High-efficiency ore cleaning, grinding and smashing integrated device

An ore, high-efficiency technology, applied in the field of high-efficiency ore cleaning, grinding, and crushing integrated devices, can solve problems such as low work efficiency, and achieve the effects of convenient processing, accuracy, and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

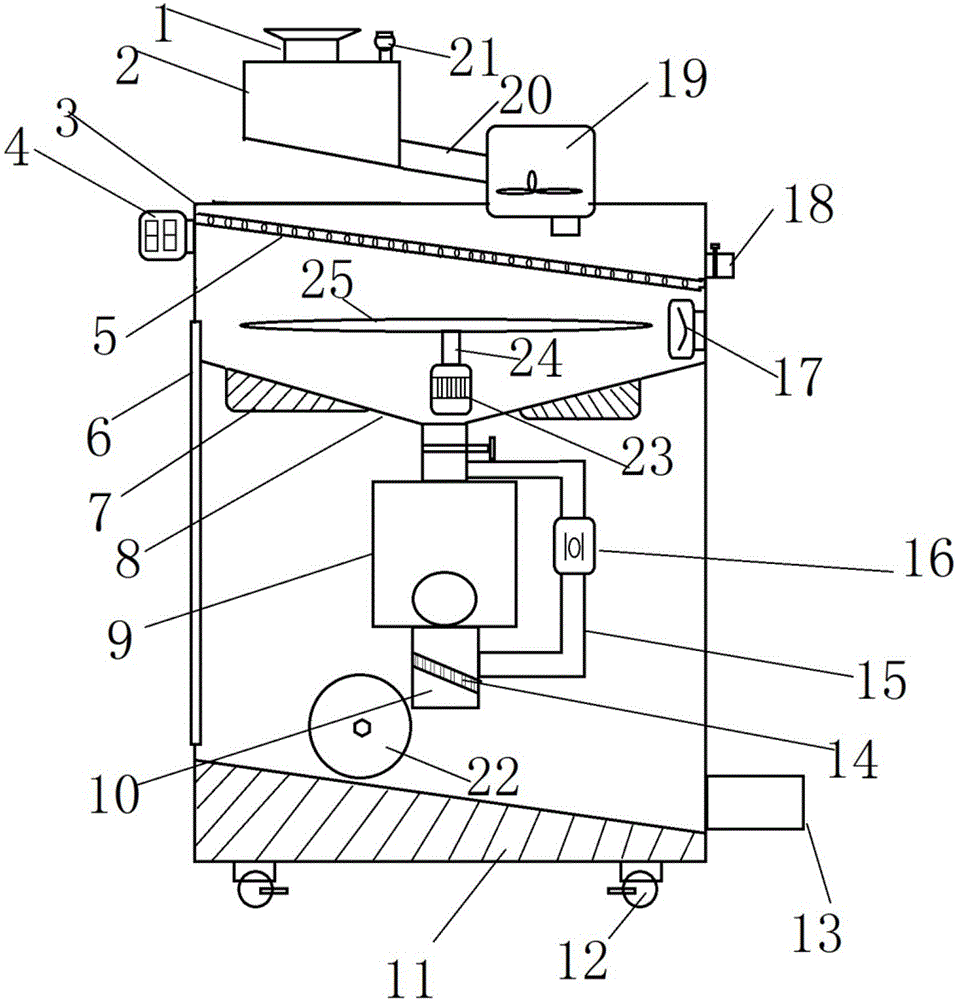

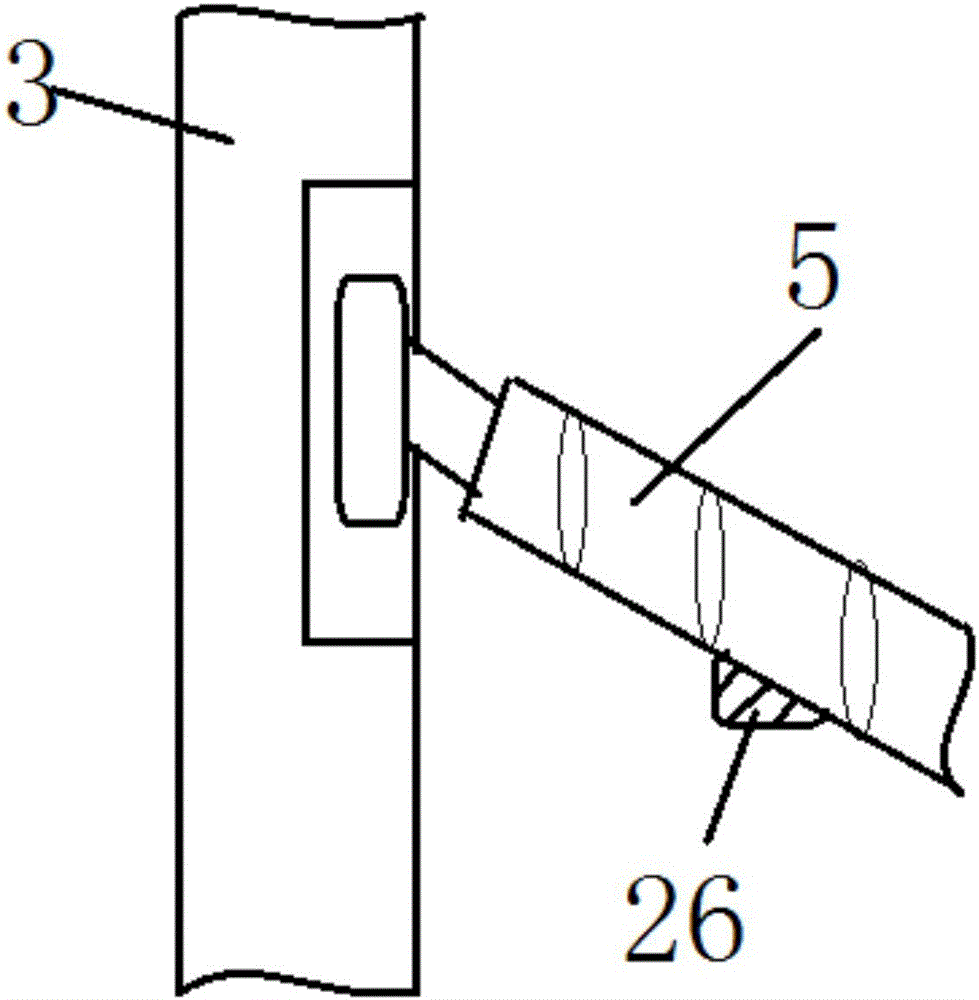

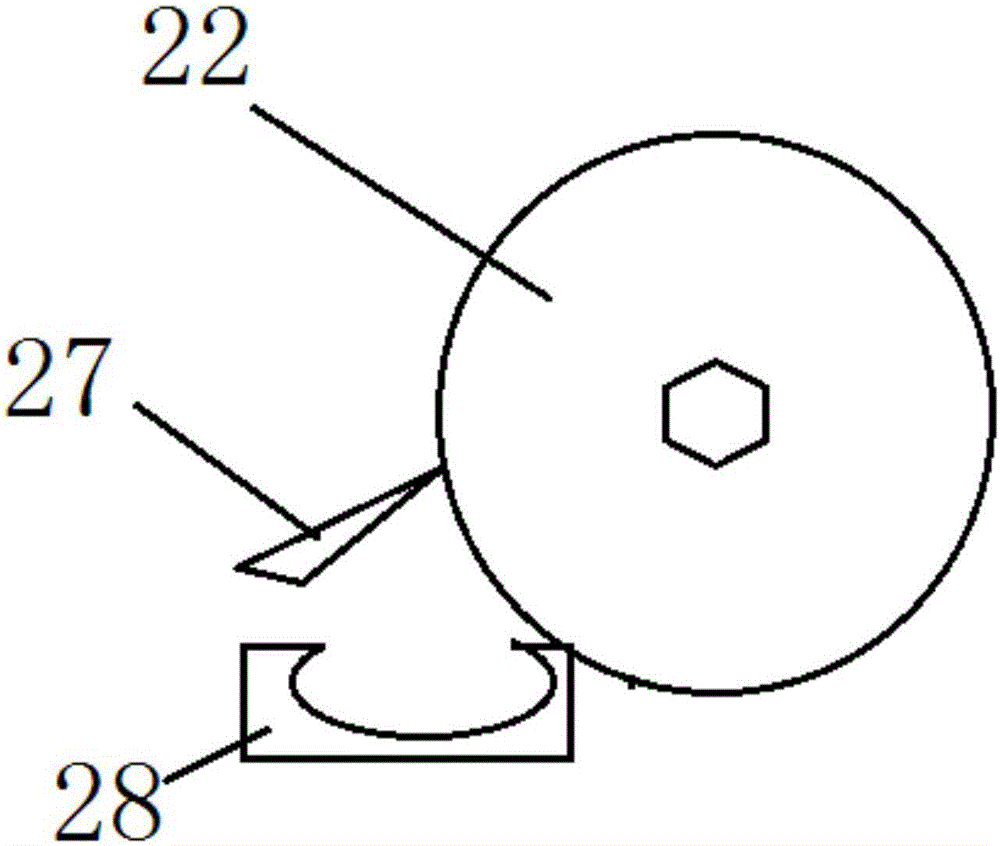

[0020] see Figure 1-4 , a high-efficiency ore cleaning, grinding and crushing integrated device, including an inlet pipe 1, a cleaning tank 2, a box body 3, a sieve plate 5, a transparent glass plate 6, a dryer 7, a collecting bucket 8, a mill 9, and a powder discharge pipe 10. Outlet pipe 13, return pipe 15, solid pump 16, fan 17, crude ore outlet pipe 18 and crusher 19, the top of the cleaning tank 2 is provided with an inlet pipe 1, and the cleaning tank 2 is provided with a chemical addition pipe 21. The cleaning tank 2 communicates with the crusher 19 through the feeding pipe 20. The ore enters the cleaning tank 2 through the inlet pipe 1 for cleaning and soaking. At the same time, appropriate chemical acid can be added through the chemical adding pipe 21. The crusher 19 crushes the ore , to facilitate the next step of the process, the box 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com