Preparation method of mono-sulfonated Lewis trisaccharide

A single sulfonic and sugar component technology, applied in the preparation of sugar derivatives, chemical instruments and methods, oligosaccharides, etc., can solve the problems of time-consuming and laborious, and achieve the effect of simple preparation method and strong controllability of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

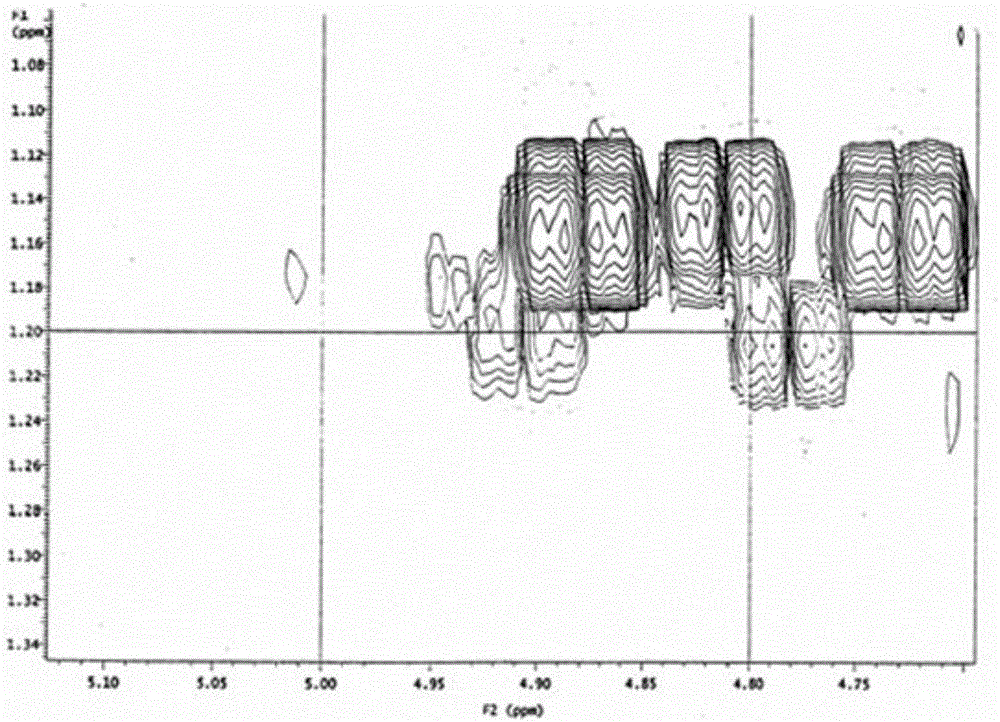

Image

Examples

preparation example Construction

[0017] A preparation method for monosulfonated Lewis trisaccharides, comprising the steps of:

[0018] 1) 300~350mg of 0.3mmol / L 8-p-methoxyphenoxyoctyl 2-acetamido 3-O-(b-D-galactopyranoside) 4-O-(2,3,4 -Tri-O-benzyl a-L-fucopyranoside) 2-deoxy-b-D-glucopyranoside was dissolved in 3~5mL of anhydrous pyridine, and then 85~100mg of 0.6mmol / L sulfur trioxide pyridine was added For the complex compound, mix and stir at 78-82°C for 14-15.5 hours, add toluene, evaporate the co-solvent, and obtain the original residue;

[0019] 2) Dissolving the original residue obtained in step 1) in a mixed solvent of 4 to 5 mL of methanol and acidic acid, adding a palladium or carbon catalyst, stirring at room temperature containing hydrogen for 25 to 32 hours, removing the catalyst and the mixed solvent to obtain a residue;

[0020] 3) Put the residue obtained in step 2) into a DEAE-Sephadex A-50 column, elute with water to remove sulfated sugars, and elute monosulfated sugars with 5% NaCl solu...

Embodiment approach

[0023] As a further embodiment, the preparation method includes the following steps:

[0024] 1) 320 mg of 0.3 mmol / L 8-p-methoxyphenoxyoctyl 2-acetylamino 3-O-(b-D-galactopyranoside) 4-O-(2,3,4-tri -O-benzyl a-L-fucopyranoside) 2-deoxy-b-D-glucopyranoside was dissolved in 3mL of anhydrous pyridine, then added 95mg of 0.6mmol / L sulfur trioxide pyridine complex, at 80 Mix and stir for 15 h at ℃, add toluene, evaporate the co-solvent, and obtain the original residue;

[0025] 2) dissolving the original residue obtained in step 1) in a mixed solvent of 4 mL of methanol and acidic acid, adding a palladium or carbon catalyst, stirring for 30 h at room temperature containing hydrogen, removing the catalyst and mixed solvent to obtain a residue;

[0026] 3) Put the residue obtained in step 2) into a DEAE-Sephadex A-50 column, elute with water to remove sulfated sugars, and elute monosulfated sugars with 5% NaCl solution and 15% NaCl solution respectively. sugar components and sulfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com