Preparation method of high-water solubility florfenicol powder

A technology of florfenicol powder and florfenicol, applied in the direction of non-active ingredient medical preparations, active ingredient-containing medical preparations, pharmaceutical formulas, etc., can solve complex preparation methods, inclusion rate and yield Unsatisfactory, low production capacity and other problems, to achieve the effect of increasing solubility and stability, improving bioavailability, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

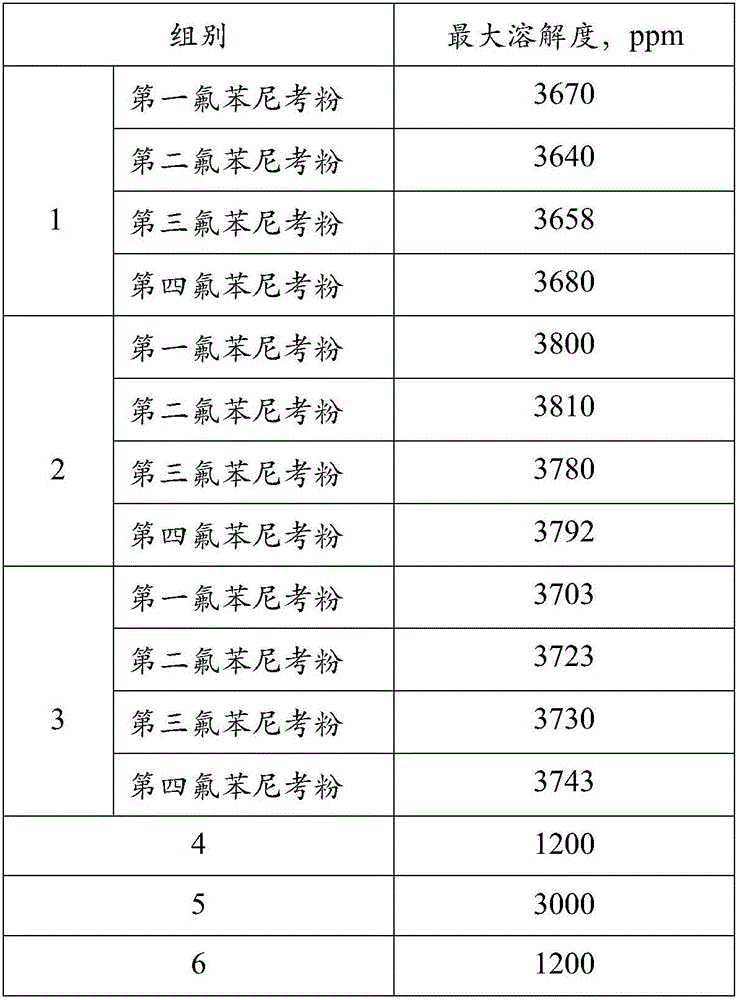

Embodiment 1

[0038] A preparation method of highly water-soluble florfenicol powder, comprising the following steps:

[0039] S1. Add 400 parts by weight of purified water, 200 parts by weight of β-cyclodextrin, and 20 parts by weight of florfenicol into the reaction kettle, stir and heat up to 90°C, keep warm in an environment of 90°C for 2 hours, and keep warm Keep stirring during the process to obtain the first mixed solution;

[0040] S2. Use circulating water to cool the first mixed solution to below 40°C, then use chilled water to cool the first mixed solution to 10°C, keep it warm for 0.5h in an environment of 0°C, and set aside for use, wherein, Keep stirring during the heat preservation process;

[0041] S3. Centrifuge the first mixed solution treated in S2 to obtain a first mixed powder and a first mother liquor, dry and sieve the first mixed powder to obtain a first florfenicol powder.

[0042]S4. Add 400 parts by weight of the first mother liquor, 50 parts by weight of purifi...

Embodiment 2

[0050] A preparation method of highly water-soluble florfenicol powder, comprising the following steps:

[0051] S1. Add 460 parts by weight of deionized water, 224 parts by weight of β-cyclodextrin, and 50 parts by weight of Florfenicol into the reaction kettle, stir and heat up to 90°C, and keep warm in an environment of 92°C for 3h. Keep stirring during the heat preservation process to obtain the first mixed solution;

[0052] S2. Use circulating water to cool the first mixed solution to below 40°C, then use chilled water to cool the first mixed solution to 10°C, keep it warm in an environment of 7°C for 0.5h, and set aside, wherein, Keep stirring during the heat preservation process;

[0053] S3. Centrifuge the first mixed solution treated in S2 to obtain a first mixed powder and a first mother liquor, dry and sieve the first mixed powder to obtain a first florfenicol powder.

[0054] S4. Add 390 parts by weight of the first mother liquor, 80 parts by weight of deionized...

Embodiment 3

[0062] A preparation method of highly water-soluble florfenicol powder, comprising the following steps:

[0063] S1. Add 500 parts by weight of soft water, 250 parts by weight of β-cyclodextrin, and 80 parts by weight of Florfenicol in the reaction kettle, stir and heat up to 90°C, and keep warm for 5 hours in an environment of 95°C. Keep stirring in to obtain the first mixed solution;

[0064] S2. Use circulating water to cool the first mixed solution to below 40°C, then use chilled water to cool the first mixed solution to 10°C, keep it warm at 15°C for 1 hour, and set it aside for later use. stir;

[0065] S3. Centrifuge the first mixed solution treated in S2 to obtain a first mixed powder and a first mother liquor, dry and sieve the first mixed powder to obtain a first florfenicol powder.

[0066] S4. Add 500 parts by weight of the first mother liquor, 100 parts by weight of soft water, 250 parts by weight of β-cyclodextrin, and 80 parts by weight of Florfenicol into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com