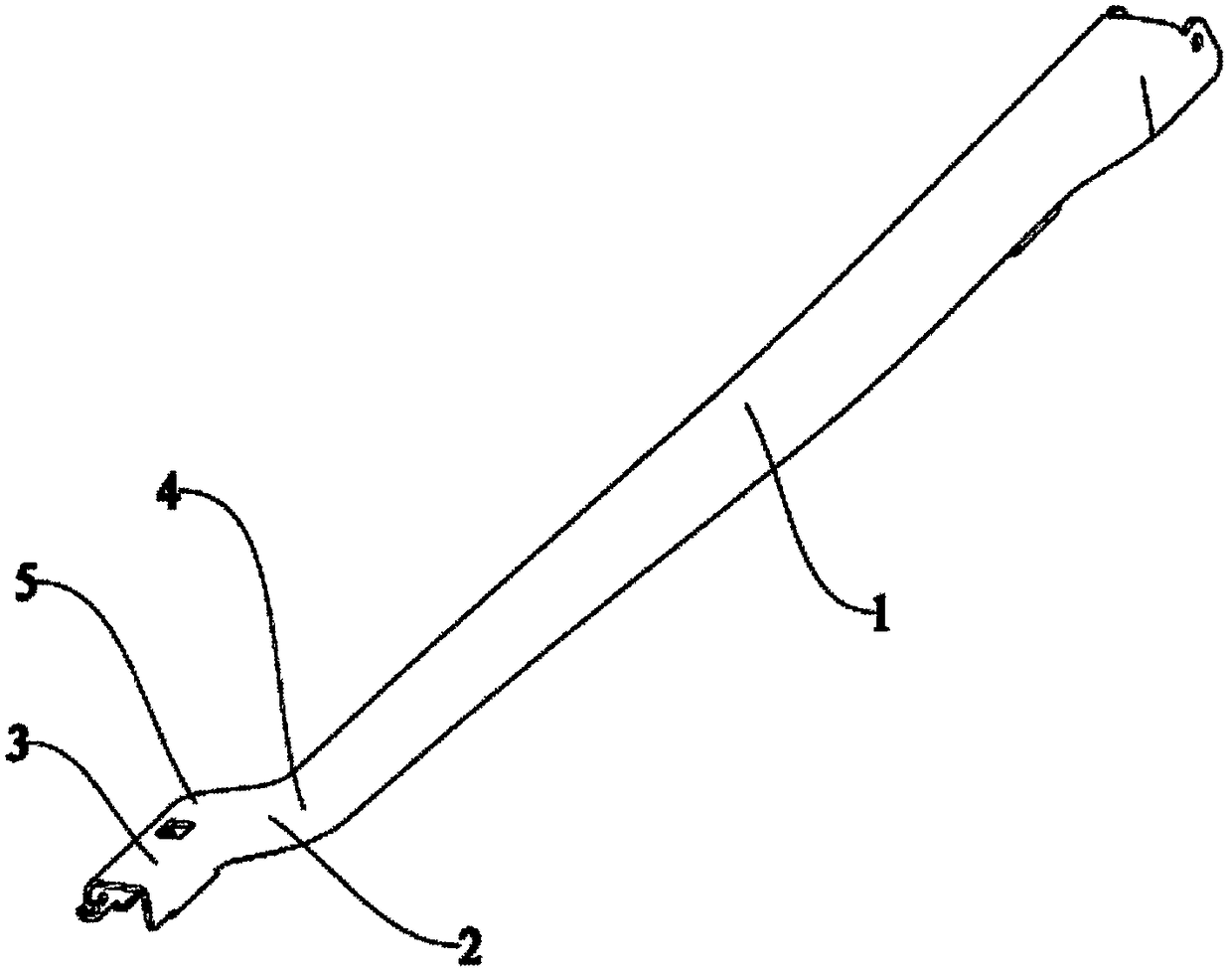

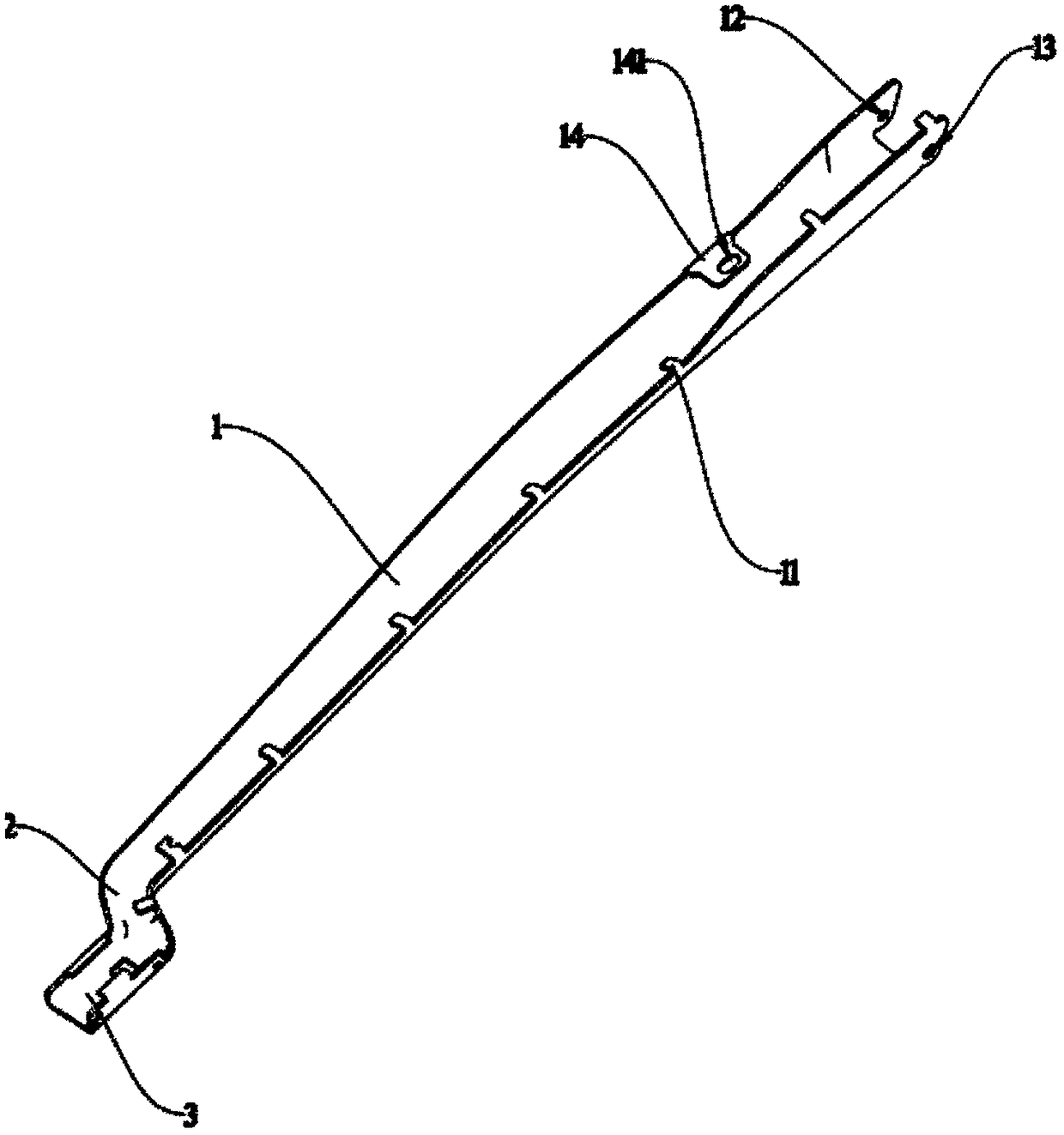

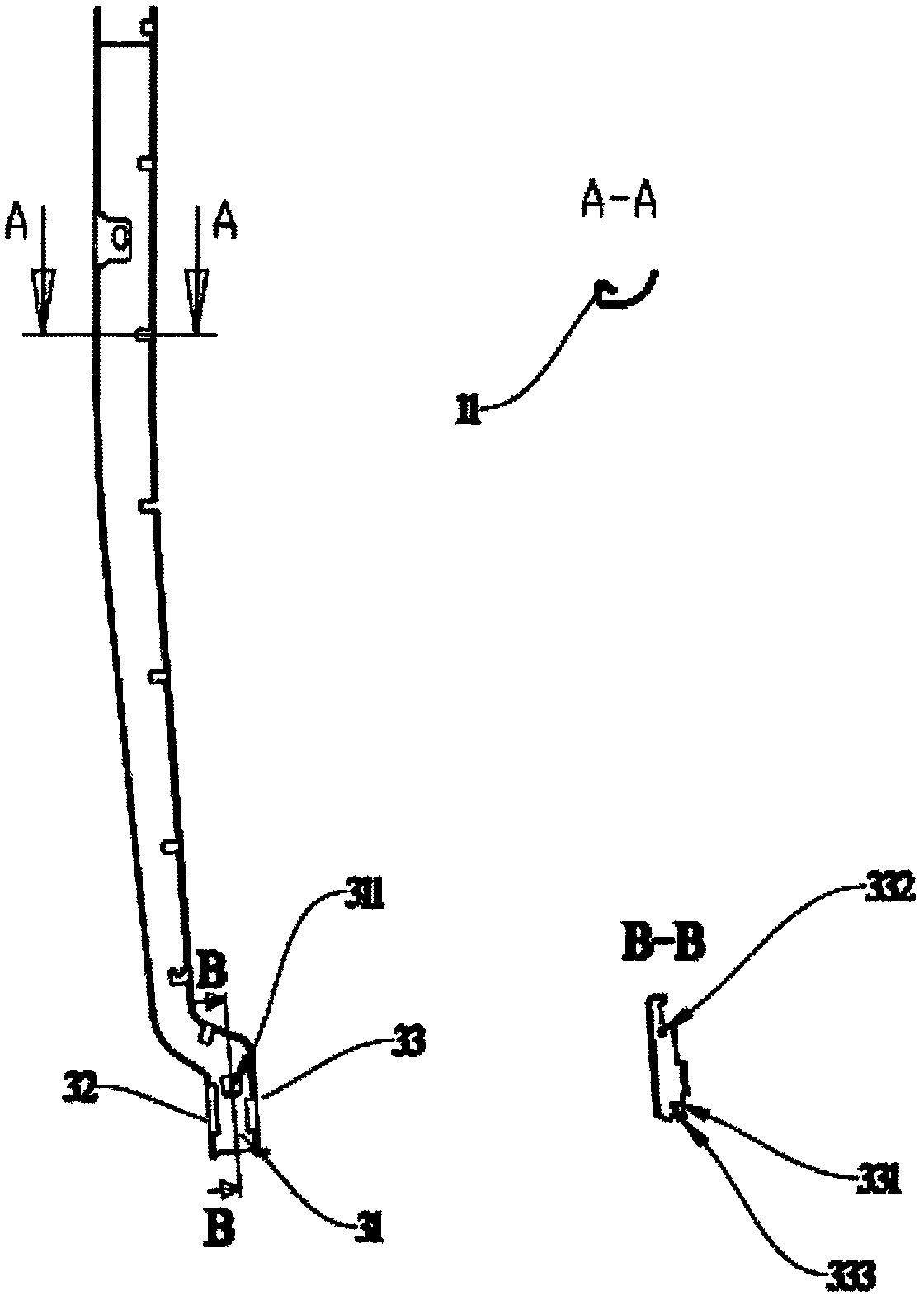

A wiper arm and process technology, which is applied in the production process of auto parts, can solve problems such as uneven stress distribution of wiper arms, failure to improve the manufacturing process, and breakage of wiper arms, so as to promote internal structure optimization and production. High efficiency and reduced pull-out force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A wire drawing process of a wiper arm. The galvanized sheet is ultrasonically drawn to obtain a wiper arm blank, and then the wiper arm blank is sequentially punched, stretched and roughly shaped to obtain a wiper arm; wherein, the ultrasonic wire drawing The specific method is: preheat the wire drawing die to 500°C, raise the temperature of the heating furnace of the wire drawing machine to 1400°C, put the galvanized sheet into the wire drawing machine for processing, apply ultrasonic excitation through the ultrasonic generator, the ultrasonic frequency is 30kHz, and the power supply The voltage is 250V, the current is 0.4A; and silica sol and graphite milk with a mass ratio of 1:1 are used as lubricants, the drawing speed is 500mm / s, and the working taper of the drawing die is 10°.

[0037] The galvanized sheet is pretreated before use, and the wiper arm blank is wiped at a high temperature of 800°C before punching. The specific steps of pretreatment are as follows:

...

Embodiment 2

[0047] A wire drawing process of a wiper arm. The galvanized sheet is ultrasonically drawn to obtain a wiper arm blank, and then the wiper arm blank is sequentially punched, stretched and roughly shaped to obtain a wiper arm; wherein, the ultrasonic wire drawing The specific method is: preheat the wire drawing die to 600°C, raise the temperature of the heating furnace of the wire drawing machine to 1500°C, put the galvanized sheet into the wire drawing machine for processing, apply ultrasonic excitation through the ultrasonic generator, the ultrasonic frequency is 40kHz, and the power supply The voltage is 300V, the current is 0.6A; and silica sol and graphite milk with a mass ratio of 1:1 are used as lubricants, the drawing speed is 600mm / s, and the working taper of the drawing die is 12°.

[0048] The galvanized sheet is pretreated before use, and the wiper arm blank is wiped at a high temperature of 900°C before punching. The specific steps of pretreatment are as follows:

...

Embodiment 3

[0058] A wire drawing process of a wiper arm. The galvanized sheet is ultrasonically drawn to obtain a wiper arm blank, and then the wiper arm blank is sequentially punched, stretched and roughly shaped to obtain a wiper arm; wherein, the ultrasonic wire drawing The specific method is: preheat the wire drawing die to 500°C, raise the temperature of the heating furnace of the wire drawing machine to 1500°C, put the galvanized sheet into the wire drawing machine for processing, apply ultrasonic excitation through the ultrasonic generator, the ultrasonic frequency is 30kHz, and the power supply The voltage is 300V, the current is 0.4A; and silica sol and graphite milk with a mass ratio of 1:1 are used as lubricants, the drawing speed is 600mm / s, and the working taper of the drawing die is 10°.

[0059] The galvanized sheet is pretreated before use, and the wiper arm blank is wiped at a high temperature of 800°C before punching. The specific steps of pretreatment are as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com