Reactable gel plugging agent and preparation method thereof

The technology of a leak-stopping agent and gel is applied in the field of reactable gel leak-stopping agent and its preparation, which can solve the problems of decreased strength, poor adaptability of the leakage layer, easy re-leakage, etc., so as to reduce repeated leakage and improve the bearing strength. and blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

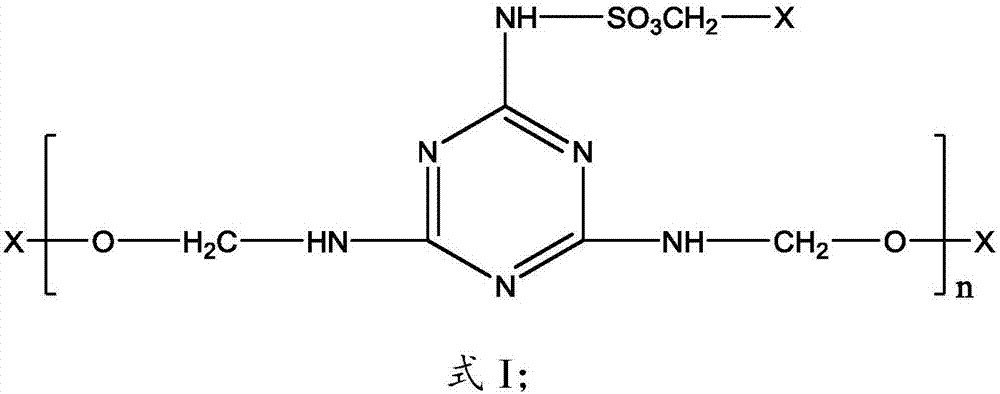

[0046] The present invention provides a method for preparing the reactive gel plugging agent according to the above technical scheme, which includes the following steps:

[0047] 1) In an alkaline environment, react formaldehyde, melamine and a sulfonating agent to obtain an intermediate product;

[0048] 2) Under the action of an initiator, the intermediate product, vinyl monomer, N,N-methylenebisacrylamide and inorganic materials are reacted to obtain a gel plugging agent;

[0049] The vinyl monomer is two of acrylamide, N,N-dimethylacrylamide, vinylpyrrolidone, N,N-diethylacrylamide and 2-acrylamide-2-methylpropanesulfonic acid Or two or more;

[0050] The inorganic materials are calcium clay, silicon powder and wood powder.

[0051] Compared with the prior art, the reactable gel plugging agent prepared by the method provided by the present invention has the function of absorbing water, swelling and deforming, and can be well adapted to the missing channel; when drilling into the mi...

Embodiment 1

[0094] Weigh 50g of formaldehyde and pour it into a four-necked flask. Adjust the pH to 8.5 with triethanolamine. Then add 23.3g of melamine. After heating in a 60℃ water bath for 10 minutes, the melamine will dissolve and form a transparent solution; this transparent solution will be quickly heated to 70℃ After the reaction for 60 minutes, add 6.8 g of sodium metabisulfite, adjust the pH to 12 with NaOH aqueous solution, and raise the temperature to 80°C, and continue the reaction for 30 minutes to obtain the intermediate product;

[0095] Add 4g AMPS (2-acrylamide-2-methylpropanesulfonic acid) and 16g AM (acrylamide) into 60g of clean water, stir well and adjust the pH to 7 with aqueous sodium hydroxide; then add 0.04g of N, N-methylene bisacrylamide, 8g calcareous soil and 120g of the above-mentioned intermediate product, after stirring and dissolving, add 0.2g potassium persulfate, 0.2g sodium sulfite, and stand to react to form a gel; take out the product to granulate A reac...

Embodiment 2

[0100] Weigh 50g of formaldehyde and pour it into a four-necked flask. Adjust the pH to 8 with triethanolamine. Then add 20g of melamine. After heating in a 65℃ water bath for 15 minutes, the melamine will dissolve and form a transparent solution; this transparent solution will be quickly heated to 80℃. After 90 minutes of reaction, add 7.4 g of sodium sulfite, adjust the pH to 12 with NaOH aqueous solution, and raise the temperature to 90°C, continue the reaction for 120 minutes to obtain the intermediate product;

[0101] Add 16gAM (acrylamide) and 1g NVP (vinylpyrrolidone) into 60g of clean water, stir well and adjust the pH to 7 with aqueous sodium hydroxide; then add 0.06g of N,N-methylenebisacrylamide, 10g of Calcium soil and 120g of the above-mentioned intermediate product; after stirring and dissolving, add 0.2g of potassium persulfate and 0.2g of sodium sulfite, and let stand to react to form a gel; take out the product and granulate to obtain a reactive gel plugging agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com