Preparation method and application of Jannus dual-layered ionic imprinting composite film

A technology of ion imprinting and composite membrane, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of high synthesis cost and limited selectivity of special adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

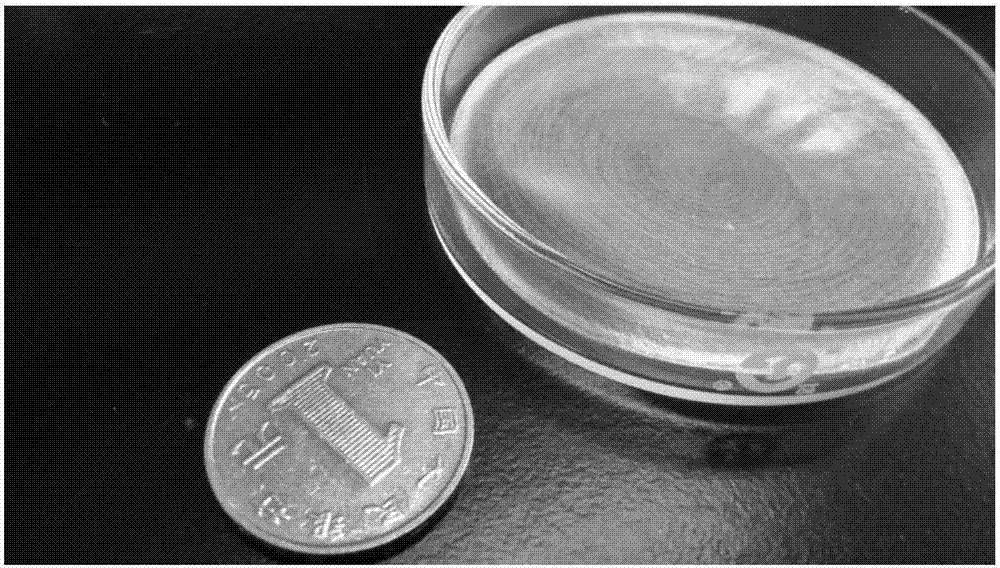

[0045] (1) Take 7mL of the NCC suspension in step (1) after ultrasonic degassing, transfer it into a 25mL round bottom flask, first add 200mg of glucose, stir in a water bath at 60°C for 1h, then add dropwise ethyl orthosilicate TEOS 400 μL, continuously stirred and reacted for 2 hours, and finally poured the reaction solution into an evaporating dish, placed it in a constant temperature water bath to dry, and obtained a colorful and glossy regular nematic film material.

[0046] (2) Take 7mL of the NCC mixed solution in (1) (sonication degassing for 15 minutes before drawing), weigh 0.200g of glucose and 0.0046g of neodymium trichloride hexahydrate, mix and stir for 30 minutes. Then 110 μL of LLYMO-IDA ligand and 280 μL of TEOS, ie tetraethoxysilane, in step (2) were sequentially added in a water bath at 60°C. Finally, the reaction solution was poured into a plate and dried for 6 h after continuous stirring for 2 h. Synthesize the upper dysprosium ion imprinting mixed soluti...

Embodiment 2

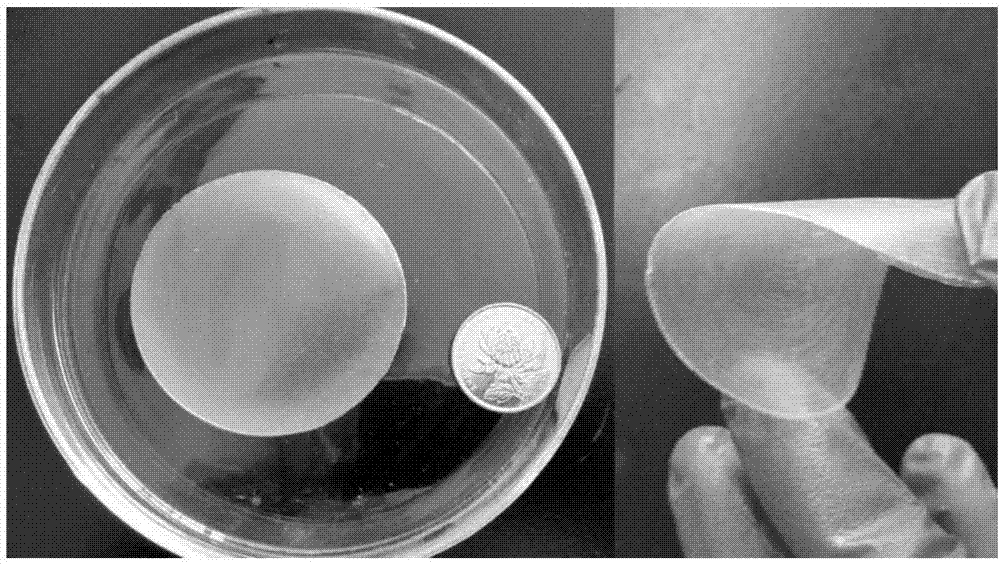

[0053] (1) Weigh 7mL of the NCC mixed solution in step (1) (degassed by ultrasonication for 15min before absorbing), weigh 0.200g of glucose and 0.0046g of neodymium trichloride hexahydrate, and mix and stir for 30min. Then 110 μL of LLYMO-IDA ligand and 280 μL of TEOS, ie tetraethoxysilane, in step (2) were sequentially added in a water bath at 60°C. Finally, the reaction solution was poured into a plate and dried for 6 h after continuous stirring for 2 h. Synthesize the upper dysprosium ion imprinting mixed solution during this period, take a 25mL flask, absorb 7mL of the NCC mixed solution in (1) (ultrasonic degassing for 15min before absorbing), weigh 200mg glucose and 0.0046g dysprosium trichloride hexahydrate, mix Stir for 30min. Then, 7 μL of CPTES-ACAC ligand and 280 μL of TEOS, namely tetraethoxysilane, in step (2) were sequentially added in a water bath at 60°C. Finally, after continuing to stir and react for 2 hours, the reaction solution was placed on a semi-dry ...

Embodiment 3

[0058] (1) Weigh 7mL of the NCC mixed solution in step (1) (degassed by ultrasonication for 15min before absorbing), weigh 0.200g of glucose and 0.0046g of neodymium trichloride hexahydrate, and mix and stir for 30min. Then 110 μL of LLYMO-IDA ligand and 280 μL of TEOS, ie tetraethoxysilane, in step (2) were sequentially added in a water bath at 60°C. Finally, the reaction solution was poured into a plate and dried for 6 h after continuous stirring for 2 h. Synthesize the upper dysprosium ion imprinting mixed solution during this period, take a 25mL flask, draw 7mL of the NCC mixed solution in (1) (ultrasonic degassing for 15min before drawing), weigh 250mg glucose and 0.0023g dysprosium trichloride hexahydrate, mix Stir for 30min. Then 15 μL of CPTES-ACAC ligand and 280 μL of TEOS, ie tetraethoxysilane, in step (2) were sequentially added in a water bath at 60°C. Finally, after continuing to stir and react for 2 hours, the reaction solution was placed on a semi-dry plate, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com