Oily sewage reinjection technique without drug feeding treatment

A sewage and process technology, applied in the direction of filtration treatment, special treatment targets, multi-stage water treatment, etc., can solve the problems of heavy burden, etc., and achieve the effect of increasing treatment cost, good degreasing effect, and reducing backwashing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

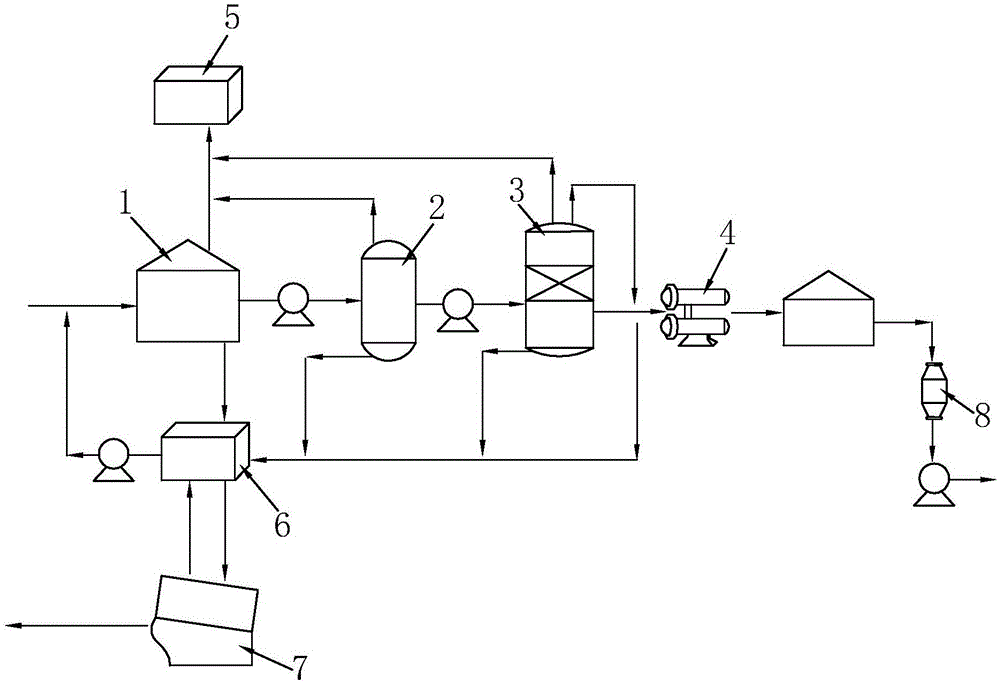

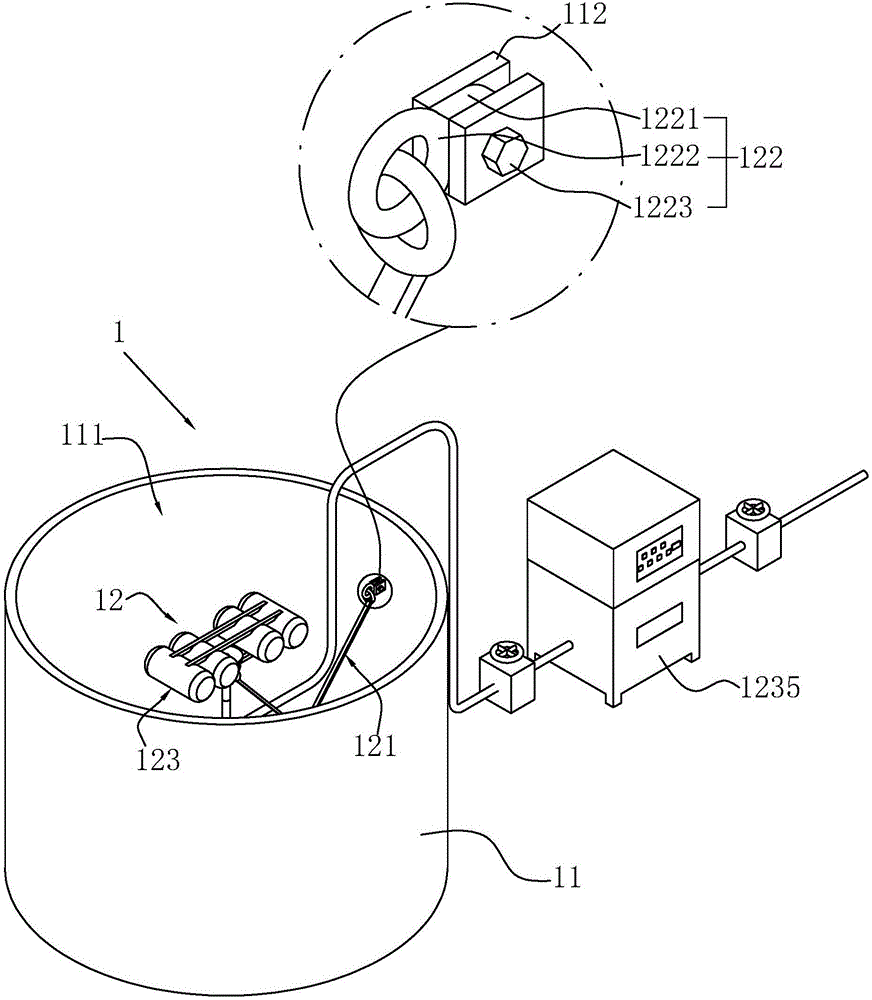

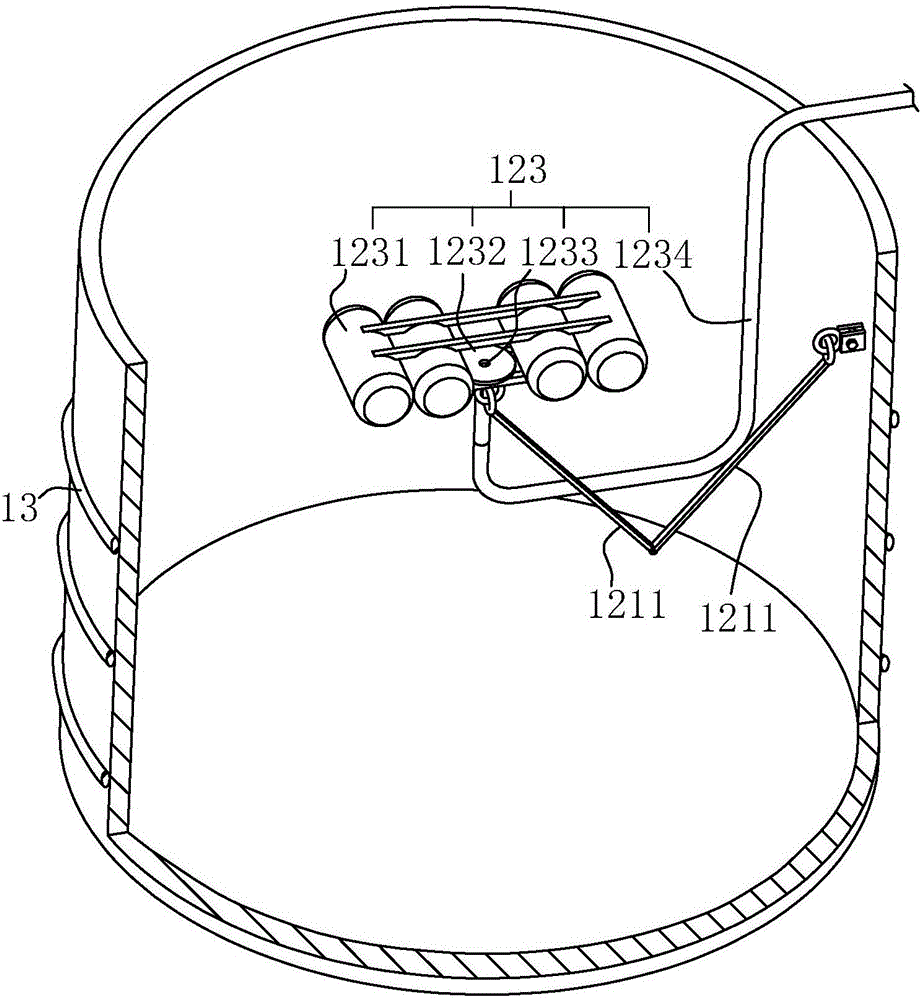

[0040] Embodiment 1: A kind of reinjection system for treating oily sewage without adding medicine, such as figure 1 and figure 2 As shown, it includes a settling oil removal tank 1 , a cyclone purification device 2 , an air flotation filter device 3 and a sterilization device 4 connected in sequence. The oily sewage enters the settling oil removal tank 1 and is divided into oil slick layer and sewage under the action of gravity. The sewage enters the cyclone purification device 2 for further centrifugation to obtain the oil phase and primary separated water. The primary separated water enters the air flotation filter device 3 for further separation to obtain the secondary separated water and oil phase. The oil phase is discharged, and the secondary separated water enters the sterilizing device 4 for disinfection treatment to obtain reinjection water that can be directly recharged. In addition, an oil collection mechanism 12 is provided in the settling oil removal tank 1, ...

Embodiment 2

[0053] Example 2: A process for reinjection of oily sewage without adding chemicals, using the oily sewage reinjection system in Example 1 to detect oily sewage stations in a certain place, wherein the oil content of the oily sewage is about 1.3kg / L. The oily sewage is injected into the sedimentation oil removal tank 1 to separate layers, and an oil collection mechanism 12 is arranged at the liquid injection port of the sedimentation oil removal tank 1 . After 40 minutes of oil recovery treatment, the oil slick collected from the sedimentation oil removal tank 1 appeared to be separated, and then after 20 minutes of oil recovery treatment, oily sewage was obtained. At this time, the oil content in the oily sewage was about 500 mg / L.

[0054] Oily sewage passes through an aeration demulsification device (not shown in the figure, a conventional coalescing plate demulsification device is used), and under the action of air flow, the oil-water interface in the oily sewage is destr...

Embodiment 3

[0067] Example 3: A reinjection process for treating oily sewage without adding chemicals. The oil content in the oily sewage after oil recovery treatment is about 45 mg / L. The specific results after treatment by this process are shown in Table 3.

[0068] Table 3 Analysis of oil content in influent and effluent of oily sewage

[0069]

[0070]

[0071] To treat oily sewage with low oil content, there is no need to add aeration and demulsification process. After this process, the oily sewage can meet the recharge standard, and the sludge treatment rate is as high as 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com