3D printing three-dimensional network structure graphite/metal composite material and its preparation method by atmospheric pressure casting

A metal composite material and network structure technology, which is applied in the field of 3D printing three-dimensional network structure graphite/metal composite material and its atmospheric pressure casting and infiltration preparation field, can solve the problem that it is difficult to obtain network structure composite material, difficult to control the uniformity of graphite distribution, and difficult to improve graphite. Addition and other issues to achieve good strength properties, good lubricity, low corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Hereinafter, the present invention will be described in more detail.

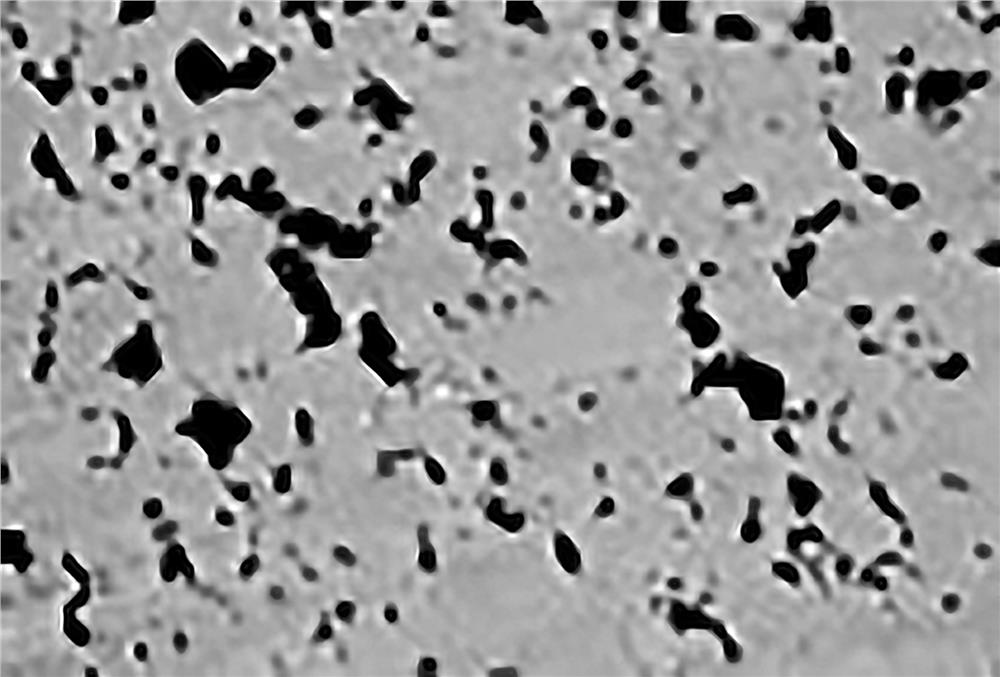

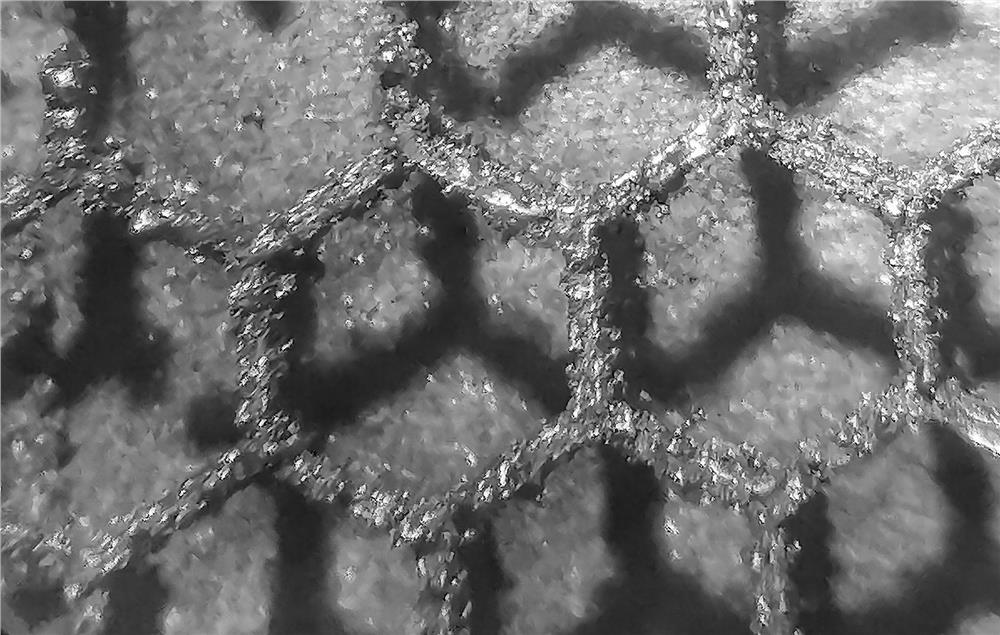

[0024] The 3D printing three-dimensional network structure graphite / metal composite material of the present invention is composed of graphite and metal with an interconnected network structure in three-dimensional space, and the structure type and scale of the graphite network can be changed according to the performance requirements of the product, wherein the graphite The volume ratio is 6% to 35%. In this embodiment, the volume ratio of graphite is specifically 10%. The graphite used is flake graphite with excellent lubricity, thermal conductivity, electrical conductivity, corrosion resistance, low density and thermal expansion. The metal is a cast-infiltrated metal, which can be cast steel, cast iron, cast titanium alloy, cast copper alloy, cast aluminum alloy, or cast magnesium alloy.

[0025] The above-mentioned 3D printing three-dimensional network structure graphite / metal composite material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com