Preparation method for unsaturated polyurethane coating

A polyurethane coating, unsaturated technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of high curing temperature, long curing time, and lower product qualification rate of plastic coatings, and achieve high refractive index, good Fastness and aging resistance, good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

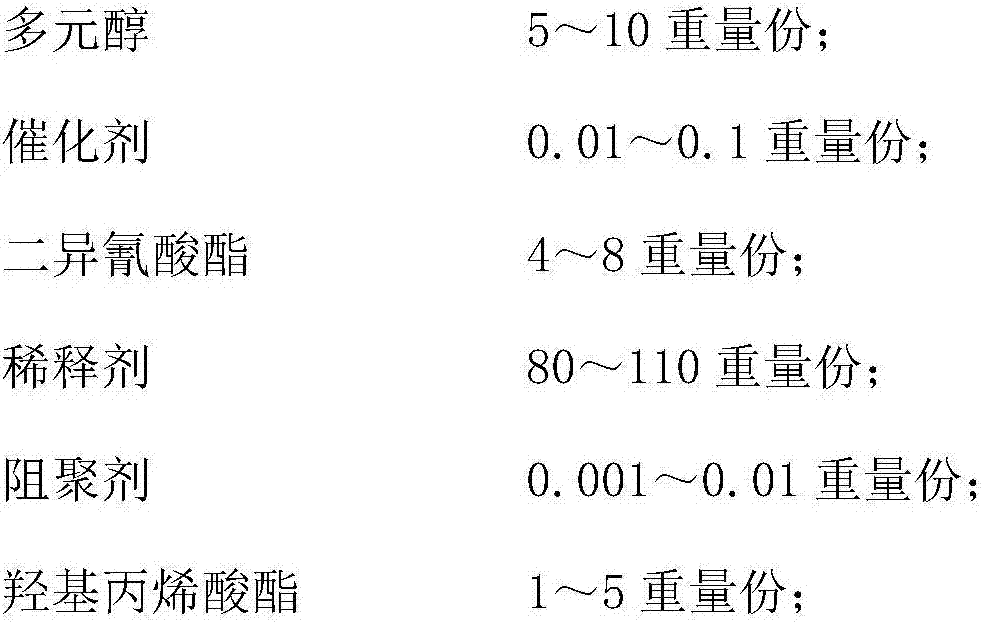

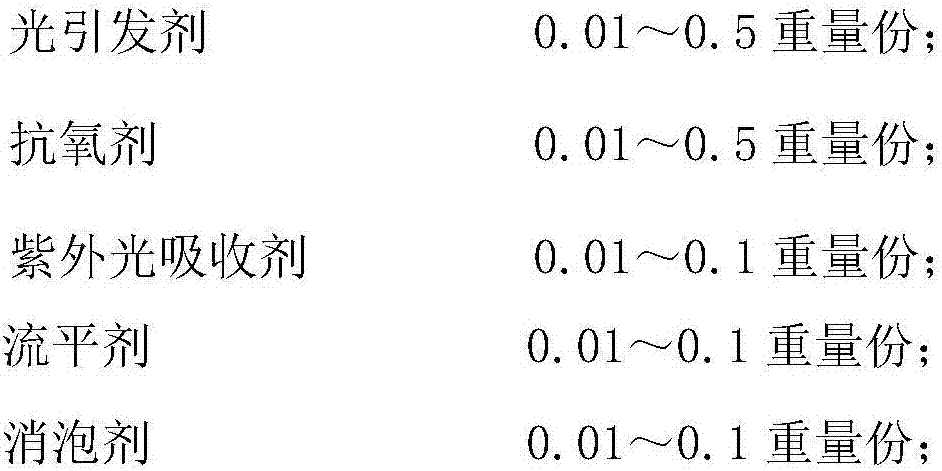

Method used

Image

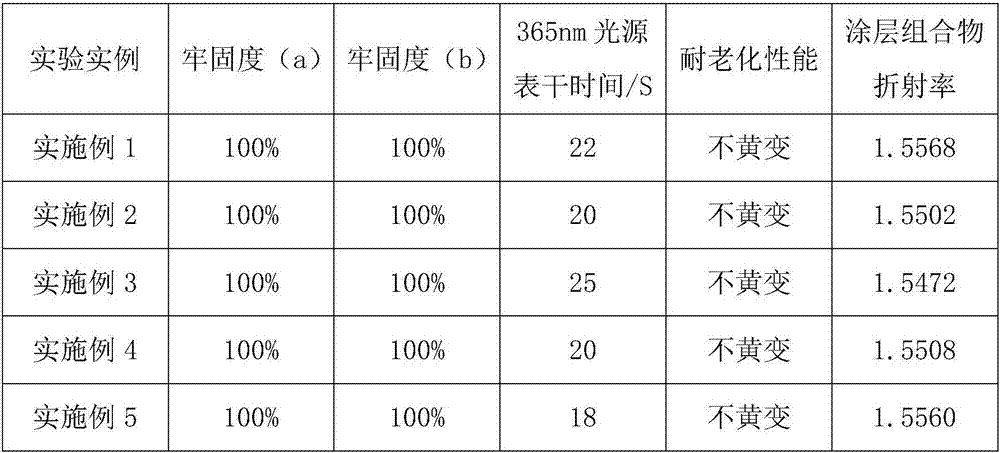

Examples

Embodiment 1

[0043] In a four-neck flask, add 1g 2-mercaptoethanol, 5g PCD1000, 1g PPG400, 2gBSA-F30 and stir evenly, vacuumize at 120°C for 1h, cool down to 50°C, add 0.02g dibutyltin dilaurate and 100g dibutyltin Toluene, then add 5.02g of XDI, keep warm at 70°C until the NCO content is 0.2%, then add 0.002g of 4-methoxyphenol, stir well, add 0.69g of hydroxyethyl methacrylate, keep warm at 70°C until the NCO is 0 , to obtain the product, the measured molecular weight is about 12000, take 10g of the product, add 0.02gBHT, 0.01g UV531, 0.01g BYK-358N, 0.01gBYK-A550, 0.05g1173, and mix well to obtain an unsaturated polyurethane coating composition .

Embodiment 2

[0045] In a four-neck flask, add 1g BEPD, 2g BSA F-30, 1g PPG400, 5gPCL1000 and stir evenly, vacuumize at 120°C for 1h, cool down to 50°C, add 0.02g dibutyltin dilaurate and 100g xylene, Then add 4.98g of IPDI, keep warm at 70°C until the NCO content is 0.2%, then add 0.002g of 4-methoxyphenol, stir evenly, add 0.70g of hydroxypropyl methacrylate, keep warm at 70°C until the NCO is 0, , the measured molecular weight of the obtained product is about 13000, take 10g of the product, add 0.02g BHT, 0.01g UV531, 0.01g BYK-358N, 0.01g BYK-A550, 0.05g1173, and mix well to obtain an unsaturated polyurethane coating composition.

Embodiment 3

[0047] In a four-neck flask, add 1g CHDM, 2g BSA F-30, 1g PPG400, 5gPDA1000 and stir evenly, vacuumize at 120°C for 1h, cool down to 50°C, add 0.02g dibutyltin dilaurate and 100g xylene, Then add 3.26g of HDI, keep warm at 70°C until the NCO content is 0.2%, then add 0.002g of 4-methoxyphenol, stir evenly, add 0.70g of hydroxypropyl methacrylate, keep warm at 70°C until the NCO is 0, , to obtain the product, the measured molecular weight is about 12000, take 10g of the product, add 0.02gBHT, 0.01g UV531, 0.01g BYK-358N, 0.01gBYK-A550, 0.05g1173, and mix well to obtain an unsaturated polyurethane coating composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com