Beam shaping based hidden added material type laser butt welding method

A beam shaping and butt welding technology, used in laser welding equipment, welding equipment, edge parts of workpieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

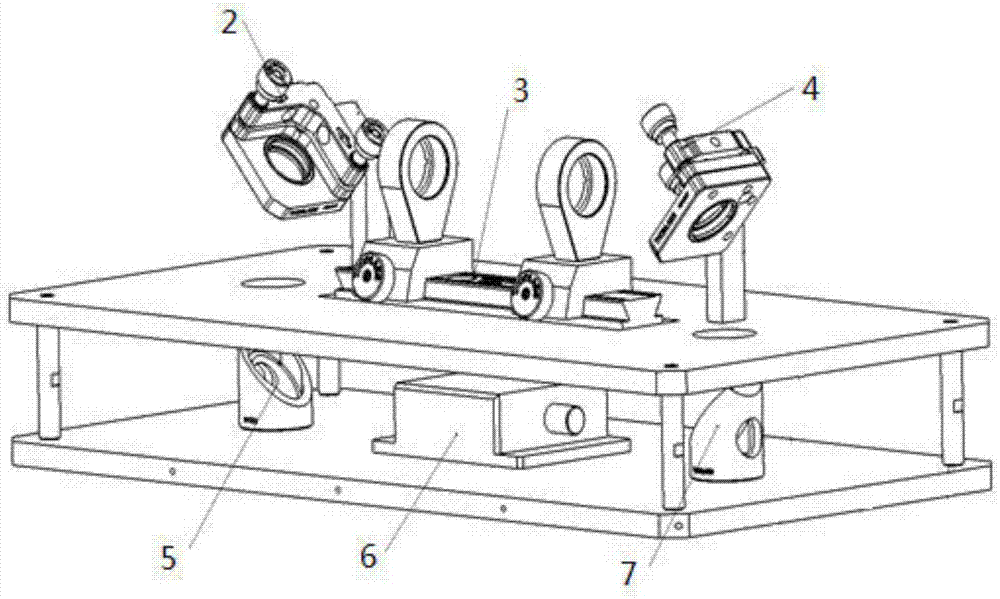

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] The invention provides a laser butt welding method based on beam shaping, which includes the following steps:

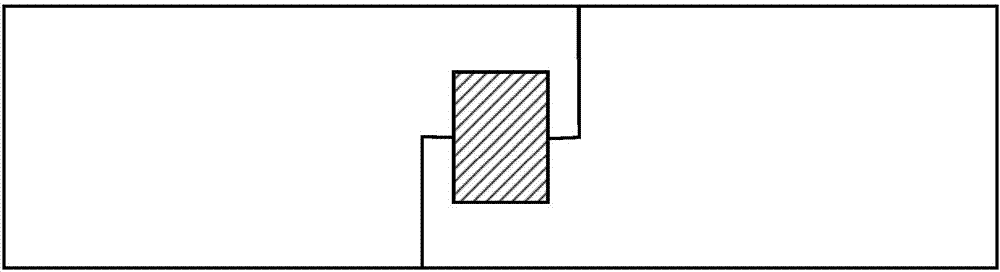

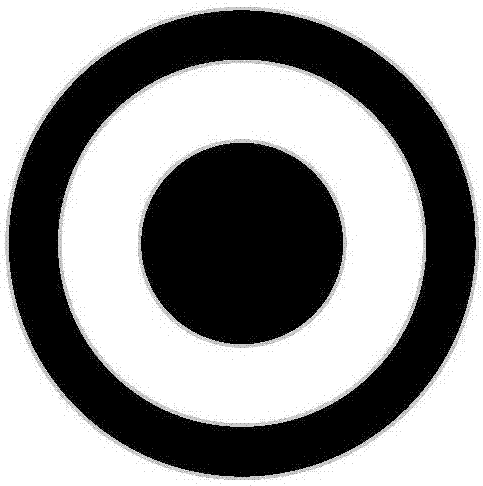

[0023] (1) Clamping the workpiece, setting a welding filling cutout along the welding path at the butt welding joints of the two plate workpieces to be welded, and inserting the welding filling into the welding filling cutout to form a welding with built-in filling structure (such as figure 1 shown), set the relative orientation of the laser welding head and the workpiece, so that the double-circle compound shaping beam output by the laser welding head is vertically incident on the butt welding joint of the workpiece and focused on the surface, and the welding material is located in the double-circle compound Below the inner circular laser irradiation area in the shaping beam;

[0024] The cross-sectional shape of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com