Textile auxiliary agent applying graphene in after-finishing procedure

A technology of textile auxiliaries and graphene, which is applied in the direction of textiles and papermaking, fiber treatment, flame-retardant fibers, etc., can solve the problems of static electricity, electric shock, and textile auxiliaries not having antistatic effect in textiles, so as to improve antistatic performance, excellent mechanical properties, and the effect of excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

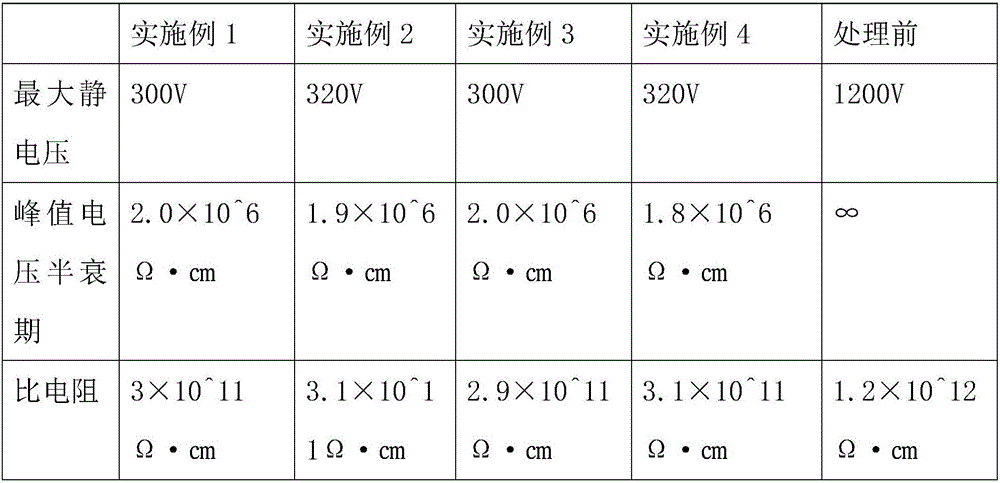

Examples

preparation example Construction

[0027] As a preference, the present invention also discloses a preparation method of the above-mentioned textile auxiliaries using graphene in the finishing process, the specific steps are as follows:

[0028] (1) Take each raw material according to the above mass percentage;

[0029] (2) Mix dioctyl sodium sulfosuccinate, ethyl formamidothiazole acetate, epichlorohydrin, ethylenediamine, dimethylolpropionic acid, and epichlorohydrin at a temperature of 6500-9500r / m Stir for 4-6h in the state;

[0030] (3) Heating the stirred mixed solution to 55-70° C., then adding graphene, foaming agent, flame retardant, basalt fiber, and water, and performing ultrasonication in an ultrasonic machine to prepare a finished product.

[0031] As a preference, in the step (3), the ultrasonic power of the ultrasonic machine is 800w, and the ultrasonic time is 6-8h.

Embodiment 1

[0033] The invention discloses a preparation method of a textile auxiliary agent using graphene in the post-finishing process, and the specific steps are as follows:

[0034] (1) Take each raw material according to the above mass percentage;

[0035] (2) Add 8% sodium dioctyl sulfosuccinate, 7% ethyl formylaminothiazole acetate, 15% epichlorohydrin, 10% ethylenediamine, 8% dimethylol propionic acid, epoxy chloride Mix 10% propane and stir for 5 hours at 6800r / m;

[0036] (3) Heat the stirred mixed solution to 60°C, then add 13% graphene, 7% dicyandiamide, 5% dicyclopentyl methyl phosphate, 1% basalt fiber, and 14% water, and carry out the process in an ultrasonic machine. Ultrasound, the ultrasonic power of the ultrasonic machine is 800w, and the ultrasonic time is 7h, that is, the finished product is prepared.

Embodiment 2

[0038] The invention discloses a preparation method of a textile auxiliary agent using graphene in the post-finishing process, and the specific steps are as follows:

[0039] (1) Take each raw material according to the above mass percentage;

[0040](2) Add 3% sodium dioctyl sulfosuccinate, 12% ethyl formylaminothiazole acetate, 10% epichlorohydrin, 8% ethylenediamine, 13% dimethylol propionic acid, epoxy chloride Mix 5% propane and stir for 5 hours at 7500r / m;

[0041] (3) Heat the stirred mixed solution to 60°C, then add 3% graphene, 7% dicyandiamide, 15% methyl methyl phosphate, 9% basalt fiber, and 15% water, and carry out the process in an ultrasonic machine. Ultrasound, the ultrasonic power of the ultrasonic machine is 800w, and the ultrasonic time is 7h, that is, the finished product is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com