Fluororubber composition

A fluororubber and composition technology, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as difficulty in ensuring sealing performance, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

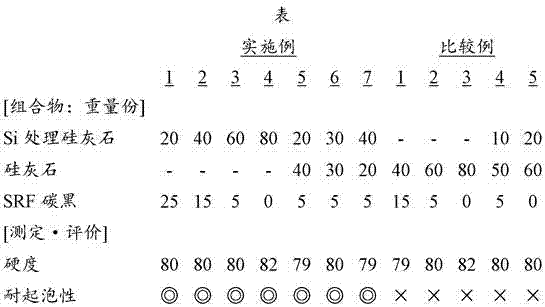

Embodiment 1

[0061] Solid state fluororubber (DuPont products Viton A-500) 80 parts by weight

[0062] Liquid fluororubber (Daikin products Daiel G-101, 20 parts by weight

[0063] Viscosity (100℃) is 1200cps)

[0064] 20 parts by weight of wollastonite treated with silane coupling agent containing epoxy groups

[0065] (NYCO product Wollastcoat 10222, aspect ratio 5)

[0066] SRF carbon black 25 parts by weight

[0067] MgO 3 parts by weight

[0068] Ca(OH) 2 6 parts by weight

[0069] Processing aid (DuPont Dow Elastomers product VPA No. 2) 2 parts by weight

[0070] Bisphenol AF 1.5 parts by weight

[0071] 1.5 parts by weight of quaternary phosphonium salt (Viton VC#20, product of DuPont Company)

[0072] An unvulcanized fluororubber composition is prepared by using any kneading method using an open roll, a kneader, etc. for each of the above components. As a test, the fluororubber composition was extruded and vulcanized at 180° C. for 8 minutes, and then maintained at 230° C...

Embodiment 2

[0078] In Example 1, the amount of silane coupling agent-treated wollastonite was changed to 40 parts by weight, and the amount of SRF carbon black for hardness adjustment (about 80) was changed to 15 parts by weight.

Embodiment 3

[0080] In Example 1, the amount of silane coupling agent-treated wollastonite was changed to 60 parts by weight, and the amount of SRF carbon black for hardness adjustment (about 80) was changed to 5 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com