Graphene coordinated continuous glass fiber reinforced halogen-free flame-retardant weather-resistant PPO/HIPS alloy material and preparation method thereof

A continuous glass fiber and alloy material technology, applied in the field of polymer materials, can solve the problems of not meeting the design requirements of high-strength parts and limited mechanical strength, so as to improve rigidity, impact toughness and weather resistance, and improve interface compatibility , Improve the effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

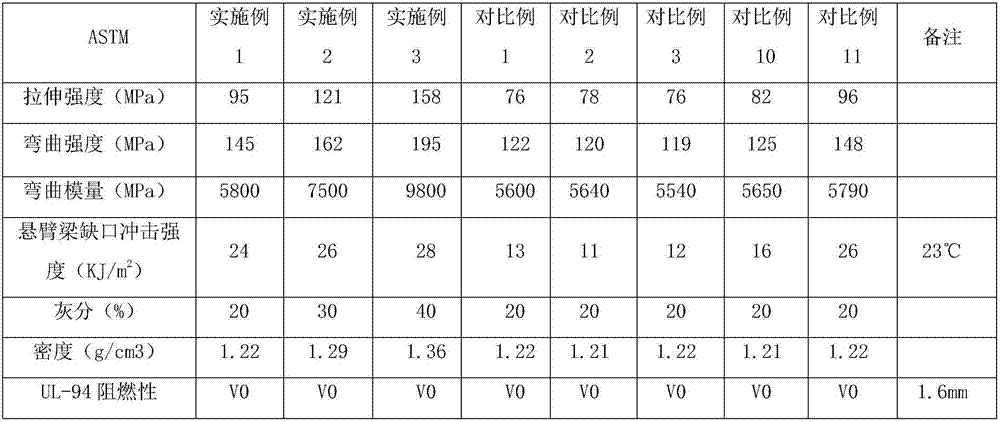

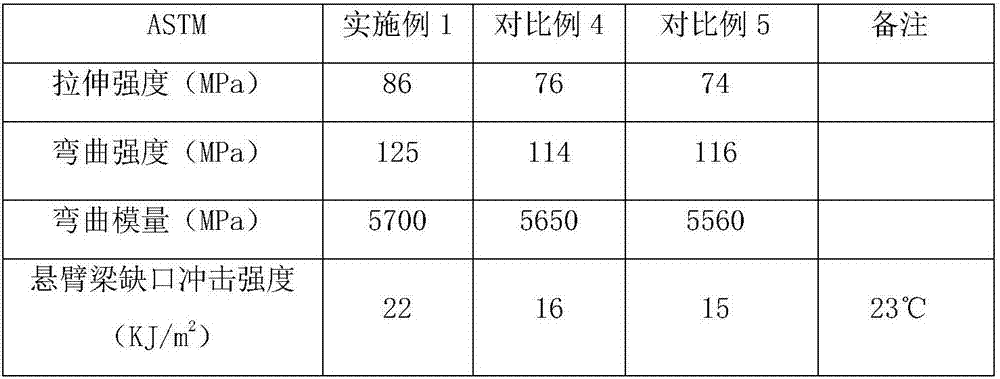

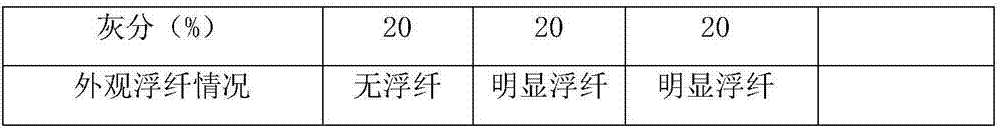

Examples

Embodiment 1

[0038] (1), a graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / HIPS alloy material, the cutting length of the material is 6-25mm, the particle size is 4.0mm, and it includes the following components by weight: PPO 480 320 parts of HIPS, 200 parts of continuous glass fiber, 5 parts of graphene, 10 parts of compatibilizer, 80 parts of toughening agent, 80 parts of flame retardant, 6 parts of antioxidant, 5 parts of compound light stabilizer, lubrication Agent PETS 6 parts, zinc oxide 5 parts;

[0039] (2), a method for preparing graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / HIPS alloy material, comprising the following steps:

[0040] a. Drying preparation: the preheating and drying conditions of PPO are dried at 100-110°C for 3-4 hours, and the preheated drying conditions of HIPS are dried at 80-90°C for 1-2 hours;

[0041] B, mixing preparation: the sil...

Embodiment 2

[0054] (1), a graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / HIPS alloy material, the cutting length of the material is 6-25mm, the particle size is 4.0mm, and it includes the following components by weight: PPO 420 280 parts of HIPS, 300 parts of continuous glass fiber, 10 parts of graphene, 15 parts of compatibilizer, 65 parts of toughening agent, 100 parts of flame retardant, 8 parts of antioxidant, 4 parts of compound light stabilizer, lubricating Agent A-C540A 6 parts, calcium oxide 10 parts;

[0055] (2), a method for preparing graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / HIPS alloy material, comprising the following steps:

[0056] a. Drying preparation: the preheating and drying conditions of PPO are dried at 100-110°C for 3-4 hours, and the preheated drying conditions of HIPS are dried at 80-90°C for 1-2 hours;

[0057] B, mixing preparation...

Embodiment 3

[0065] (1), a graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / HIPS alloy material, the material has a cutting length of 6-25mm and a particle size of 3.0mm, including the following components by weight: PPO:360 parts, HIPS: 240 parts, continuous glass fiber: 400 parts, graphene 15 parts, compatibilizer 20 parts, toughening agent 50 parts, flame retardant 120 parts, antioxidant: 10 parts, compound light stabilizer: 3 parts, lubricant GM-100: 8 parts, zinc oxide 15 parts;

[0066] (2), a method for preparing graphene synergistic continuous glass fiber reinforced halogen-free flame-retardant and weather-resistant PPO / HIPS alloy material, comprising the following steps:

[0067] a. Drying preparation: the preheating and drying conditions of PPO are dried at 100-110°C for 3-4 hours, and the preheated drying conditions of HIPS are dried at 80-90°C for 1-2 hours;

[0068]B, mixing preparation: the silane coupling agent KH...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com