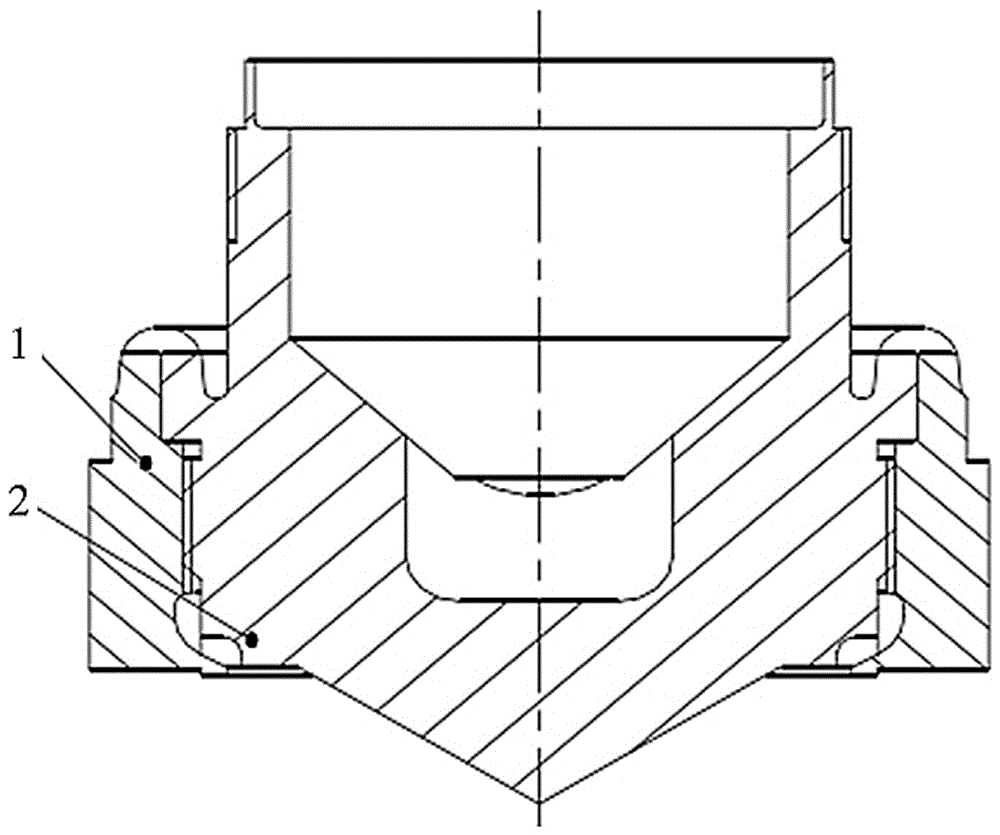

Novel two-sided sealing structure

A sealing structure and double-sided technology, which is applied in the direction of lifting valves, valve details, engine components, etc., can solve the problems of crushing valves and lax closing, and achieve the effects of avoiding crushing or scouring, good sealing performance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Preferably, the valve adopts a reverse flow (top in and bottom out) structure. When the valve is opened and closed, due to the small gap between the sealing surfaces, the pressure difference of the valve (equivalent to the valve inlet pressure) is very large, which causes the medium to flow in the sealing side. The flow velocity is high.

[0012] Preferably, the valve clack adopts a thermal stress compensation structure, which is divided into two bodies, the valve clack and the thermal valve clack. The purpose is to make full use of the thermal deformation of the valve clack to achieve sealing. Tiny elastic action to prevent front leakage.

[0013] Preferably, at the initial stage of the shut-off valve, the valve adopts a reverse flow (top-in and bottom-out) structure, and the annular sealing surface starts to throttle, blocking solid particles from entering the sealing surface of the valve disc and the cone surface of the valve seat. At this time, the maximum flow vel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com